3 bar vs 4 bar map sensor

Related Articles: 3 bar vs 4 bar map sensor

Introduction

With great pleasure, we will explore the intriguing topic related to 3 bar vs 4 bar map sensor. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

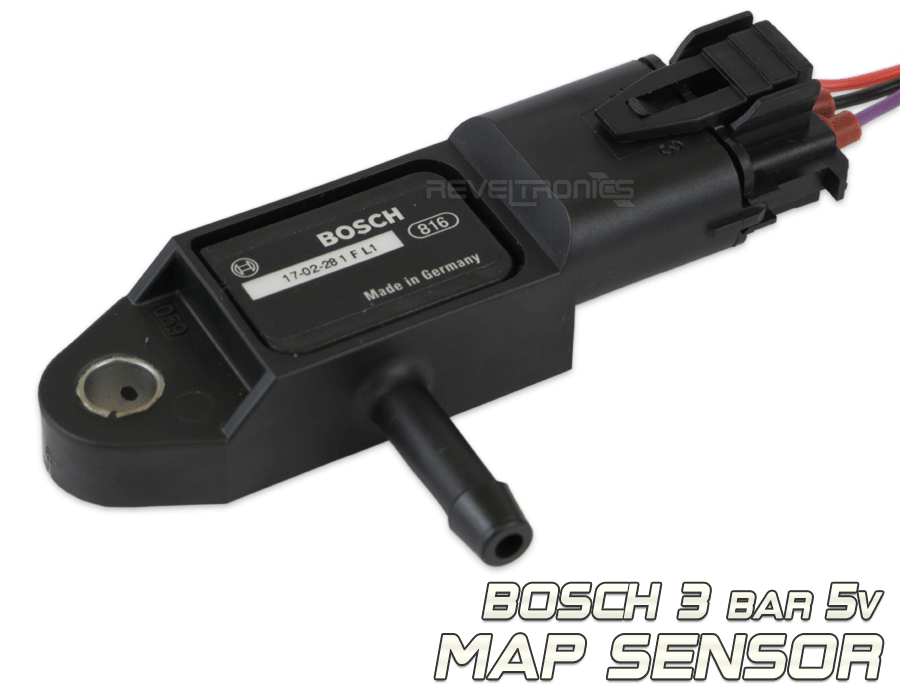

Delving into the Realm of Manifold Absolute Pressure Sensors: 3 Bar vs. 4 Bar

The intricate dance between fuel and air within an internal combustion engine is orchestrated by a multitude of components, each playing a crucial role in ensuring optimal performance. Among these, the Manifold Absolute Pressure (MAP) sensor stands out as a key player, providing vital information about the pressure within the intake manifold. This information is then relayed to the engine control unit (ECU), which in turn adjusts fuel delivery and ignition timing for optimal combustion.

While the fundamental function of a MAP sensor remains constant, variations exist in their design and capabilities, with 3 bar and 4 bar MAP sensors being prominent examples. These differences, seemingly subtle, can have a profound impact on engine performance, particularly in high-performance applications.

Understanding the Essence of a MAP Sensor

A MAP sensor, essentially a pressure transducer, converts the pressure within the intake manifold into an electrical signal that the ECU can interpret. This signal, representing the manifold absolute pressure, is crucial for calculating the air mass entering the engine. The ECU uses this information to determine the optimal amount of fuel to inject for efficient combustion.

The Numerical Distinction: 3 Bar vs. 4 Bar

The numerical designation of a MAP sensor, "3 bar" or "4 bar," refers to its maximum pressure reading capability. A 3 bar MAP sensor can accurately measure pressures up to 3 bar (approximately 43.5 psi), while a 4 bar MAP sensor extends this range to 4 bar (approximately 58 psi). This difference in pressure range translates to a significant difference in the engine’s potential output.

The Implications of Higher Pressure Ranges

A 4 bar MAP sensor, with its ability to measure higher pressures, opens the door to a greater potential for engine performance. This stems from the direct correlation between intake manifold pressure and engine power. Higher manifold pressures, achievable through forced induction (turbochargers or superchargers), translate to greater airflow into the engine, leading to increased power and torque output.

Beyond the Numbers: A Deeper Dive into the Differences

The difference between 3 bar and 4 bar MAP sensors goes beyond their pressure range. While both function on the same principle, their internal design and construction can differ, impacting their accuracy, response time, and overall reliability.

Factors Influencing MAP Sensor Choice

The choice between a 3 bar and 4 bar MAP sensor hinges on several factors, including:

- Engine Type: Naturally aspirated engines typically function within the pressure range of a 3 bar sensor. However, forced induction engines, particularly those with high boost levels, require the wider pressure range of a 4 bar sensor.

- Desired Performance Level: For high-performance applications where maximizing power output is paramount, a 4 bar MAP sensor is often preferred.

- Engine Management System: The ECU’s capabilities and compatibility with specific MAP sensor types should be considered.

FAQs: Addressing Common Queries

Q: Can I upgrade from a 3 bar to a 4 bar MAP sensor?

A: Upgrading to a 4 bar MAP sensor is generally feasible, but it requires careful consideration. Compatibility with the ECU and other engine components must be ensured. Consulting with a qualified mechanic or tuning specialist is highly recommended.

Q: Will upgrading to a 4 bar MAP sensor automatically increase power?

A: A 4 bar MAP sensor alone does not increase power. It simply enables the ECU to accurately measure higher pressures, allowing for more precise fuel delivery and ignition timing adjustments. To achieve increased power, modifications to the engine’s intake and exhaust systems, as well as tuning adjustments, are necessary.

Q: Can I use a 4 bar MAP sensor in a naturally aspirated engine?

A: While technically possible, using a 4 bar MAP sensor in a naturally aspirated engine is not recommended. The sensor will operate within a narrow portion of its range, potentially leading to inaccuracies and reduced performance.

Tips for Maximizing MAP Sensor Performance

- Regular Maintenance: Ensure the MAP sensor is clean and free from debris.

- Proper Installation: Ensure the sensor is securely mounted and connected to the appropriate wiring.

- Calibration: Consult a professional for proper calibration and tuning to optimize sensor performance.

Conclusion: A Vital Component for Optimized Engine Performance

The choice between a 3 bar and 4 bar MAP sensor is a crucial one, directly impacting the engine’s performance and potential. While a 3 bar sensor suffices for naturally aspirated engines, a 4 bar sensor opens the door to greater power and torque in forced induction applications. By understanding the nuances of each sensor type and their impact on engine performance, enthusiasts and professionals alike can make informed decisions to optimize their vehicle’s potential.

Closure

Thus, we hope this article has provided valuable insights into 3 bar vs 4 bar map sensor. We thank you for taking the time to read this article. See you in our next article!