Navigating the Engine’s Pulse: A Deep Dive into Intake Manifold Absolute Pressure Sensors

Related Articles: Navigating the Engine’s Pulse: A Deep Dive into Intake Manifold Absolute Pressure Sensors

Introduction

In this auspicious occasion, we are delighted to delve into the intriguing topic related to Navigating the Engine’s Pulse: A Deep Dive into Intake Manifold Absolute Pressure Sensors. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

Navigating the Engine’s Pulse: A Deep Dive into Intake Manifold Absolute Pressure Sensors

The internal combustion engine, a marvel of engineering, relies on a delicate balance of air and fuel to produce power. One of the key components facilitating this balance is the intake manifold absolute pressure (IMAP) sensor, an unsung hero quietly monitoring the engine’s vital signs. This article will explore the inner workings of the IMAP sensor, its critical role in engine management, and the implications of its proper functioning.

Unveiling the IMAP Sensor: A Silent Guardian of Engine Performance

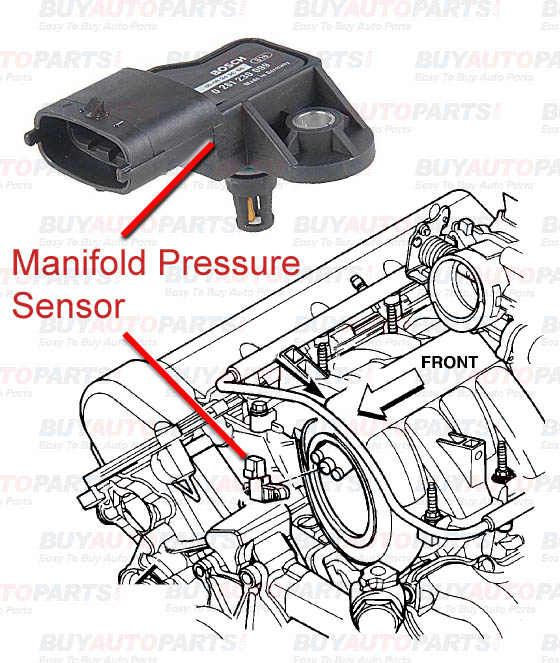

The IMAP sensor, also known as a manifold absolute pressure (MAP) sensor, acts as a vital link between the engine’s intake manifold and the engine control unit (ECU). It’s a small, robust device typically located within the intake manifold, often near the throttle body. Its primary function is to measure the absolute pressure within the intake manifold, providing the ECU with a crucial data point for precise engine control.

Understanding the IMAP Sensor’s Mechanism

The IMAP sensor operates on the principle of piezoresistive technology, leveraging the change in electrical resistance of a material under pressure. Inside the sensor, a diaphragm made of a piezoresistive material is exposed to the intake manifold pressure. As the pressure fluctuates, the diaphragm flexes, altering the electrical resistance. This change in resistance is then translated into a voltage signal, which is sent to the ECU.

Deciphering the Pressure Readings: A Window into Engine Health

The IMAP sensor’s voltage output directly corresponds to the absolute pressure within the intake manifold. This pressure, in turn, is a reflection of several critical engine parameters:

- Engine Load: Higher manifold pressure indicates a higher engine load, signifying more fuel being injected and more power being generated.

- Engine Speed: Higher engine speeds generally lead to higher manifold pressure, as the engine draws in more air.

- Air Density: Variations in air density due to factors like altitude or temperature changes affect manifold pressure.

- Engine Vacuum: During idle or low-load conditions, the intake manifold experiences a vacuum, which the IMAP sensor accurately measures.

The IMAP Sensor’s Influence: A Vital Contributor to Engine Control

The information provided by the IMAP sensor is vital for the ECU to make informed decisions regarding engine operation. Here’s how the sensor’s data influences engine control:

- Fuel Injection Timing and Quantity: The ECU uses the manifold pressure readings to determine the optimal timing and amount of fuel injection. This ensures the correct air-fuel ratio for efficient combustion and optimal power output.

- Ignition Timing: The IMAP sensor data influences ignition timing adjustments, maximizing combustion efficiency and minimizing emissions.

- Throttle Control: The ECU utilizes manifold pressure data to regulate throttle response, ensuring smooth acceleration and efficient power delivery.

- Engine Management System Adjustments: The IMAP sensor’s readings play a crucial role in adapting engine parameters to varying conditions like altitude, temperature, and load.

The Significance of a Functional IMAP Sensor: Avoiding Engine Malfunctions

A faulty IMAP sensor can lead to a cascade of problems, impacting engine performance and potentially causing damage. Here are some common issues associated with a malfunctioning IMAP sensor:

- Poor Fuel Economy: An inaccurate manifold pressure reading can result in improper fuel injection, leading to fuel wastage and reduced fuel efficiency.

- Engine Misfire: Incorrect fuel-air mixture due to faulty pressure readings can cause misfires, leading to rough engine operation and reduced power.

- Check Engine Light: A faulty IMAP sensor will trigger the check engine light, indicating a need for diagnostics and repairs.

- Reduced Power: Inaccurate manifold pressure readings can disrupt the engine’s ability to deliver optimal power, resulting in sluggish acceleration and reduced overall performance.

- Emissions Issues: A malfunctioning IMAP sensor can lead to increased emissions, impacting the environment and potentially failing emissions tests.

Diagnosing IMAP Sensor Issues: Identifying the Culprit

Identifying a faulty IMAP sensor requires careful diagnosis. Here are some common methods used by technicians:

- Visual Inspection: Checking the sensor for physical damage, corrosion, or loose connections.

- Resistance Test: Measuring the sensor’s resistance using a multimeter to verify its functionality.

- Voltage Test: Checking the sensor’s output voltage under different engine conditions using a scan tool.

- Engine Performance Evaluation: Observing engine symptoms like rough idle, misfires, or reduced power output.

- Diagnostic Scan Tool: Using a scan tool to retrieve diagnostic trouble codes (DTCs) related to the IMAP sensor.

Replacing a Faulty IMAP Sensor: Restoring Engine Health

Once a faulty IMAP sensor is identified, it’s crucial to replace it with a new, compatible sensor. Here’s a general guide for replacing an IMAP sensor:

- Disconnect the Battery: Ensure safety by disconnecting the vehicle’s battery before starting any work on the electrical system.

- Locate and Access the Sensor: Identify the IMAP sensor’s location, often near the intake manifold, and access it by removing surrounding components as necessary.

- Disconnect Electrical Connectors: Carefully disconnect the electrical connectors leading to the sensor, taking note of their orientation for reinstallation.

- Remove the Sensor: Unscrew or unclip the sensor from its mounting point, taking care not to damage surrounding components.

- Install the New Sensor: Insert the new IMAP sensor into its mounting point, ensuring it is securely fastened.

- Reconnect Electrical Connectors: Reconnect the electrical connectors to the new sensor, ensuring they are properly seated.

- Reconnect the Battery: Reconnect the battery and start the engine, observing for any error codes or abnormal engine operation.

FAQs: Addressing Common Concerns about the IMAP Sensor

Q: How often does an IMAP sensor need to be replaced?

A: IMAP sensors are typically designed to last the lifetime of the vehicle. However, factors like environmental conditions, engine wear, and improper maintenance can shorten their lifespan. If you experience symptoms related to a faulty IMAP sensor, it’s recommended to have it inspected and replaced if necessary.

Q: Can I replace an IMAP sensor myself?

A: Replacing an IMAP sensor can be a DIY project for some individuals with basic mechanical knowledge. However, it’s important to consult your vehicle’s owner’s manual for specific instructions and consider the complexity of the task before attempting it. If you’re unsure, it’s always best to consult a qualified mechanic.

Q: What are the signs of a faulty IMAP sensor?

A: Common signs include a check engine light, rough idle, misfires, reduced power, poor fuel economy, and difficulty starting the engine.

Q: Can a faulty IMAP sensor cause other engine problems?

A: Yes, a malfunctioning IMAP sensor can lead to a chain reaction of issues, potentially causing damage to other engine components if left unchecked. It’s crucial to address a faulty IMAP sensor promptly.

Tips for Maintaining Your IMAP Sensor

- Regular Maintenance: Adhering to regular maintenance schedules, including oil changes, air filter replacements, and engine tune-ups, helps prevent premature wear and tear on the IMAP sensor.

- Avoid Harsh Environments: Excessive exposure to extreme temperatures, dirt, and moisture can degrade the sensor’s performance.

- Inspect for Damage: Periodically inspect the IMAP sensor for signs of physical damage, corrosion, or loose connections.

- Use Quality Parts: When replacing the IMAP sensor, always use genuine or reputable aftermarket parts to ensure compatibility and reliability.

Conclusion: The IMAP Sensor’s Unsung Importance

The IMAP sensor, though often overlooked, plays a critical role in ensuring smooth and efficient engine operation. Its accurate pressure readings provide the ECU with vital data for precise fuel injection, ignition timing, and overall engine management. Recognizing the importance of a functional IMAP sensor and addressing any issues promptly can prevent performance degradation, emissions problems, and costly repairs. Maintaining this vital component helps ensure your vehicle’s longevity, fuel efficiency, and optimal performance.

.jpg)

Closure

Thus, we hope this article has provided valuable insights into Navigating the Engine’s Pulse: A Deep Dive into Intake Manifold Absolute Pressure Sensors. We hope you find this article informative and beneficial. See you in our next article!