map sensor 7.3 powerstroke

Related Articles: map sensor 7.3 powerstroke

Introduction

With great pleasure, we will explore the intriguing topic related to map sensor 7.3 powerstroke. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

The Vital Role of the Manifold Absolute Pressure Sensor in the 7.3 Powerstroke Engine

The 7.3 Powerstroke engine, renowned for its robust performance and durability, relies on a complex interplay of sensors and actuators to deliver optimal power and efficiency. Among these crucial components, the Manifold Absolute Pressure (MAP) sensor plays a pivotal role in ensuring smooth and reliable engine operation. This article delves into the workings of the MAP sensor, its significance in the 7.3 Powerstroke engine, and common issues associated with its malfunction.

Understanding the MAP Sensor’s Function

The MAP sensor, a small electronic device typically mounted on the intake manifold, acts as the engine’s "pressure gauge." It measures the absolute pressure within the intake manifold, providing the engine control unit (ECU) with vital information about the engine’s load and air density. This information is critical for the ECU to accurately calculate fuel injection timing, fuel delivery volume, and other parameters that directly impact engine performance.

How the MAP Sensor Works

The MAP sensor operates on the principle of piezoresistive sensing. It contains a diaphragm that flexes in response to pressure changes within the intake manifold. This flexing alters the resistance of a piezoresistive element within the sensor, generating a corresponding electrical signal. The ECU interprets this signal, translating it into a pressure reading that reflects the engine’s load and air density.

The MAP Sensor’s Impact on Engine Performance

The MAP sensor’s role extends far beyond simply measuring pressure. Its accurate readings are crucial for:

- Precise Fuel Injection Timing: The ECU relies on MAP sensor data to determine the optimal timing for fuel injection, ensuring efficient combustion and maximizing power output.

- Accurate Fuel Delivery: The MAP sensor provides the ECU with information about the engine’s load and air density, allowing it to calculate the precise amount of fuel needed for each combustion cycle.

- Optimizing Air-Fuel Ratio: By accurately measuring manifold pressure, the MAP sensor enables the ECU to maintain the ideal air-fuel ratio for optimal combustion and emissions control.

- Smooth Engine Operation: The MAP sensor’s data contributes to a stable idle, smooth acceleration, and consistent power delivery across the engine’s operating range.

Common Issues with the MAP Sensor

Like any electronic component, the MAP sensor can be prone to failure. Common symptoms of a faulty MAP sensor include:

- Rough Idle: A malfunctioning MAP sensor can cause erratic idle speeds, leading to engine vibrations and stalling.

- Poor Acceleration: An inaccurate pressure reading can disrupt fuel delivery, resulting in sluggish acceleration and a lack of power.

- Increased Fuel Consumption: Incorrect fuel delivery due to a faulty MAP sensor can lead to inefficient combustion and increased fuel consumption.

- Check Engine Light: A faulty MAP sensor will trigger the Check Engine Light, often accompanied by diagnostic codes related to fuel system malfunctions.

Diagnosing and Replacing a Faulty MAP Sensor

Diagnosing a faulty MAP sensor typically involves a combination of:

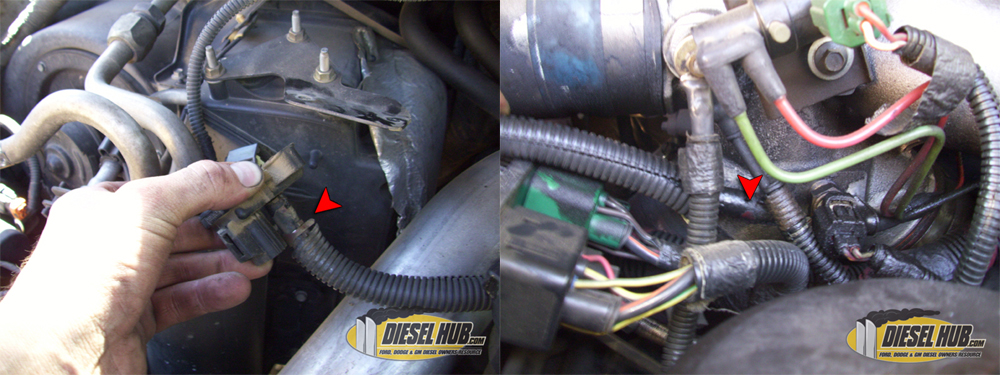

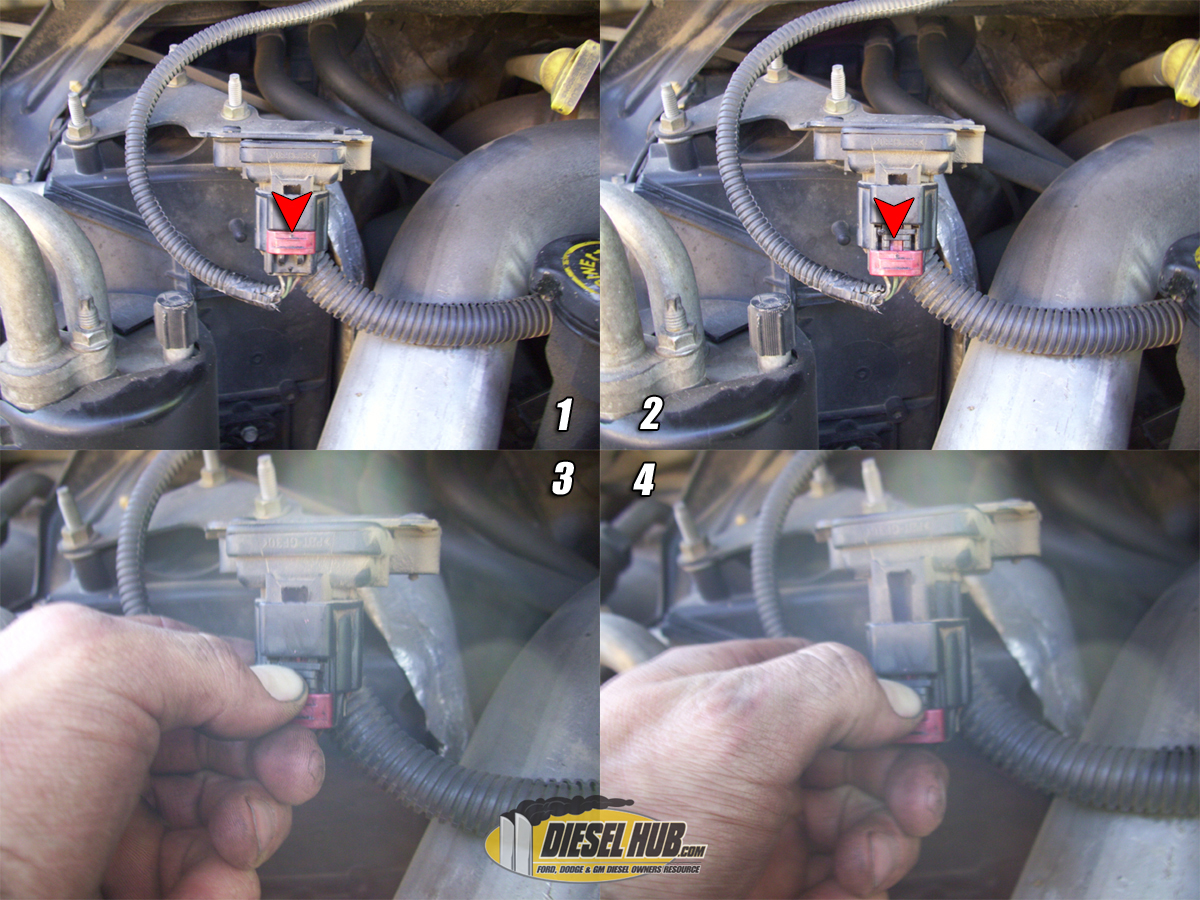

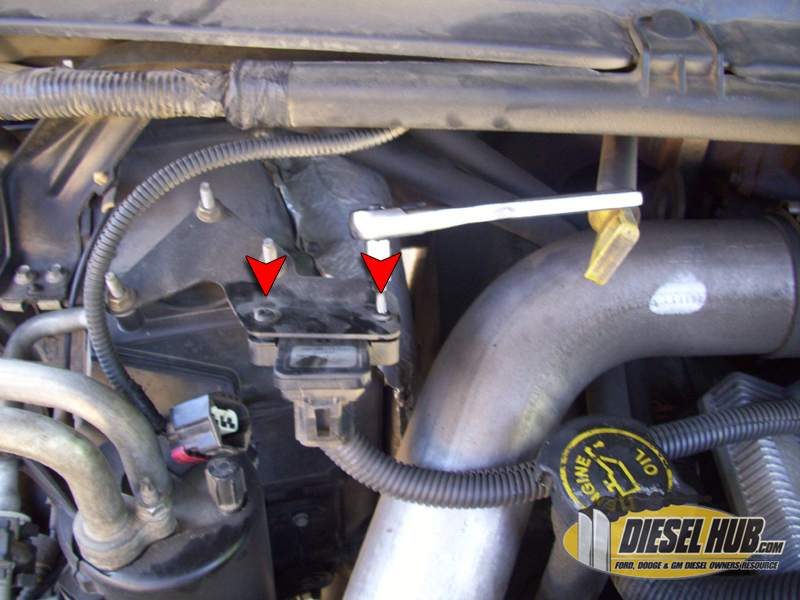

- Visual Inspection: Checking for any physical damage or corrosion on the sensor itself or its wiring.

- Diagnostic Code Analysis: Utilizing an OBD-II scanner to retrieve diagnostic codes that may point to a MAP sensor malfunction.

- Pressure Testing: Using a pressure gauge to compare the MAP sensor’s readings to actual manifold pressure.

If a faulty MAP sensor is identified, replacing it is a straightforward process. It involves disconnecting the sensor from its wiring harness, removing it from its mounting location, and installing a new sensor. The new sensor should be properly connected to the wiring harness and secured in its mounting location.

FAQs about the MAP Sensor

Q: Can a faulty MAP sensor cause a no-start condition?

A: While a faulty MAP sensor is unlikely to cause a complete no-start condition, it can significantly disrupt the engine’s starting process, making it difficult to start.

Q: How often should the MAP sensor be replaced?

A: The MAP sensor is generally a long-lasting component, but its lifespan can vary depending on environmental factors and engine usage. It is recommended to inspect the sensor regularly for signs of wear or damage.

Q: Can I clean a faulty MAP sensor?

A: Cleaning a faulty MAP sensor is generally not recommended. The sensor’s internal components are delicate and can be easily damaged by cleaning attempts. Replacing the sensor is the most reliable solution.

Q: Can a faulty MAP sensor affect emissions?

A: Yes, a faulty MAP sensor can disrupt the engine’s air-fuel ratio, leading to increased emissions and potentially failing emissions tests.

Tips for Maintaining the MAP Sensor

- Regular Inspection: Periodically inspect the MAP sensor for any signs of damage, corrosion, or loose connections.

- Cleanliness: Ensure the area around the MAP sensor is clean and free of debris that could obstruct its operation.

- Preventative Maintenance: Address any underlying engine issues that might lead to excessive pressure fluctuations or contaminants in the intake manifold, which can damage the MAP sensor.

Conclusion

The MAP sensor is an essential component in the 7.3 Powerstroke engine, playing a vital role in ensuring optimal performance, fuel efficiency, and emissions control. Understanding the sensor’s function, recognizing potential issues, and implementing proper maintenance practices are crucial for maximizing the engine’s lifespan and performance. By addressing any MAP sensor problems promptly, owners can ensure the smooth and reliable operation of their 7.3 Powerstroke engine.

Closure

Thus, we hope this article has provided valuable insights into map sensor 7.3 powerstroke. We thank you for taking the time to read this article. See you in our next article!