Delving into the Realm of High-Performance Tuning: Understanding the 4-Bar MAP Sensor

Related Articles: Delving into the Realm of High-Performance Tuning: Understanding the 4-Bar MAP Sensor

Introduction

With great pleasure, we will explore the intriguing topic related to Delving into the Realm of High-Performance Tuning: Understanding the 4-Bar MAP Sensor. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

Delving into the Realm of High-Performance Tuning: Understanding the 4-Bar MAP Sensor

The pursuit of optimal performance in internal combustion engines often leads enthusiasts and professionals alike to explore the realm of engine management systems. Within this domain, the manifold absolute pressure (MAP) sensor plays a crucial role, providing the engine control unit (ECU) with vital information regarding engine load. A standard 1-bar MAP sensor, however, may limit the potential for significant power gains in highly modified engines. This is where the 4-bar MAP sensor emerges as a potent tool for unlocking enhanced performance.

The Fundamental Role of a MAP Sensor:

A MAP sensor, essentially a pressure transducer, translates the pressure within the intake manifold into an electrical signal that the ECU interprets. This signal provides critical data about the engine’s load, influencing crucial parameters like fuel injection timing and duration, ignition timing, and boost control in turbocharged applications.

Why a 4-Bar MAP Sensor Stands Out:

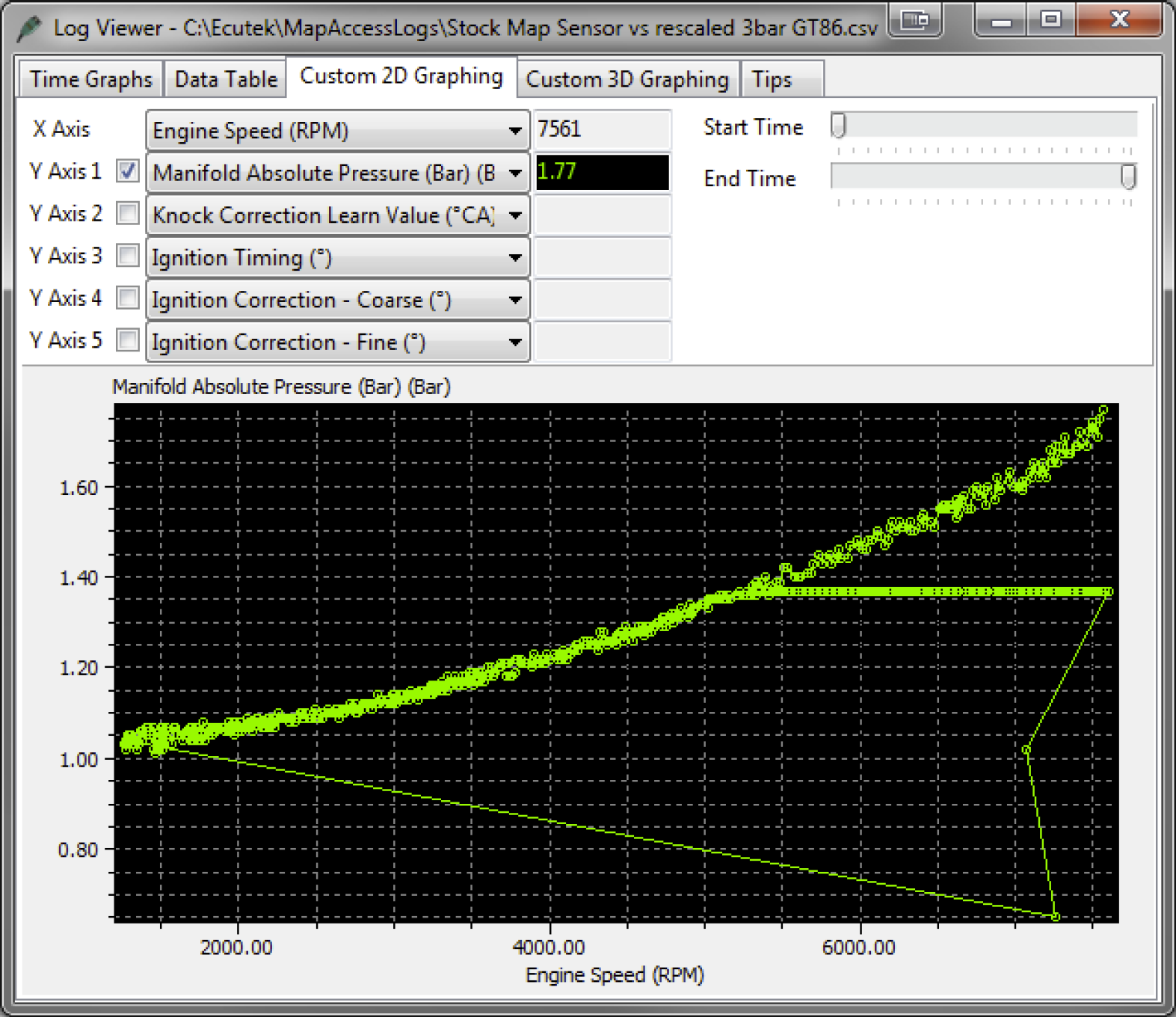

The standard 1-bar MAP sensor, designed for naturally aspirated engines, possesses a limited pressure range, typically up to 1 bar (14.5 psi). However, modified engines, particularly those equipped with turbochargers, can generate significantly higher boost pressures, exceeding the limitations of a 1-bar sensor. This is where the 4-bar MAP sensor comes into play, offering a wider pressure range (up to 4 bars or 58 psi) and allowing the ECU to accurately measure and respond to higher boost levels.

Benefits of Employing a 4-Bar MAP Sensor:

-

Enhanced Accuracy: By accurately measuring higher boost pressures, the 4-bar sensor provides the ECU with precise data, enabling it to optimize fuel and ignition timing for maximum performance.

-

Precise Boost Control: In turbocharged applications, the 4-bar sensor’s expanded pressure range allows for more precise boost control, ensuring consistent and optimal boost levels throughout the engine’s operating range.

-

Unleashing Power Potential: The accurate data provided by the 4-bar sensor empowers the ECU to effectively manage fuel and ignition timing, maximizing power output, particularly at higher boost levels.

-

Improved Throttle Response: The sensor’s ability to accurately measure changes in manifold pressure leads to quicker and more responsive throttle response, enhancing the driving experience.

Installation and Calibration:

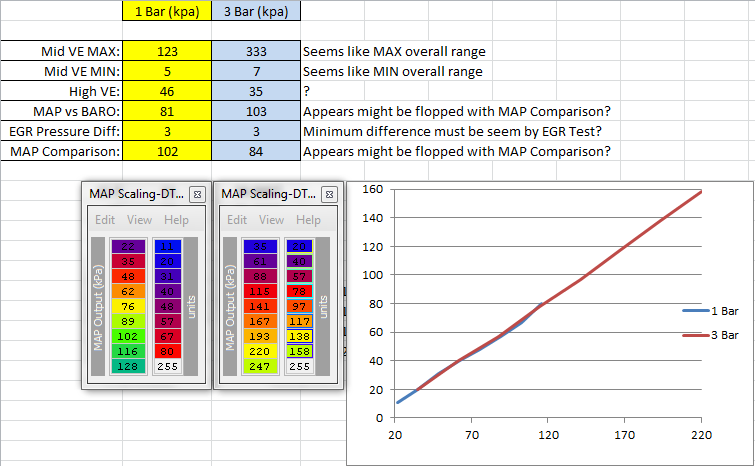

Installing a 4-bar MAP sensor typically involves replacing the existing 1-bar sensor. It is crucial to ensure that the sensor is properly wired and calibrated for optimal performance. Calibration involves adjusting the ECU’s settings to match the sensor’s pressure range and characteristics.

FAQs Regarding 4-Bar MAP Sensors:

Q: Is a 4-bar MAP sensor necessary for all modified engines?

A: While a 4-bar sensor is beneficial for high-boost applications, it may not be necessary for naturally aspirated engines or those with moderate boost levels. The need for a 4-bar sensor depends on the specific engine modifications and expected boost pressure.

Q: Can I use a 4-bar MAP sensor with a standard ECU?

A: Most modern ECUs can be reprogrammed to accommodate a 4-bar MAP sensor. However, older ECUs may not have the necessary functionality. It is essential to consult the ECU’s documentation or a professional tuner to determine compatibility.

Q: What are the potential drawbacks of using a 4-bar MAP sensor?

A: While generally beneficial, a 4-bar sensor may not be suitable for all applications. For example, in some cases, it might require modifications to the intake manifold or other engine components to accommodate the sensor’s larger size. Additionally, improper installation or calibration can lead to performance issues.

Tips for Utilizing a 4-Bar MAP Sensor:

-

Consult a Professional Tuner: It is highly recommended to consult a professional tuner to ensure proper installation, calibration, and optimization of the 4-bar sensor.

-

Choose a Reputable Brand: Opt for a high-quality 4-bar MAP sensor from a reputable manufacturer to ensure reliability and accuracy.

-

Ensure Compatibility: Verify that the sensor is compatible with your ECU and engine setup.

-

Proper Calibration: Calibration is crucial for optimal performance. Seek professional assistance for accurate calibration to match the sensor’s pressure range and engine characteristics.

Conclusion:

The 4-bar MAP sensor offers a significant advantage for those seeking to unlock the full potential of their modified engines, particularly in high-boost applications. By providing the ECU with precise pressure readings, it empowers the engine management system to optimize fuel and ignition timing, resulting in enhanced power, improved throttle response, and more efficient boost control. However, it is crucial to ensure proper installation, calibration, and compatibility to reap the full benefits of this powerful performance enhancement tool.

Closure

Thus, we hope this article has provided valuable insights into Delving into the Realm of High-Performance Tuning: Understanding the 4-Bar MAP Sensor. We appreciate your attention to our article. See you in our next article!