6.7 cummins map sensor location

Related Articles: 6.7 cummins map sensor location

Introduction

With great pleasure, we will explore the intriguing topic related to 6.7 cummins map sensor location. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

The Vital Role of the Manifold Absolute Pressure (MAP) Sensor in 6.7 Cummins Engines: Location, Function, and Maintenance

The 6.7 Cummins engine, a powerhouse known for its reliability and performance, relies on a network of sensors to ensure optimal operation. Among these critical components is the Manifold Absolute Pressure (MAP) sensor, which plays a vital role in determining engine load and adjusting fuel delivery for maximum efficiency and power.

Understanding the MAP Sensor’s Function

The MAP sensor, a crucial element in the engine’s electronic control system, measures the absolute pressure within the intake manifold. This pressure, a direct indicator of engine load, provides valuable information to the engine control module (ECM). The ECM then utilizes this data to calculate the optimal amount of fuel required for combustion, ensuring efficient power delivery while minimizing emissions.

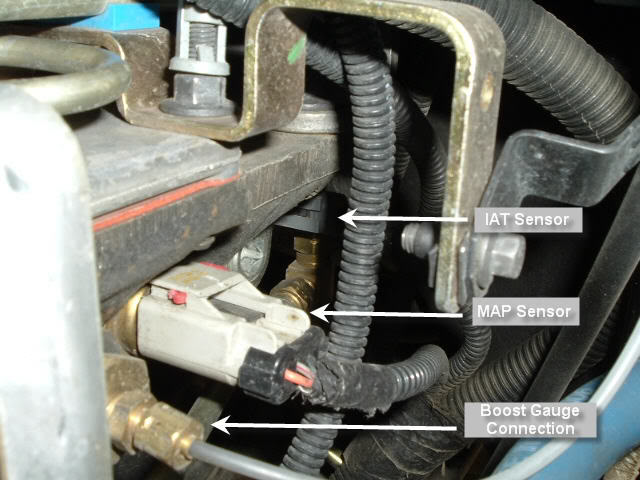

Locating the MAP Sensor in 6.7 Cummins Engines

The MAP sensor’s location can vary slightly depending on the specific model year and configuration of the 6.7 Cummins engine. However, it is typically situated in a readily accessible location within the engine bay, offering convenient access for inspection, maintenance, or replacement.

Common Locations for the 6.7 Cummins MAP Sensor:

- On the Intake Manifold: The MAP sensor is often mounted directly on the intake manifold, typically near the throttle body or the air intake. This placement allows for a direct reading of the manifold pressure.

- On the Engine Block: In some models, the MAP sensor may be mounted on the engine block itself, close to the intake manifold. This location provides a stable and secure mounting point.

- In the Engine Wiring Harness: The MAP sensor can also be integrated into the engine wiring harness, simplifying installation and maintenance.

Identifying the MAP Sensor:

The MAP sensor is typically a small, cylindrical component with a single electrical connector. It may be labeled with "MAP" or "Manifold Absolute Pressure" for easy identification.

The Importance of a Functional MAP Sensor

A malfunctioning MAP sensor can significantly impact engine performance and fuel economy.

Symptoms of a Faulty MAP Sensor:

- Rough Idle: An inaccurate pressure reading can lead to erratic fuel delivery, resulting in a rough idle.

- Poor Acceleration: The engine may struggle to accelerate smoothly due to incorrect fuel delivery.

- Reduced Power: The engine may experience a noticeable loss of power as the ECM receives inaccurate information about engine load.

- Increased Fuel Consumption: An incorrect fuel-air mixture can result in increased fuel consumption.

- Check Engine Light: A malfunctioning MAP sensor will often trigger the check engine light, indicating a problem within the engine’s electronic control system.

Maintaining and Replacing the MAP Sensor

The MAP sensor is a relatively low-maintenance component, but it’s essential to ensure its proper function for optimal engine performance.

Tips for Maintaining the MAP Sensor:

- Regular Inspections: Periodically inspect the MAP sensor for signs of damage, such as cracks, leaks, or corrosion.

- Clean the Sensor: Gently clean the MAP sensor with a clean, dry cloth to remove any accumulated dirt or debris.

- Replace if Necessary: If the MAP sensor exhibits signs of damage or malfunction, it should be replaced promptly.

Replacing the MAP Sensor:

Replacing a faulty MAP sensor is a straightforward process, typically requiring basic hand tools.

Steps for Replacing the MAP Sensor:

- Disconnect the Battery: Disconnect the battery terminals to prevent electrical shocks.

- Locate the MAP Sensor: Identify the MAP sensor’s location using the information provided earlier.

- Disconnect the Electrical Connector: Carefully disconnect the electrical connector from the MAP sensor.

- Remove the Sensor: Unscrew the MAP sensor from its mounting location using the appropriate wrench or socket.

- Install the New Sensor: Install the new MAP sensor in the same location, ensuring a secure connection.

- Reconnect the Electrical Connector: Reconnect the electrical connector to the new MAP sensor.

- Reconnect the Battery: Reconnect the battery terminals.

Frequently Asked Questions (FAQs) about the 6.7 Cummins MAP Sensor:

Q: Can I clean the MAP sensor myself?

A: While cleaning the MAP sensor may seem like a simple solution, it’s generally not recommended. The sensor’s internal components are delicate and can be easily damaged during cleaning. If you suspect a problem with the MAP sensor, it’s best to replace it with a new one.

Q: How often should I replace the MAP sensor?

A: The MAP sensor typically has a long lifespan, but its lifespan can vary depending on the vehicle’s operating conditions and maintenance practices. If you’re experiencing engine problems and suspect the MAP sensor, it’s best to replace it.

Q: What happens if I ignore a faulty MAP sensor?

A: Ignoring a faulty MAP sensor can lead to various problems, including reduced fuel economy, decreased engine power, and even potential damage to the engine. It’s crucial to address a malfunctioning MAP sensor promptly.

Q: Can I reset the check engine light after replacing the MAP sensor?

A: After replacing the MAP sensor, it’s generally recommended to have the check engine light reset by a qualified mechanic using a diagnostic scanner. This ensures that the ECM recognizes the new sensor and clears any stored fault codes.

Conclusion

The MAP sensor is a crucial component in the 6.7 Cummins engine’s electronic control system, playing a vital role in regulating engine load and fuel delivery. Understanding its location, function, and potential issues is essential for maintaining optimal engine performance, fuel economy, and overall reliability. Regular inspections, proper maintenance, and prompt replacement when necessary will ensure that your 6.7 Cummins engine continues to operate at its peak performance.

Closure

Thus, we hope this article has provided valuable insights into 6.7 cummins map sensor location. We appreciate your attention to our article. See you in our next article!