The 2006 Mini Cooper S: Unveiling the Importance of the Manifold Absolute Pressure Sensor

Related Articles: The 2006 Mini Cooper S: Unveiling the Importance of the Manifold Absolute Pressure Sensor

Introduction

With great pleasure, we will explore the intriguing topic related to The 2006 Mini Cooper S: Unveiling the Importance of the Manifold Absolute Pressure Sensor. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

The 2006 Mini Cooper S: Unveiling the Importance of the Manifold Absolute Pressure Sensor

The 2006 Mini Cooper S, a celebrated model for its blend of sporty performance and compact design, relies on a sophisticated engine management system to deliver its signature driving experience. A crucial component within this system is the Manifold Absolute Pressure (MAP) sensor, a small but vital device that plays a critical role in the engine’s ability to breathe and function optimally.

Understanding the MAP Sensor’s Function

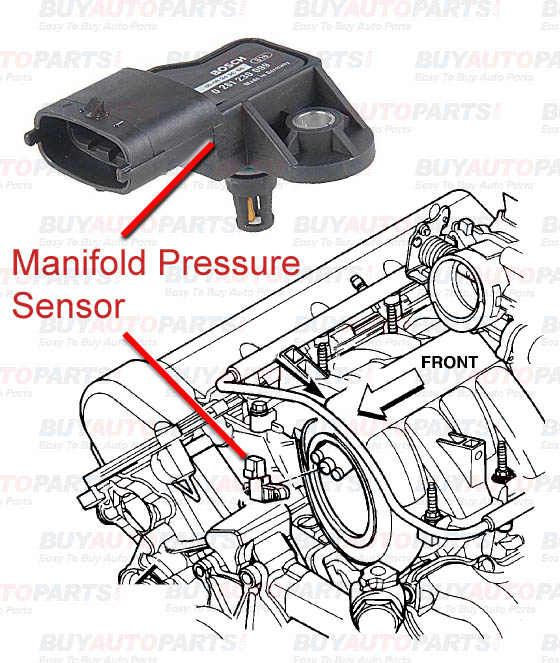

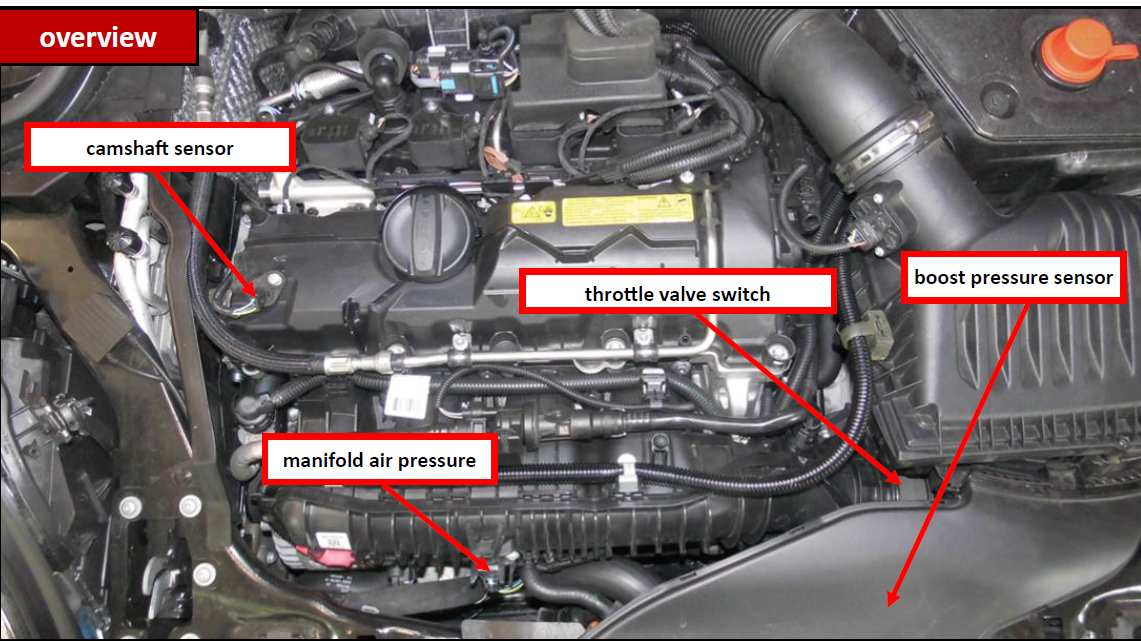

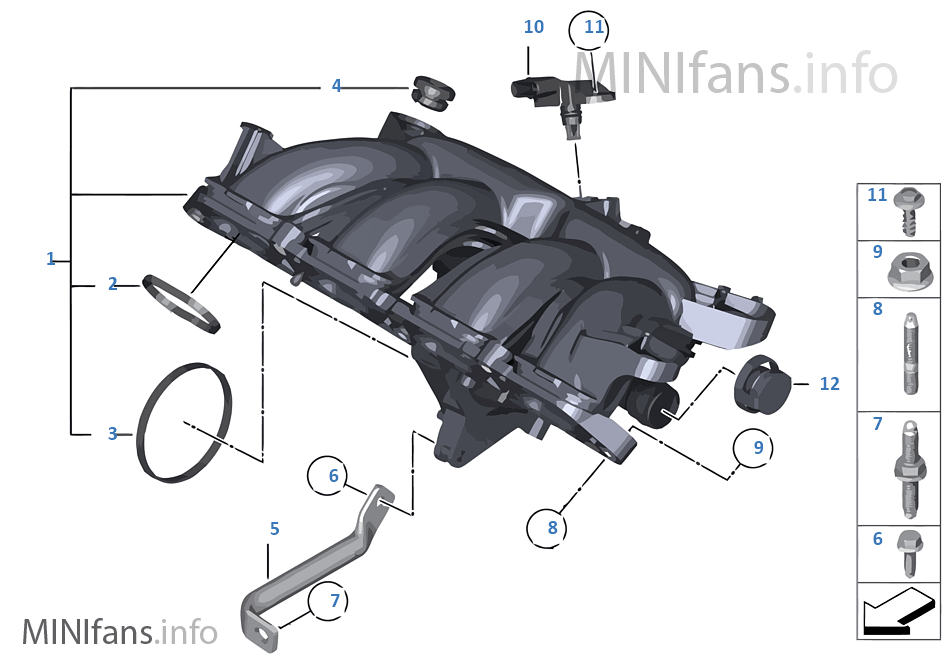

The MAP sensor, often referred to as a pressure sensor, is responsible for measuring the absolute pressure within the engine’s intake manifold. This pressure, which fluctuates depending on engine speed and load, provides the engine control unit (ECU) with crucial data about the air density entering the cylinders.

Imagine the intake manifold as the lungs of the engine. The MAP sensor acts as a barometer, measuring the air pressure within these "lungs" to inform the ECU about the amount of air being drawn in. This information is then used to calculate the precise amount of fuel needed for combustion, ensuring an ideal air-fuel mixture for optimal performance and fuel efficiency.

The Importance of Accurate Data

Accurate MAP sensor readings are paramount for the smooth operation of the 2006 Mini Cooper S engine. A malfunctioning sensor can lead to a range of problems, including:

- Poor Fuel Economy: An inaccurate reading can result in an overly rich or lean air-fuel mixture, leading to increased fuel consumption and reduced mileage.

- Reduced Engine Power: A lean mixture can cause misfires, resulting in a loss of power and sluggish acceleration. Conversely, a rich mixture can lead to excessive fuel consumption and potential damage to the catalytic converter.

- Rough Idle and Stalling: Inaccurate pressure readings can disrupt the delicate balance of the air-fuel mixture, causing the engine to idle erratically or even stall.

- Emission Problems: An imbalanced air-fuel mixture can result in increased emissions, potentially leading to failure of emissions tests.

- Check Engine Light: A faulty MAP sensor will often trigger a check engine light, prompting a diagnostic code that indicates a problem with the sensor.

Common Symptoms of a Failing MAP Sensor

While a check engine light is a clear indication of a potential problem, other symptoms can signal a failing MAP sensor:

- Loss of Power: Sudden or gradual decreases in engine power, especially during acceleration.

- Rough Idle: Unstable idling, with the engine shaking or vibrating.

- Stalling: The engine unexpectedly shutting off, particularly at low speeds or idle.

- Backfiring: Loud popping sounds from the exhaust, especially during acceleration or deceleration.

- Increased Fuel Consumption: Noticing a significant decrease in fuel efficiency.

Diagnosis and Replacement

If you suspect a faulty MAP sensor, it’s essential to have it diagnosed by a qualified mechanic. They will use a diagnostic scanner to read engine codes and assess the sensor’s functionality. If the sensor is determined to be faulty, it will need to be replaced.

Tips for Maintaining the MAP Sensor

While the MAP sensor is a relatively robust component, proper maintenance can help extend its lifespan:

- Regular Engine Tune-Ups: Ensure your engine is properly tuned, as a faulty ignition system or other engine problems can put additional stress on the sensor.

- Avoid Excessive Engine Modifications: Significant modifications to the intake system or engine can affect the sensor’s performance and may require adjustments to its calibration.

- Regular Inspections: Have the MAP sensor inspected during routine maintenance checks to ensure it is free of dirt, debris, or damage.

Frequently Asked Questions about the MAP Sensor

Q: How often does a MAP sensor need to be replaced?

A: The lifespan of a MAP sensor varies depending on driving conditions and maintenance practices. However, they typically last between 50,000 and 100,000 miles.

Q: Can I replace the MAP sensor myself?

A: While replacing the sensor is a relatively straightforward process, it’s recommended to have it done by a qualified mechanic. Improper installation can damage the sensor or other components.

Q: How can I prevent my MAP sensor from failing prematurely?

A: Regular engine maintenance, including tune-ups and inspections, can help extend the sensor’s life. Avoid excessive engine modifications and ensure the intake system is clean and free of debris.

Conclusion

The MAP sensor is an essential component in the 2006 Mini Cooper S engine management system, playing a critical role in delivering optimal performance and fuel efficiency. While the sensor is generally reliable, it’s crucial to be aware of its function and potential issues. Regular maintenance, early detection of symptoms, and prompt diagnosis and replacement are essential for ensuring a smooth and enjoyable driving experience in your Mini Cooper S.

Closure

Thus, we hope this article has provided valuable insights into The 2006 Mini Cooper S: Unveiling the Importance of the Manifold Absolute Pressure Sensor. We appreciate your attention to our article. See you in our next article!