map sensor 6.7 cummins

Related Articles: map sensor 6.7 cummins

Introduction

With great pleasure, we will explore the intriguing topic related to map sensor 6.7 cummins. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

The Crucial Role of the Manifold Absolute Pressure Sensor in 6.7 Cummins Engines

The 6.7 Cummins engine, a powerhouse renowned for its durability and performance, relies on a sophisticated network of sensors to ensure optimal operation. Among these critical components is the Manifold Absolute Pressure (MAP) sensor, a seemingly unassuming device that plays a pivotal role in the engine’s control system. This article delves into the workings of the MAP sensor, exploring its significance, common issues, and effective troubleshooting strategies.

Understanding the MAP Sensor’s Function:

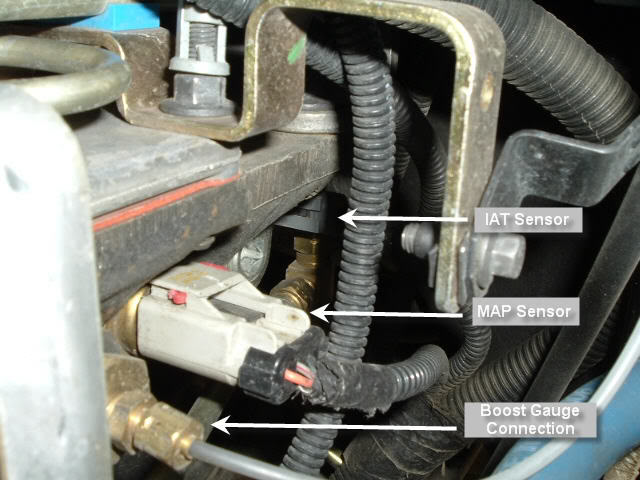

The MAP sensor is a key player in the engine’s electronic control unit (ECU) system. Its primary responsibility is to measure the absolute pressure within the engine’s intake manifold. This pressure, a direct reflection of the air density entering the cylinders, is crucial for the ECU to calculate the optimal fuel-air mixture for combustion.

Here’s a breakdown of the MAP sensor’s role in the engine’s intricate dance:

- Air-Fuel Ratio Control: The ECU uses the MAP sensor reading to determine the precise amount of fuel injected into the cylinders. This ensures an ideal air-fuel ratio, maximizing combustion efficiency and minimizing emissions.

- Boost Pressure Monitoring: In turbocharged engines, the MAP sensor also monitors the boost pressure generated by the turbocharger. This information enables the ECU to adjust fuel delivery and ignition timing to optimize performance and prevent damage from excessive boost.

- Engine Timing Adjustments: Based on the MAP sensor readings, the ECU can fine-tune the engine’s timing, ensuring optimal combustion and reducing harmful emissions.

The Importance of a Functioning MAP Sensor:

A faulty MAP sensor can have significant consequences for the engine’s performance and overall health. Here’s a glimpse into the potential issues:

- Engine Misfires: An inaccurate MAP sensor reading can lead to an incorrect air-fuel ratio, resulting in misfires and reduced engine power.

- Poor Fuel Economy: An imbalanced air-fuel mixture can significantly impact fuel consumption, leading to a noticeable drop in mileage.

- Increased Emissions: A malfunctioning MAP sensor can disrupt the engine’s timing and fuel delivery, resulting in increased emissions and potential engine damage.

- Check Engine Light: A faulty MAP sensor will trigger a check engine light, signaling a need for immediate attention.

Common MAP Sensor Issues and Troubleshooting:

While MAP sensors are generally robust, they can be prone to certain issues over time. Here are some common problems and troubleshooting steps:

- Contamination: Dust, dirt, or oil accumulation can affect the sensor’s accuracy. Cleaning the sensor with a suitable cleaner can often resolve the issue.

- Electrical Failures: A faulty wiring harness or connector can interrupt the sensor’s communication with the ECU. Inspecting the wiring and ensuring proper connections is crucial.

- Sensor Failure: Over time, the sensor itself can become faulty, requiring replacement. Testing the sensor with a multimeter or specialized diagnostic tool can confirm its failure.

Troubleshooting Strategies:

When encountering engine performance issues, a thorough inspection of the MAP sensor is essential. Here’s a step-by-step approach to troubleshooting:

- Visual Inspection: Begin by examining the sensor for signs of dirt, oil, or damage. Clean the sensor if necessary.

- Check Connections: Ensure the wiring harness and connectors are secure and free from corrosion.

- Test the Sensor: Utilize a multimeter or a diagnostic tool to test the sensor’s resistance and voltage readings. Compare the results to the manufacturer’s specifications.

- Clear Codes: If a check engine light is present, use a diagnostic tool to clear the codes and monitor for their return. This can help pinpoint the root cause of the issue.

- Replacement: If the sensor fails the test, replace it with a genuine OEM part.

FAQs Regarding the MAP Sensor:

Q: How often should the MAP sensor be replaced?

A: There’s no set schedule for MAP sensor replacement. However, it’s generally recommended to inspect and clean the sensor during routine maintenance, such as oil changes. If the sensor is showing signs of wear or failure, it should be replaced promptly.

Q: Can I use an aftermarket MAP sensor?

A: While aftermarket MAP sensors are available, it’s always recommended to use OEM parts for optimal performance and compatibility. Using a non-OEM sensor may lead to inaccurate readings and potential engine damage.

Q: What are the symptoms of a bad MAP sensor?

A: Symptoms of a failing MAP sensor include engine misfires, rough idling, decreased fuel economy, reduced power, and a check engine light.

Q: Can I drive with a faulty MAP sensor?

A: While driving with a faulty MAP sensor is possible, it’s not recommended. The engine may run poorly, and the issue could worsen over time, leading to more serious problems.

Tips for Maintaining the MAP Sensor:

- Regular Cleaning: Clean the sensor with a suitable cleaner during routine maintenance to prevent dirt and oil accumulation.

- Inspect Connections: Regularly check the wiring harness and connectors for signs of damage or corrosion.

- Use High-Quality Fuel: Using high-quality fuel can help prevent fuel system contamination that can affect the MAP sensor.

- Avoid Harsh Environments: Excessive dust, dirt, and extreme temperatures can damage the sensor.

Conclusion:

The MAP sensor plays a vital role in the 6.7 Cummins engine’s operation, ensuring optimal fuel-air mixture, boost pressure control, and engine timing. A functioning MAP sensor is crucial for smooth engine performance, fuel efficiency, and reduced emissions. Regular maintenance, proper troubleshooting, and prompt replacement of faulty sensors are essential to maintain the engine’s health and performance. By understanding the MAP sensor’s function and its potential issues, owners can ensure their 6.7 Cummins engine runs at peak efficiency for years to come.

Closure

Thus, we hope this article has provided valuable insights into map sensor 6.7 cummins. We thank you for taking the time to read this article. See you in our next article!