Maintaining Optimal Engine Performance: The Importance of a Clean Manifold Absolute Pressure (MAP) Sensor

Related Articles: Maintaining Optimal Engine Performance: The Importance of a Clean Manifold Absolute Pressure (MAP) Sensor

Introduction

With great pleasure, we will explore the intriguing topic related to Maintaining Optimal Engine Performance: The Importance of a Clean Manifold Absolute Pressure (MAP) Sensor. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

Maintaining Optimal Engine Performance: The Importance of a Clean Manifold Absolute Pressure (MAP) Sensor

The manifold absolute pressure (MAP) sensor plays a crucial role in ensuring efficient and reliable engine operation. This sensor, often located on the intake manifold, measures the pressure within the intake manifold, providing the engine control unit (ECU) with vital information for calculating engine load, fuel injection timing, and other critical parameters.

Over time, the MAP sensor can become contaminated with deposits from engine oil, fuel, or other contaminants. This buildup can affect the sensor’s ability to accurately measure manifold pressure, leading to a range of engine performance issues.

Understanding the Importance of a Clean MAP Sensor

A clean MAP sensor is essential for maintaining optimal engine performance. When the sensor is clean, it provides accurate pressure readings to the ECU, enabling it to:

- Calculate Precise Fuel Injection Timing: By accurately determining engine load, the ECU can optimize fuel injection timing, ensuring the correct amount of fuel is delivered at the optimal time for efficient combustion.

- Control Air-Fuel Ratio: The MAP sensor data is used to control the air-fuel ratio, ensuring an optimal mix for efficient combustion and minimizing emissions.

- Adjust Ignition Timing: The ECU utilizes MAP sensor data to adjust ignition timing, optimizing combustion efficiency and reducing engine knock.

- Monitor Engine Performance: A clean MAP sensor allows the ECU to monitor engine performance accurately, providing valuable data for diagnosing potential issues.

Signs of a Dirty or Faulty MAP Sensor

A malfunctioning MAP sensor can manifest in several ways, indicating the need for cleaning or replacement:

- Engine Hesitation or Stalling: A dirty sensor can lead to inaccurate pressure readings, causing the ECU to misinterpret engine load and deliver incorrect fuel injection timing, resulting in hesitation or stalling.

- Rough Idle: Similar to hesitation, a dirty MAP sensor can contribute to a rough idle as the ECU struggles to maintain the correct air-fuel ratio.

- Reduced Fuel Efficiency: An inaccurate air-fuel mixture due to a dirty sensor can lead to increased fuel consumption.

- Increased Emissions: A dirty MAP sensor can result in an imbalanced air-fuel mixture, leading to increased emissions and potential engine damage.

- Check Engine Light (CEL): A malfunctioning MAP sensor will often trigger the CEL, indicating a need for diagnosis and repair.

Cleaning the MAP Sensor: A Guide to Restoring Functionality

Cleaning a MAP sensor can be a relatively simple task, often requiring basic tools and materials. However, it’s crucial to follow the proper procedures to avoid damaging the sensitive sensor.

Materials Needed:

- Non-chlorinated brake cleaner: This solvent is effective at removing contaminants without damaging the sensor’s internal components.

- Clean rags or paper towels: For wiping away dirt and residue.

- Small brush or toothbrush: For gently cleaning the sensor’s exposed areas.

- Protective gloves: To prevent skin contact with the cleaning solution.

Cleaning Procedure:

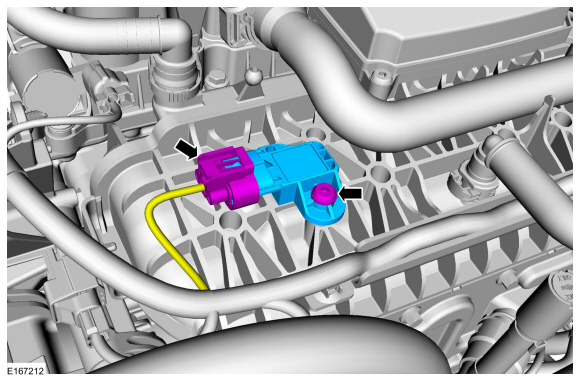

- Disconnect the MAP sensor connector: Locate the sensor on the intake manifold and disconnect the electrical connector.

- Remove the sensor: Carefully remove the sensor from its mounting location, noting its orientation for reinstallation.

- Clean the sensor: Using a clean rag or paper towel, gently wipe away any visible dirt or debris.

- Spray with brake cleaner: Carefully spray the sensor with non-chlorinated brake cleaner, focusing on the exposed sensing element. Avoid spraying directly into the electrical connector.

- Rinse with compressed air: After cleaning, use compressed air to remove any remaining residue.

- Dry thoroughly: Allow the sensor to air dry completely before reinstalling.

- Reinstall the sensor: Carefully reinstall the sensor in its original location, ensuring the electrical connector is securely connected.

Important Considerations:

- Avoid excessive force: When cleaning or reinstalling the sensor, use gentle pressure to prevent damage.

- Inspect for damage: Before cleaning, carefully inspect the sensor for any physical damage, such as cracks or broken wires. A damaged sensor may require replacement.

- Professional assistance: If you are uncomfortable performing this task or if the sensor shows signs of significant damage, consult a qualified mechanic for professional assistance.

FAQs: Addressing Common Questions about MAP Sensor Cleaning

1. Can I use other cleaning solutions besides brake cleaner?

While non-chlorinated brake cleaner is generally recommended, other solutions like carburetor cleaner or electronic contact cleaner can be used cautiously. Always check the product label for compatibility with plastic and rubber components.

2. How often should I clean my MAP sensor?

The frequency of cleaning depends on driving conditions and the type of fuel used. For vehicles operating in dusty or polluted environments or using low-quality fuel, cleaning may be necessary more frequently.

3. Can I clean the MAP sensor while it’s still connected to the vehicle?

It’s highly discouraged to clean the sensor while it’s connected to the vehicle. Disconnecting the sensor allows for thorough cleaning and prevents potential damage to the electrical components.

4. What if cleaning the sensor doesn’t resolve the engine problems?

If cleaning the sensor doesn’t resolve the engine issues, the sensor may be faulty and require replacement. Other potential causes should also be investigated, such as vacuum leaks, faulty fuel injectors, or ignition problems.

5. Can I use compressed air to blow out the sensor?

While compressed air can be used to remove residual cleaning solution, avoid blowing directly into the sensing element. The force of the air can damage the delicate sensor components.

Tips for Maintaining a Clean MAP Sensor

- Regularly inspect the sensor: Visually inspect the sensor for signs of dirt or debris during routine maintenance checks.

- Use high-quality fuel: Using high-quality fuel with additives can help minimize the buildup of contaminants.

- Change air filter regularly: A dirty air filter can allow contaminants to enter the intake manifold, potentially affecting the MAP sensor.

- Avoid idling for extended periods: Idling for long durations can increase the amount of oil vapor entering the intake manifold, contributing to sensor contamination.

Conclusion: Ensuring Long-Term Engine Health

A clean MAP sensor is essential for maintaining optimal engine performance, fuel efficiency, and emissions control. Regularly cleaning or replacing the sensor when necessary ensures accurate pressure readings, enabling the ECU to optimize engine operation. By following the guidelines outlined in this article, you can contribute to the long-term health and efficiency of your vehicle’s engine.

Closure

Thus, we hope this article has provided valuable insights into Maintaining Optimal Engine Performance: The Importance of a Clean Manifold Absolute Pressure (MAP) Sensor. We hope you find this article informative and beneficial. See you in our next article!