Deciphering the Pressure: A Comprehensive Guide to 2-Bar and 3-Bar MAP Sensors

Related Articles: Deciphering the Pressure: A Comprehensive Guide to 2-Bar and 3-Bar MAP Sensors

Introduction

With great pleasure, we will explore the intriguing topic related to Deciphering the Pressure: A Comprehensive Guide to 2-Bar and 3-Bar MAP Sensors. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

Deciphering the Pressure: A Comprehensive Guide to 2-Bar and 3-Bar MAP Sensors

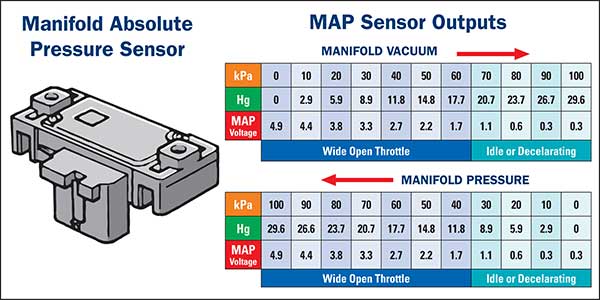

In the intricate world of automotive engineering, the manifold absolute pressure (MAP) sensor plays a crucial role in determining engine performance and fuel efficiency. This sensor, nestled within the engine’s intake manifold, meticulously measures the pressure of the air entering the cylinders. This information, transmitted to the engine control unit (ECU), serves as a vital input for calculating fuel injection timing and duration, ultimately influencing the engine’s combustion process.

The accuracy and range of this pressure measurement are directly tied to the type of MAP sensor employed. While both 2-bar and 3-bar MAP sensors fulfill the primary function of pressure detection, their capabilities and applications differ significantly, impacting engine performance and tuning potential.

Understanding the Pressure Scale: A Barometer of Performance

The numerical designation of a MAP sensor, such as 2-bar or 3-bar, directly reflects its pressure measurement range. A 2-bar MAP sensor, for instance, can accurately measure pressure up to 2 atmospheres (bar), while a 3-bar sensor extends this range to 3 atmospheres. This seemingly subtle difference in measurement capacity holds profound implications for engine performance and tuning.

The 2-Bar MAP Sensor: A Reliable Workhorse for Everyday Performance

A 2-bar MAP sensor, commonly found in naturally aspirated engines and some turbocharged vehicles, is designed to handle the typical pressures encountered in everyday driving. It provides accurate readings within its operating range, enabling the ECU to precisely control fuel delivery and ignition timing. The 2-bar sensor, with its proven reliability and cost-effectiveness, remains a popular choice for various automotive applications.

The 3-Bar MAP Sensor: Unleashing Higher Performance Potential

The 3-bar MAP sensor, often found in high-performance engines and turbocharged vehicles, is engineered to handle significantly higher pressure levels. This enhanced capability allows the sensor to accurately measure the increased boost pressure generated by turbochargers, superchargers, or nitrous oxide systems. With its expanded range, the 3-bar sensor empowers the ECU to precisely control fuel delivery and ignition timing even under extreme conditions, unlocking greater performance potential.

The Importance of Sensor Selection: Matching the Sensor to the Application

Choosing the right MAP sensor is crucial for optimal engine performance and tuning. Using a 2-bar sensor in a high-boost application can lead to inaccurate pressure readings, causing the ECU to misinterpret the data, potentially leading to engine damage or inefficient performance. Conversely, installing a 3-bar sensor in a naturally aspirated engine, where the pressure range remains within 2 bars, might be overkill, offering no tangible benefits while potentially increasing cost.

Beyond the Pressure: Exploring the Nuances of MAP Sensor Selection

While the pressure range is a primary factor in sensor selection, other considerations can further influence the decision. These include:

- Engine Type: Naturally aspirated engines typically operate within the 2-bar pressure range, while turbocharged or supercharged engines often require a 3-bar sensor to accommodate the higher boost pressures.

- Tuning Goals: For performance enthusiasts seeking to push the limits of their engines, a 3-bar sensor can provide greater accuracy and control under high-boost conditions, enabling more aggressive tuning.

- Cost: 3-bar sensors generally cost more than their 2-bar counterparts due to their enhanced capabilities and manufacturing complexity.

FAQs: Addressing Common Queries about MAP Sensors

Q: Can I swap a 2-bar MAP sensor for a 3-bar sensor?

A: While physically swapping the sensors is possible, it is not recommended without proper ECU calibration. The ECU is programmed to interpret data from the specific sensor type installed. Changing the sensor without recalibrating the ECU can lead to inaccurate readings and potential engine damage.

Q: What are the signs of a failing MAP sensor?

A: Common symptoms include:

- Rough idle

- Poor fuel economy

- Engine hesitation or stalling

- Check engine light illumination

Q: How do I test a MAP sensor?

A: Testing a MAP sensor involves checking its resistance and comparing it to the manufacturer’s specifications. A multimeter can be used to perform this test. However, it is crucial to consult the vehicle’s repair manual or seek professional assistance for accurate diagnosis.

Q: Can I clean a MAP sensor?

A: Cleaning a MAP sensor is generally not recommended as it can damage the delicate sensor element. If the sensor is dirty, it’s best to replace it with a new one.

Tips for Optimizing MAP Sensor Performance

- Regular Inspection: Regularly inspect the MAP sensor for signs of damage or contamination.

- Clean Intake System: Maintain a clean intake system to prevent dust and debris from accumulating on the sensor.

- Proper Installation: Ensure the MAP sensor is properly installed and secured to avoid leaks or damage.

- Professional Calibration: If modifying the engine or swapping sensors, consult a professional for proper ECU calibration.

Conclusion: A Vital Component for Engine Performance and Tuning

The MAP sensor, whether a 2-bar or 3-bar variant, plays a pivotal role in modern engine management systems. Understanding the nuances of these sensors and their respective pressure ranges is essential for optimizing engine performance and tuning. By selecting the appropriate sensor and ensuring its proper operation, drivers can unlock the full potential of their vehicles while maintaining optimal fuel efficiency and reliability.

Closure

Thus, we hope this article has provided valuable insights into Deciphering the Pressure: A Comprehensive Guide to 2-Bar and 3-Bar MAP Sensors. We thank you for taking the time to read this article. See you in our next article!