Deciphering the Engine’s Breath: Understanding MAP Sensor Readings on a Scan Tool

Related Articles: Deciphering the Engine’s Breath: Understanding MAP Sensor Readings on a Scan Tool

Introduction

With great pleasure, we will explore the intriguing topic related to Deciphering the Engine’s Breath: Understanding MAP Sensor Readings on a Scan Tool. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

Deciphering the Engine’s Breath: Understanding MAP Sensor Readings on a Scan Tool

The modern automobile engine is a marvel of engineering, a complex system that relies on precise measurements and adjustments to function optimally. One crucial element in this symphony of mechanics is the Manifold Absolute Pressure (MAP) sensor, a vital component responsible for monitoring the pressure within the engine’s intake manifold. This information is then relayed to the engine control unit (ECU), which uses it to fine-tune fuel delivery and ignition timing, ensuring efficient combustion and optimal performance.

Understanding MAP sensor readings on a scan tool is essential for any automotive technician or enthusiast seeking to diagnose and resolve engine-related issues. This article delves into the intricacies of MAP sensor readings, their significance in engine operation, and how to interpret them effectively using a scan tool.

The Role of the MAP Sensor in Engine Management

The MAP sensor, a critical component in modern engine management systems, plays a crucial role in determining the amount of air entering the engine. Its primary function is to measure the absolute pressure within the intake manifold, providing the ECU with real-time data on the engine’s load and air density.

Here’s how the MAP sensor works:

-

Air Intake: As air is drawn into the engine through the intake manifold, the MAP sensor measures the pressure within the manifold. This pressure is directly proportional to the amount of air being drawn into the engine.

-

Sensor Output: The MAP sensor converts the measured pressure into a voltage signal, which is transmitted to the ECU. This voltage signal represents the absolute pressure within the intake manifold.

-

ECU Interpretation: The ECU uses the MAP sensor signal to calculate the amount of air entering the engine. This information is critical for determining the appropriate fuel injection quantity and ignition timing for optimal combustion.

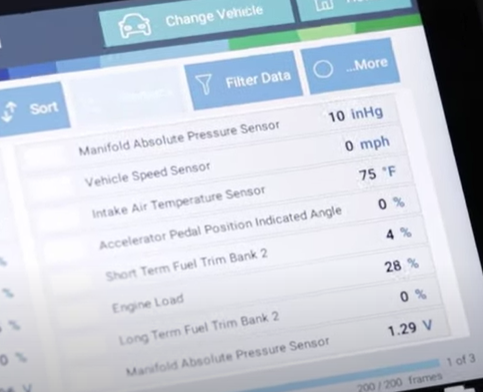

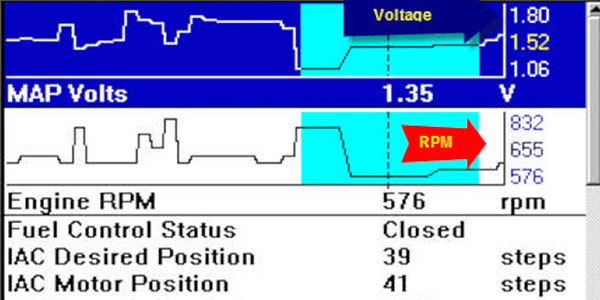

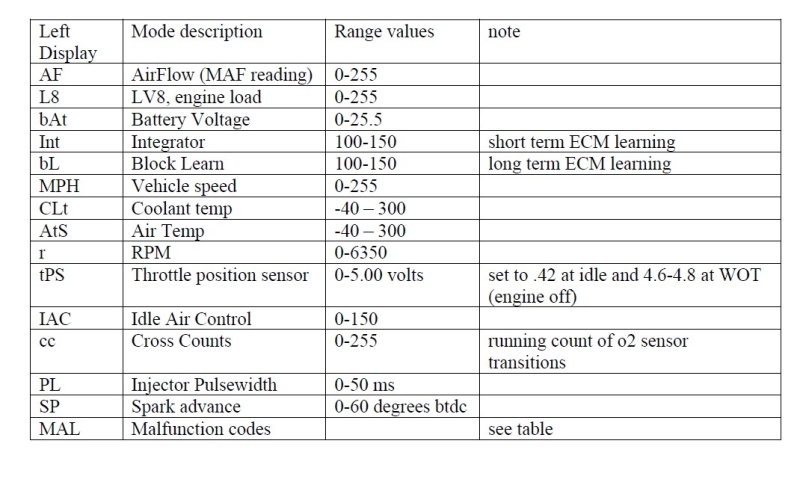

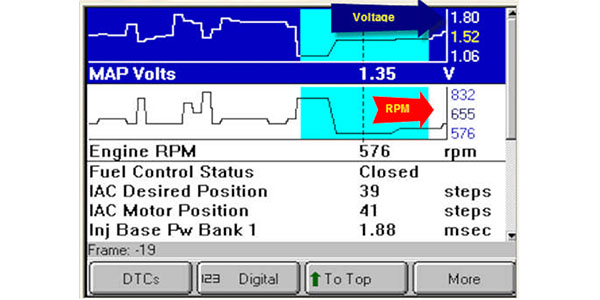

Interpreting MAP Sensor Readings on a Scan Tool

A scan tool provides a window into the engine’s internal workings, allowing technicians to monitor various sensor readings, including the MAP sensor. Understanding how to interpret these readings is crucial for diagnosing engine problems.

Typical MAP Sensor Readings:

- Units: MAP sensor readings are typically displayed in kilopascals (kPa) or inches of mercury (inHg) on a scan tool.

- Idle: At idle, the MAP sensor reading is relatively low, typically between 20 and 40 kPa (0.7 to 1.5 inHg). This indicates a lower air intake volume due to minimal engine load.

- Acceleration: As the engine accelerates, the MAP sensor reading increases, reflecting the higher air intake volume required for increased engine power.

- Boost Pressure: In turbocharged engines, the MAP sensor reading can be significantly higher, indicating the increased pressure created by the turbocharger.

Analyzing MAP Sensor Readings for Troubleshooting

By comparing the MAP sensor readings to expected values and observing their behavior under various conditions, technicians can identify potential issues:

- High MAP Sensor Reading: A higher-than-expected MAP sensor reading can indicate a vacuum leak, a restricted exhaust system, or a problem with the turbocharger (in turbocharged engines).

- Low MAP Sensor Reading: A lower-than-expected MAP sensor reading can indicate a restricted intake manifold, a faulty MAP sensor, or a problem with the air intake system.

- Fluctuating MAP Sensor Reading: Fluctuations in the MAP sensor reading can indicate a vacuum leak, a malfunctioning MAP sensor, or an issue with the intake manifold.

Common MAP Sensor Problems and Troubleshooting

MAP sensors, like any electronic component, can experience malfunctions. Recognizing these issues is essential for effective troubleshooting.

- Faulty MAP Sensor: A faulty MAP sensor can provide inaccurate readings to the ECU, leading to engine performance problems.

- Vacuum Leak: A vacuum leak in the intake manifold can cause a higher-than-expected MAP sensor reading, disrupting the ECU’s calculations and leading to engine performance issues.

- Restricted Intake or Exhaust: Obstructions in the intake or exhaust systems can affect the pressure within the intake manifold, resulting in inaccurate MAP sensor readings.

Tips for Troubleshooting MAP Sensor Issues

- Visual Inspection: Begin by visually inspecting the MAP sensor for any signs of damage, corrosion, or loose connections.

- Vacuum Test: Perform a vacuum test to check for leaks in the intake manifold.

- Pressure Test: Use a pressure gauge to check for restrictions in the intake or exhaust systems.

- Scan Tool Data Review: Analyze the MAP sensor readings on a scan tool to identify any unusual patterns or deviations from expected values.

- Sensor Replacement: If the MAP sensor is suspected to be faulty, replace it with a new, genuine OEM part.

FAQs About MAP Sensor Readings

1. Why is the MAP sensor reading fluctuating?

Fluctuations in the MAP sensor reading can be caused by a vacuum leak, a malfunctioning MAP sensor, or an issue with the intake manifold.

2. What happens if the MAP sensor is faulty?

A faulty MAP sensor can provide inaccurate readings to the ECU, leading to engine performance issues such as rough idle, stalling, poor acceleration, and increased fuel consumption.

3. How can I test the MAP sensor?

The most effective way to test a MAP sensor is by using a scan tool to monitor its readings while the engine is running. Compare the readings to expected values and observe their behavior under various conditions. You can also use a multimeter to measure the voltage output of the MAP sensor.

4. How do I reset the ECU after replacing the MAP sensor?

After replacing the MAP sensor, it is generally recommended to disconnect the battery for a few minutes to reset the ECU. This allows the ECU to re-learn the engine’s parameters with the new sensor.

5. What are the symptoms of a vacuum leak?

A vacuum leak can cause a higher-than-expected MAP sensor reading, leading to symptoms such as rough idle, poor acceleration, and increased fuel consumption.

6. How can I identify a vacuum leak?

A vacuum leak can be identified by listening for hissing sounds around the intake manifold, visually inspecting for cracks or loose connections, and using a vacuum gauge to check for pressure drops.

Conclusion

The MAP sensor plays a critical role in ensuring optimal engine performance by providing the ECU with real-time information about the air intake volume. Understanding MAP sensor readings on a scan tool is essential for diagnosing engine problems and ensuring efficient operation. By carefully analyzing these readings and comparing them to expected values, technicians can pinpoint potential issues, diagnose malfunctions, and implement effective solutions.

The ability to interpret MAP sensor data effectively is a valuable skill for any automotive professional, enabling them to maintain optimal engine performance and provide efficient repairs. By understanding the intricacies of MAP sensor operation and its role in engine management, technicians can navigate the complexities of modern automotive systems with confidence and precision.

Closure

Thus, we hope this article has provided valuable insights into Deciphering the Engine’s Breath: Understanding MAP Sensor Readings on a Scan Tool. We appreciate your attention to our article. See you in our next article!