Delving into the Differences: MAF and MAP Sensors in Automotive Systems

Related Articles: Delving into the Differences: MAF and MAP Sensors in Automotive Systems

Introduction

In this auspicious occasion, we are delighted to delve into the intriguing topic related to Delving into the Differences: MAF and MAP Sensors in Automotive Systems. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

Delving into the Differences: MAF and MAP Sensors in Automotive Systems

The intricate dance of combustion within a vehicle’s engine relies on a delicate balance of air and fuel. To achieve this optimal blend, modern automobiles employ sophisticated sensors that monitor critical parameters. Two such sensors, the Mass Air Flow (MAF) sensor and the Manifold Absolute Pressure (MAP) sensor, play crucial roles in this intricate process, yet they are fundamentally distinct in their function and operation.

Understanding the MAF Sensor: A Window into Airflow

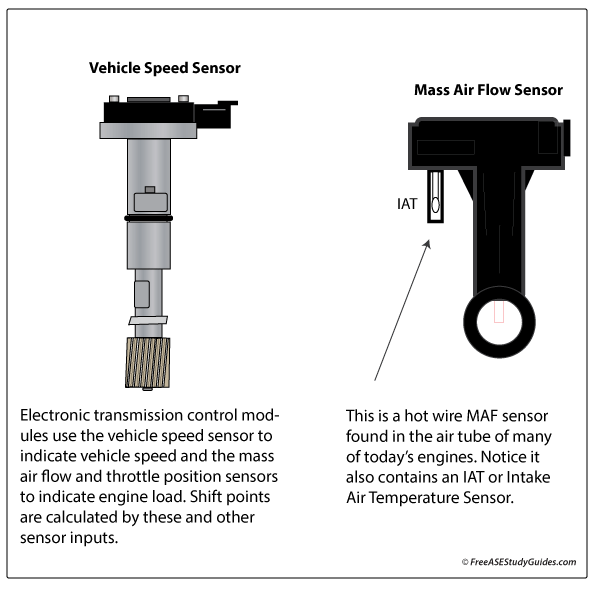

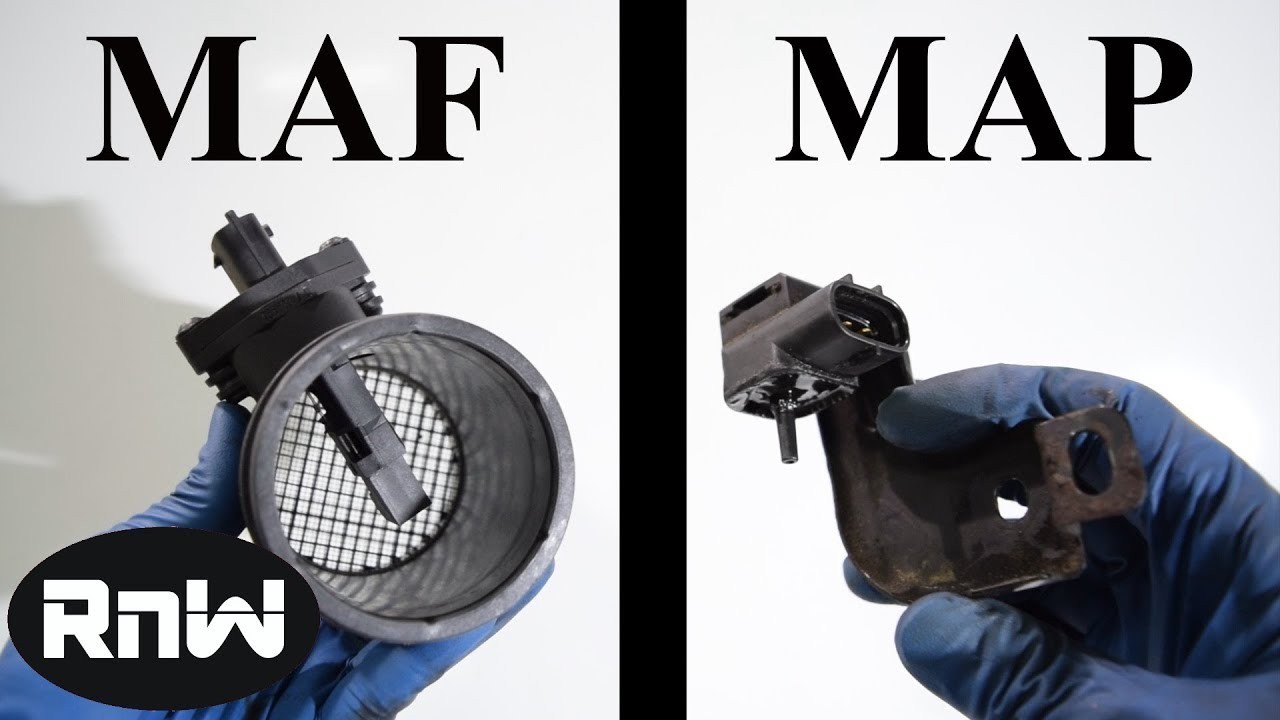

The MAF sensor, strategically positioned in the intake manifold, acts as a crucial intermediary in the fuel delivery system. Its primary function is to measure the mass of air entering the engine. This measurement is vital for the engine control unit (ECU), which then calculates the appropriate amount of fuel to inject for optimal combustion.

The MAF sensor operates on the principle of hot-wire anemometry. A heated wire element within the sensor is exposed to the incoming airflow. As air passes over the wire, it cools down. The sensor measures the amount of electrical current required to maintain the wire at a constant temperature. This current is directly proportional to the mass of air flowing through the sensor.

The MAP Sensor: Gauging Intake Manifold Pressure

In contrast to the MAF sensor’s focus on airflow, the MAP sensor monitors the pressure within the intake manifold. This pressure, known as manifold absolute pressure, is a direct indication of the amount of air present in the manifold.

The MAP sensor typically employs a piezoresistive sensor, a device that changes its electrical resistance in response to pressure variations. As pressure within the intake manifold fluctuates, the MAP sensor registers these changes and transmits them to the ECU.

Distinct Roles in the Engine Control System

While both MAF and MAP sensors contribute to the smooth operation of the engine, their roles are distinct and complementary:

- MAF sensor: Provides a real-time measurement of the mass of air entering the engine. This information is crucial for calculating the precise fuel injection quantity.

- MAP sensor: Measures the pressure within the intake manifold, providing an indirect measure of the air density present. This information is used by the ECU to adjust parameters such as ignition timing and fuel delivery.

Why Two Sensors? The Case for Redundancy and Adaptability

The presence of both MAF and MAP sensors in many modern vehicles reflects a strategy of redundancy and adaptability:

- Redundancy: If one sensor fails, the other can provide the necessary information to the ECU, ensuring the engine continues to operate, albeit with some performance limitations.

- Adaptability: In certain engine configurations, such as those with variable intake manifold designs, the MAP sensor provides valuable information about the manifold pressure, allowing the ECU to fine-tune the fuel delivery system for optimal performance.

Commonalities and Differences

Although the MAF and MAP sensors have distinct functions, they share some commonalities:

- Analog Output: Both sensors typically output an analog signal, representing the measured parameter, to the ECU.

- Importance for Fuel Delivery: Both sensors play a critical role in ensuring the correct air-fuel mixture for optimal combustion.

However, significant differences exist between the two sensors:

- Measurement Principle: The MAF sensor measures airflow directly, while the MAP sensor measures manifold pressure indirectly.

- Location: The MAF sensor is positioned in the intake manifold, while the MAP sensor is typically located on the intake manifold itself.

- Sensitivity: The MAF sensor is highly sensitive to changes in airflow, while the MAP sensor is more sensitive to changes in manifold pressure.

The Impact of Sensor Malfunctions

A malfunctioning MAF or MAP sensor can significantly impact engine performance and fuel efficiency. Here’s how:

- MAF Sensor Failure: A faulty MAF sensor can lead to an inaccurate measurement of airflow, resulting in either too much or too little fuel being injected. This can manifest as rough idling, poor acceleration, increased fuel consumption, and even engine stalling.

- MAP Sensor Failure: A malfunctioning MAP sensor can cause inaccurate pressure readings, leading to problems with ignition timing and fuel delivery. This can result in poor engine performance, reduced power, and increased emissions.

FAQs: Addressing Common Questions

Q: Can I replace the MAF sensor with a MAP sensor?

A: No, the MAF and MAP sensors are not interchangeable. They measure different parameters and are designed to work with specific engine control systems.

Q: How do I know if my MAF or MAP sensor is faulty?

A: Several symptoms can indicate a malfunctioning sensor, including:

* **Rough idling:** The engine may idle unevenly or stall.

* **Poor acceleration:** The engine may hesitate or struggle to accelerate.

* **Increased fuel consumption:** The vehicle may use more fuel than usual.

* **Check engine light:** The check engine light may illuminate, indicating a fault in the sensor or related system.Q: How often should I replace my MAF or MAP sensor?

A: The lifespan of these sensors varies depending on factors such as driving conditions, maintenance practices, and the quality of the sensor itself. However, they generally last for several years.

Q: Can I clean my MAF or MAP sensor?

A: While cleaning a MAF sensor can sometimes improve its performance, it’s generally not recommended to clean a MAP sensor. If you suspect a sensor is dirty, consult a qualified mechanic for advice.

Tips for Maintaining Sensor Health

- Regular Maintenance: Follow the recommended maintenance schedule for your vehicle, including air filter replacement.

- Avoid Contaminating Sensors: Use caution when working on the engine to prevent dirt or debris from entering the MAF or MAP sensor.

- Professional Diagnosis: If you suspect a sensor malfunction, consult a qualified mechanic for diagnosis and repair.

Conclusion: A Vital Partnership for Engine Efficiency

The MAF and MAP sensors play distinct but complementary roles in the intricate process of engine control. Their accurate measurements of airflow and manifold pressure are essential for ensuring optimal combustion, efficient fuel consumption, and smooth engine performance. Recognizing the importance of these sensors, understanding their functions, and taking preventative measures to maintain their health are crucial for maximizing the longevity and efficiency of your vehicle.

Closure

Thus, we hope this article has provided valuable insights into Delving into the Differences: MAF and MAP Sensors in Automotive Systems. We appreciate your attention to our article. See you in our next article!