The AEM 7 Bar MAP Sensor: A Key Component for High-Performance Engines

Related Articles: The AEM 7 Bar MAP Sensor: A Key Component for High-Performance Engines

Introduction

In this auspicious occasion, we are delighted to delve into the intriguing topic related to The AEM 7 Bar MAP Sensor: A Key Component for High-Performance Engines. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

The AEM 7 Bar MAP Sensor: A Key Component for High-Performance Engines

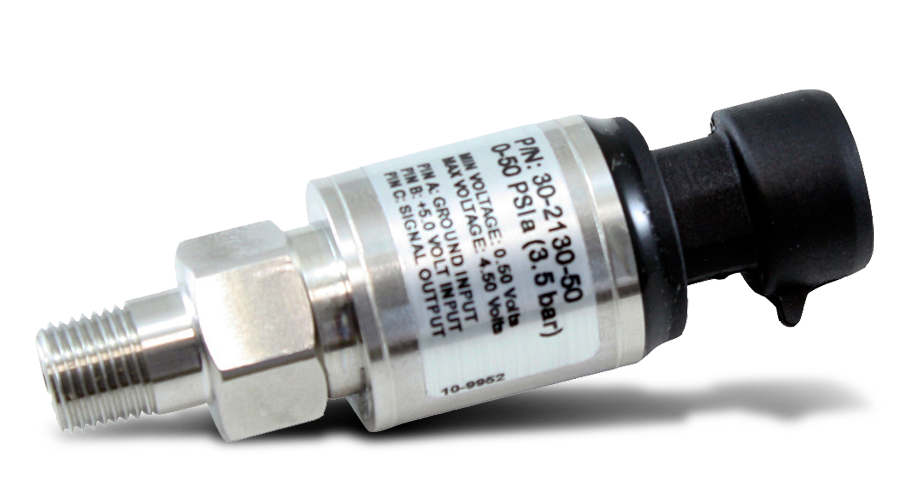

The AEM 7 Bar MAP (Manifold Absolute Pressure) sensor is a critical component in modern high-performance engines, particularly those utilizing forced induction systems like turbochargers or superchargers. It plays a vital role in accurately measuring the pressure within the engine’s intake manifold, providing crucial data for the engine control unit (ECU) to optimize fuel delivery, ignition timing, and boost control.

Understanding the Role of a MAP Sensor

The MAP sensor, in essence, acts as a pressure transducer. It converts the pressure within the intake manifold into an electrical signal that the ECU can interpret. This signal, representing the manifold absolute pressure (MAP), is a key parameter in determining the engine’s load and air density.

Why 7 Bar?

The "7 Bar" designation refers to the sensor’s maximum pressure measurement range. This range, equivalent to approximately 102 psi, is significantly higher than standard MAP sensors found in naturally aspirated engines. This high pressure range is essential for forced induction applications, where boost pressures can easily exceed the capabilities of conventional sensors.

Benefits of the AEM 7 Bar MAP Sensor

The AEM 7 Bar MAP sensor offers several advantages over standard sensors, making it a preferred choice for performance enthusiasts and tuners:

-

Enhanced Accuracy: The sensor’s high-precision design ensures accurate pressure readings even under extreme boost conditions, crucial for optimal engine performance and tuning.

-

Wider Pressure Range: The extended 7 Bar pressure range accommodates even the highest boost levels, allowing for greater tuning flexibility and power potential.

-

Improved Durability: The sensor is designed to withstand the harsh environment of high-performance engines, including extreme temperatures and vibrations.

-

Compatibility: The AEM 7 Bar MAP sensor is compatible with a wide range of aftermarket ECUs and engine management systems, providing flexibility for tuning and customization.

How the AEM 7 Bar MAP Sensor Works

The sensor operates on the principle of piezoresistive technology. A small, silicon diaphragm within the sensor is exposed to the intake manifold pressure. This pressure causes the diaphragm to flex, which in turn changes the resistance of a piezoresistive element. The ECU interprets these resistance changes as a voltage signal, directly proportional to the manifold pressure.

Applications of the AEM 7 Bar MAP Sensor

The AEM 7 Bar MAP sensor is widely used in various applications, including:

-

High-performance street cars: Enthusiasts seeking to extract maximum power and performance from their modified vehicles often opt for this sensor to accurately measure and control boost pressures.

-

Racing cars: The sensor’s accuracy and durability are crucial for professional racing applications, where precise engine control is paramount for optimal performance and reliability.

-

Off-road vehicles: The sensor’s ability to handle extreme conditions makes it suitable for off-road vehicles, where fluctuating pressures and harsh environments are common.

FAQs about the AEM 7 Bar MAP Sensor

Q: What are the common signs of a faulty MAP sensor?

A: A faulty MAP sensor can manifest in several ways, including:

- Rough idle: The engine may idle erratically or stall due to incorrect air/fuel mixture readings.

- Reduced power: The engine may experience a noticeable loss of power, especially under acceleration.

- Check engine light: The ECU may trigger a check engine light if it detects an error in the MAP sensor signal.

- Boost leaks: The engine may exhibit symptoms of boost leaks, such as inconsistent boost pressure or a hissing sound from the intake manifold.

Q: How do I calibrate the AEM 7 Bar MAP sensor?

A: The calibration process for the AEM 7 Bar MAP sensor is typically handled within the ECU’s software. This involves configuring the sensor’s scaling and offset values to match the specific application and tuning parameters. It is essential to follow the manufacturer’s instructions and consult with a qualified tuner for proper calibration.

Q: Is the AEM 7 Bar MAP sensor compatible with all ECUs?

A: While the AEM 7 Bar MAP sensor is compatible with a wide range of ECUs, it’s important to verify compatibility with your specific ECU before purchasing. Some ECUs may require specific wiring or programming configurations for proper operation.

Tips for Using the AEM 7 Bar MAP Sensor

- Proper installation: Ensure the sensor is securely mounted in a location that provides accurate pressure readings and is free from potential damage.

- Accurate wiring: Connect the sensor to the ECU using the appropriate wiring and connectors, adhering to the manufacturer’s instructions.

- Calibration: Proper calibration is essential for optimal performance. Consult with a qualified tuner for professional calibration services.

- Regular maintenance: Inspect the sensor for any signs of damage or wear. Replace the sensor if necessary to maintain accurate readings and engine performance.

Conclusion

The AEM 7 Bar MAP sensor is an essential component for high-performance engines, offering enhanced accuracy, wider pressure range, and improved durability compared to standard MAP sensors. Its ability to accurately measure and transmit pressure data to the ECU is crucial for optimizing fuel delivery, ignition timing, and boost control, leading to increased power, performance, and overall engine efficiency. By understanding the sensor’s role, benefits, and applications, enthusiasts and tuners can leverage its capabilities to unlock the full potential of their high-performance engines.

Closure

Thus, we hope this article has provided valuable insights into The AEM 7 Bar MAP Sensor: A Key Component for High-Performance Engines. We appreciate your attention to our article. See you in our next article!