Navigating the Air: A Comprehensive Guide to MAP and MAF Sensors

Related Articles: Navigating the Air: A Comprehensive Guide to MAP and MAF Sensors

Introduction

In this auspicious occasion, we are delighted to delve into the intriguing topic related to Navigating the Air: A Comprehensive Guide to MAP and MAF Sensors. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

Navigating the Air: A Comprehensive Guide to MAP and MAF Sensors

The intricate dance of combustion within an internal combustion engine relies on a precise balance of fuel and air. This delicate choreography is orchestrated by various sensors, two of which play pivotal roles in determining the engine’s air intake: the Manifold Absolute Pressure (MAP) sensor and the Mass Air Flow (MAF) sensor. While both contribute to the smooth operation of the engine, they employ distinct methods to measure air intake, resulting in unique characteristics and applications.

Understanding the MAP Sensor: A Gauge of Pressure

The MAP sensor, a crucial component in older engine management systems, operates on the principle of measuring the pressure within the intake manifold. This pressure, directly proportional to the amount of air drawn into the engine, provides a valuable indicator of air density.

The sensor itself consists of a diaphragm, a pressure transducer, and a voltage output circuit. As air enters the manifold, it exerts pressure on the diaphragm, causing it to deflect. This deflection is translated into an electrical signal by the pressure transducer, which is then sent to the engine control unit (ECU).

Benefits of the MAP Sensor:

- Simplicity and Cost-Effectiveness: MAP sensors are relatively simple in design, making them less expensive to manufacture and maintain.

- Robustness: These sensors are generally more robust and less susceptible to damage compared to MAF sensors.

- Wide Operating Range: MAP sensors can accurately measure pressure over a broad range, making them suitable for engines operating under varying conditions.

Limitations of the MAP Sensor:

- Indirect Measurement: The MAP sensor does not directly measure air mass, relying on the pressure measurement to infer the volume of air entering the engine. This indirect measurement can be less accurate, especially at high engine speeds and under fluctuating conditions.

- Susceptibility to Vacuum Leaks: Vacuum leaks in the intake manifold can significantly affect the MAP sensor’s readings, leading to inaccurate air mass estimations.

Exploring the MAF Sensor: Weighing the Air

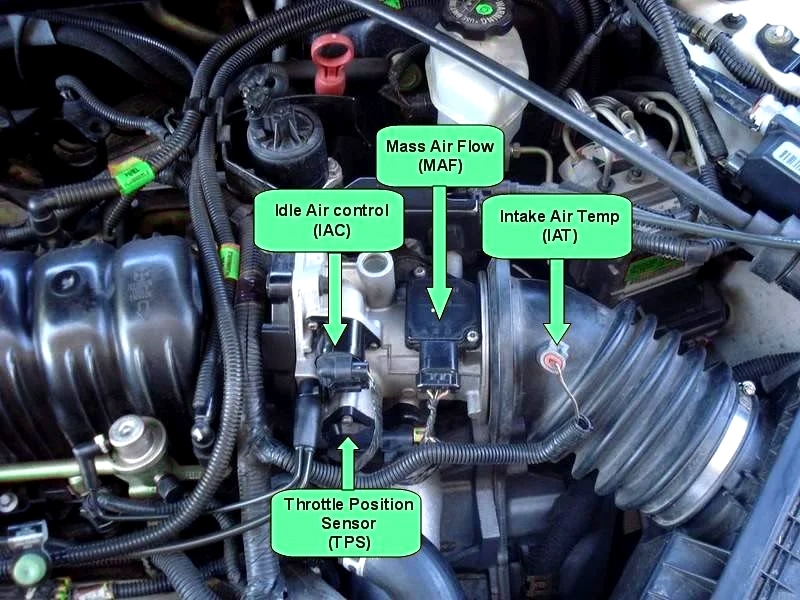

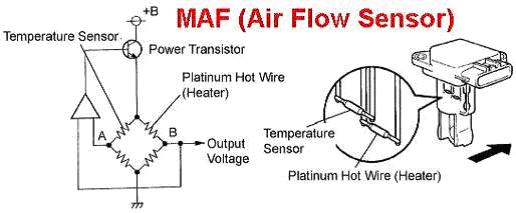

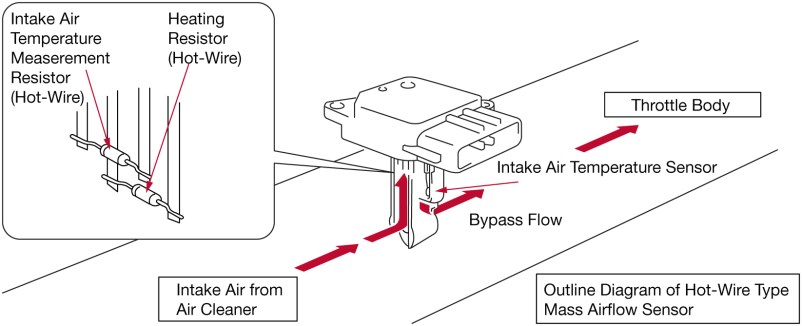

The MAF sensor, a more sophisticated technology often found in modern engine management systems, directly measures the mass of air entering the engine. It accomplishes this by utilizing a heated wire or hot film sensor that detects the change in resistance caused by the airflow.

As air passes over the heated wire, it cools the wire, changing its resistance. The ECU measures this resistance change, correlating it to the mass of air flowing through the sensor.

Benefits of the MAF Sensor:

- Direct Measurement: The MAF sensor directly measures air mass, providing a more precise and accurate reading compared to the MAP sensor.

- Enhanced Fuel Efficiency: Precise air mass measurement leads to more accurate fuel injection, resulting in optimized fuel consumption and reduced emissions.

- Improved Performance: Accurate air mass information enables the ECU to optimize engine timing and fuel delivery, leading to smoother engine operation and improved performance.

Limitations of the MAF Sensor:

- Complexity and Cost: MAF sensors are more complex and expensive to manufacture and maintain compared to MAP sensors.

- Sensitivity to Contamination: The heated wire or hot film sensor is sensitive to contamination from oil, dirt, or debris, which can significantly affect its accuracy.

- Limited Operating Range: MAF sensors typically have a narrower operating range compared to MAP sensors, making them less suitable for extreme conditions.

The Interplay of MAP and MAF Sensors: A Collaborative Approach

While the MAP and MAF sensors offer distinct advantages and disadvantages, they can also be used in conjunction, forming a synergistic approach to air mass measurement. This hybrid system, often found in modern engines, combines the robustness and wide operating range of the MAP sensor with the accuracy and precision of the MAF sensor.

In this scenario, the MAF sensor serves as the primary air mass measurement device, providing accurate readings under normal operating conditions. However, at high engine speeds or under extreme conditions, the MAP sensor takes over, ensuring reliable air mass information even when the MAF sensor’s performance is compromised.

FAQs: Decoding the Differences

Q: Which sensor is better, MAP or MAF?

A: The choice between MAP and MAF sensors depends on the specific application and the desired performance characteristics. MAF sensors offer greater accuracy and precision, while MAP sensors are more robust and cost-effective.

Q: Can I replace a MAP sensor with a MAF sensor?

A: Replacing a MAP sensor with a MAF sensor is generally not possible without significant modifications to the engine management system. The ECU is specifically designed to work with either a MAP or a MAF sensor, and a direct swap is unlikely to be compatible.

Q: How can I tell if my MAP or MAF sensor is faulty?

A: A faulty MAP or MAF sensor can manifest in various symptoms, including:

- Engine Stalling: A faulty sensor can disrupt the air-fuel mixture, leading to stalling, especially at idle.

- Rough Idle: An inaccurate air mass reading can cause rough idling and engine vibrations.

- Reduced Power: A faulty sensor can hinder engine performance, resulting in reduced power and acceleration.

- Increased Fuel Consumption: An inaccurate air mass reading can lead to fuel enrichment, resulting in increased fuel consumption.

- Check Engine Light: A malfunctioning sensor will often trigger the check engine light, accompanied by a diagnostic code.

Tips for Maintaining MAP and MAF Sensors:

- Regular Inspections: Regularly inspect the sensors for signs of damage, contamination, or loose connections.

- Cleanliness: Maintain a clean intake system to prevent debris from accumulating on the MAF sensor.

- Professional Diagnosis: If you suspect a sensor malfunction, consult a qualified mechanic for a professional diagnosis and repair.

Conclusion: Precision in Air Management

The MAP and MAF sensors play crucial roles in optimizing engine performance and fuel efficiency. While they employ distinct methods to measure air intake, both contribute to the precise air-fuel mixture required for efficient combustion. Understanding their unique characteristics and applications is essential for diagnosing and resolving engine issues, ensuring optimal performance and longevity. By embracing the benefits of each sensor and recognizing their limitations, we can navigate the complex world of air management and ensure the smooth operation of our internal combustion engines.

Closure

Thus, we hope this article has provided valuable insights into Navigating the Air: A Comprehensive Guide to MAP and MAF Sensors. We appreciate your attention to our article. See you in our next article!