cummins isl 8.9 map sensor

Related Articles: cummins isl 8.9 map sensor

Introduction

With great pleasure, we will explore the intriguing topic related to cummins isl 8.9 map sensor. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

- 1 Related Articles: cummins isl 8.9 map sensor

- 2 Introduction

- 3 Understanding the Cummins ISL 8.9 MAP Sensor: A Comprehensive Guide

- 3.1 The MAP Sensor: A Vital Component in Engine Management

- 3.2 The Importance of the MAP Sensor in the Cummins ISL 8.9 Engine

- 3.3 Common Issues and Troubleshooting Strategies

- 3.4 Frequently Asked Questions (FAQs)

- 3.5 Tips for Maintaining the MAP Sensor

- 3.6 Conclusion

- 4 Closure

Understanding the Cummins ISL 8.9 MAP Sensor: A Comprehensive Guide

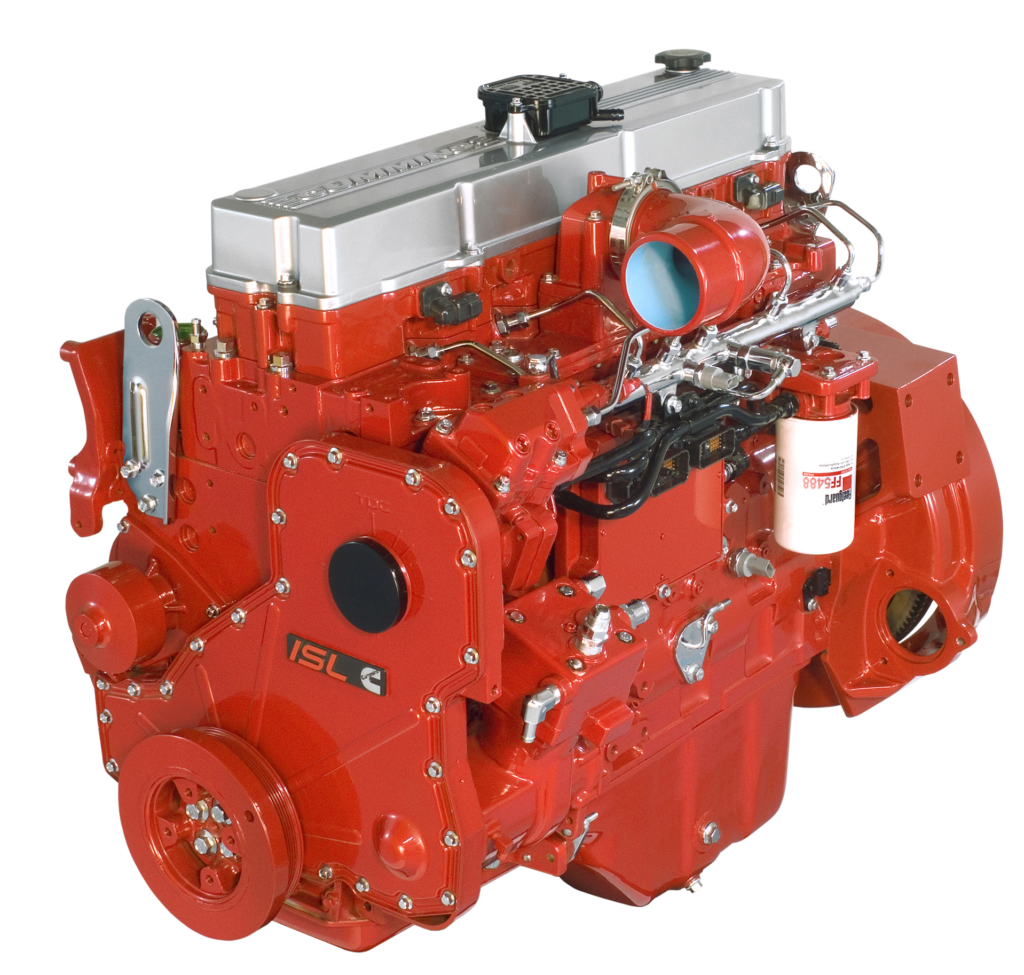

The Cummins ISL 8.9 engine, a powerhouse in the trucking and heavy-duty equipment industries, relies on a sophisticated network of sensors to ensure optimal performance. Among these, the Manifold Absolute Pressure (MAP) sensor plays a crucial role in regulating engine operation and maximizing fuel efficiency. This article delves into the workings of the MAP sensor, its significance in the ISL 8.9 engine, common issues, and troubleshooting strategies.

The MAP Sensor: A Vital Component in Engine Management

The MAP sensor, a critical element in the engine’s Electronic Control Module (ECM), measures the absolute pressure within the intake manifold. This pressure, directly related to the density of air entering the cylinders, provides the ECM with essential data for calculating the ideal fuel-to-air ratio. By accurately sensing manifold pressure, the MAP sensor allows the ECM to:

- Optimize Fuel Injection: The ECM utilizes MAP sensor data to determine the precise amount of fuel to inject into each cylinder, ensuring optimal combustion and maximizing power output.

- Adjust Timing: The sensor readings help the ECM adjust ignition timing, maximizing efficiency and reducing emissions.

- Monitor Boost Pressure: In turbocharged engines, the MAP sensor monitors boost pressure, ensuring safe and efficient operation of the turbocharger.

- Detect Vacuum Leaks: Any leaks in the intake manifold create a drop in pressure, which the MAP sensor detects, alerting the ECM to potential issues.

Understanding the Working Principle:

The MAP sensor, typically a piezoresistive or capacitive device, converts pressure variations into an electrical signal. This signal, interpreted by the ECM, provides a real-time snapshot of the pressure within the intake manifold.

The Importance of the MAP Sensor in the Cummins ISL 8.9 Engine

The Cummins ISL 8.9, a powerful and reliable engine, relies heavily on the MAP sensor for optimal performance. Its significance can be summarized as follows:

- Fuel Efficiency: The MAP sensor enables the ECM to precisely control fuel injection, resulting in optimal combustion and reduced fuel consumption.

- Power Output: Accurate pressure readings allow the ECM to optimize timing and fuel delivery, leading to increased power and torque output.

- Emissions Control: By ensuring optimal combustion, the MAP sensor contributes to reducing harmful emissions, meeting stringent environmental regulations.

- Engine Protection: The sensor detects vacuum leaks, alerting the ECM to potential issues that could damage the engine.

Common Issues and Troubleshooting Strategies

While the MAP sensor is generally robust, it can be susceptible to certain issues, leading to engine performance problems. Some common issues include:

- Sensor Failure: The sensor itself can malfunction, providing inaccurate readings to the ECM.

- Clogged Sensor Ports: Debris or dirt can accumulate in the sensor’s ports, affecting its ability to measure pressure accurately.

- Damaged Wiring: Broken or corroded wiring can disrupt the signal transmission between the sensor and the ECM.

- Vacuum Leaks: Leaks in the intake manifold can distort pressure readings, impacting engine performance.

Troubleshooting Strategies:

- Visual Inspection: Check the sensor for signs of damage, corrosion, or debris buildup.

- Pressure Testing: Use a pressure gauge to verify the sensor’s readings against known pressure values.

- Wiring Inspection: Inspect the wiring for breaks, corrosion, or loose connections.

- Leak Detection: Utilize a smoke test or a vacuum gauge to identify any leaks in the intake manifold.

- Diagnostic Tools: Employ an OBD-II scanner or a Cummins Insite tool to access diagnostic codes and identify potential issues.

Frequently Asked Questions (FAQs)

Q: What are the symptoms of a faulty MAP sensor?

A: A faulty MAP sensor can manifest in various ways, including:

- Engine Misfire: The engine may experience misfires due to incorrect fuel-to-air ratio.

- Rough Idle: The engine may run rough, especially at idle, as the ECM struggles to maintain optimal operation.

- Reduced Power: The engine may experience a loss of power due to inefficient combustion.

- Increased Emissions: The engine may produce excessive smoke or emissions due to incomplete combustion.

- Check Engine Light: The Check Engine Light may illuminate, indicating a fault code related to the MAP sensor.

Q: How often should I replace the MAP sensor?

A: The MAP sensor does not have a specific replacement interval. However, it’s recommended to replace it if it fails or exhibits signs of malfunction.

Q: Can I clean the MAP sensor?

A: It is not recommended to clean a MAP sensor as it can damage the sensitive internal components.

Q: Can I replace the MAP sensor myself?

A: Replacing the MAP sensor is generally a straightforward procedure, but it’s essential to consult the service manual for your specific engine model.

Tips for Maintaining the MAP Sensor

- Regular Inspections: Regularly inspect the sensor for signs of damage or contamination.

- Clean Intake System: Maintain a clean intake system to prevent debris from clogging the sensor ports.

- Avoid Excessive Boost: Avoid exceeding the recommended boost pressure levels, as excessive pressure can damage the sensor.

- Use Quality Parts: When replacing the sensor, use genuine Cummins parts or reputable aftermarket alternatives.

Conclusion

The MAP sensor, a critical component in the Cummins ISL 8.9 engine, plays a vital role in regulating engine operation and maximizing fuel efficiency. By accurately sensing manifold pressure, the sensor allows the ECM to optimize fuel injection, adjust timing, monitor boost pressure, and detect vacuum leaks. Understanding the workings and importance of the MAP sensor, along with troubleshooting strategies and maintenance tips, can help ensure the smooth and efficient operation of the ISL 8.9 engine, contributing to optimal performance, fuel economy, and reduced emissions.

Closure

Thus, we hope this article has provided valuable insights into cummins isl 8.9 map sensor. We hope you find this article informative and beneficial. See you in our next article!