The Air Intake Duo: Understanding the Roles of MAF and MAP Sensors in Engine Management

Related Articles: The Air Intake Duo: Understanding the Roles of MAF and MAP Sensors in Engine Management

Introduction

With enthusiasm, let’s navigate through the intriguing topic related to The Air Intake Duo: Understanding the Roles of MAF and MAP Sensors in Engine Management. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

The Air Intake Duo: Understanding the Roles of MAF and MAP Sensors in Engine Management

Modern internal combustion engines rely on sophisticated electronic control systems to optimize performance and efficiency. Two key components within these systems, the Mass Air Flow (MAF) sensor and the Manifold Absolute Pressure (MAP) sensor, play crucial roles in determining the precise amount of air entering the engine. While both sensors contribute to the engine’s air intake measurement, they operate on distinct principles and serve different purposes. Understanding the differences between these sensors is essential for comprehending how engines manage air intake and ultimately achieve optimal fuel delivery and combustion.

MAF Sensor: Weighing the Air

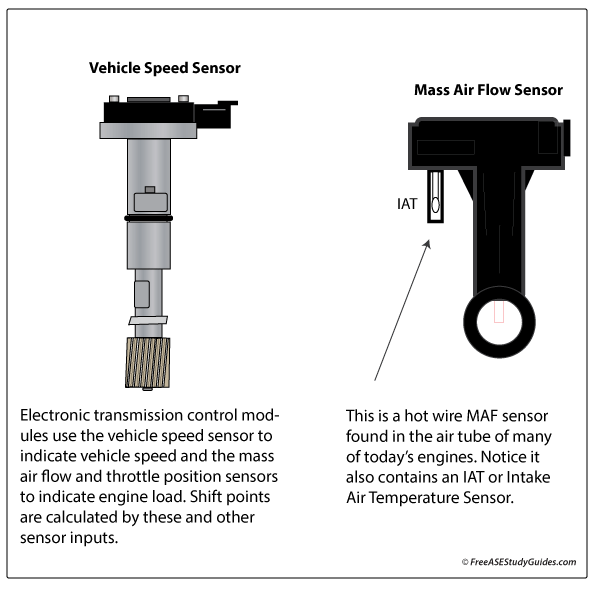

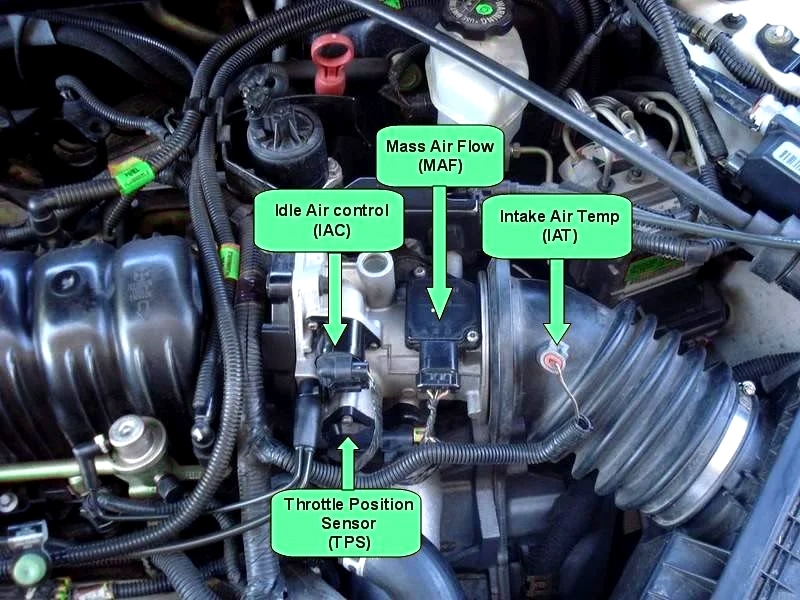

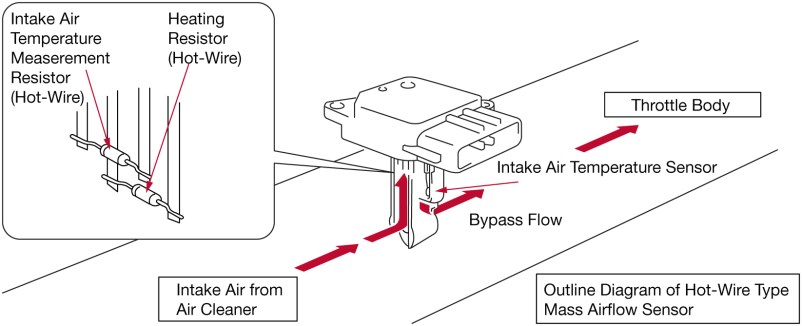

The Mass Air Flow (MAF) sensor is a crucial component in modern engine management systems, directly measuring the mass of air entering the engine. This information is vital for the engine control unit (ECU) to calculate the precise amount of fuel needed for combustion. The MAF sensor typically resides in the intake manifold, positioned directly after the air filter.

How MAF Sensors Work:

MAF sensors employ various technologies to measure air mass. A common approach utilizes a heated wire or a thin film sensor. The heated wire method involves a precisely heated wire placed within the airflow path. As air passes over the wire, it cools, and the change in resistance is measured. This change in resistance directly correlates to the mass of air flowing through the sensor. The thin film sensor operates similarly, relying on a thin film heated by a small current. The change in resistance due to air cooling provides a measure of air mass.

Advantages of MAF Sensors:

- Precise Air Mass Measurement: MAF sensors provide a direct and accurate measurement of the air mass entering the engine, leading to precise fuel delivery and optimal combustion.

- Real-Time Monitoring: MAF sensors offer real-time data on air flow, allowing the ECU to adjust fuel delivery dynamically based on changing engine conditions.

- Wide Range of Operation: MAF sensors can accurately measure air flow across a wide range of engine operating conditions, from idle to high RPM.

Limitations of MAF Sensors:

- Sensitivity to Contamination: MAF sensors are sensitive to contamination from dirt, oil, or other debris. Contamination can affect the sensor’s accuracy and lead to engine performance issues.

- Limited Operating Range: MAF sensors can struggle to accurately measure very low or very high airflow rates, potentially leading to inaccurate fuel delivery in extreme conditions.

MAP Sensor: Gauging the Pressure

The Manifold Absolute Pressure (MAP) sensor, unlike the MAF sensor, measures the pressure within the engine’s intake manifold. This pressure provides an indirect measure of the air mass entering the engine. MAP sensors are typically mounted on the intake manifold and connected to the ECU.

How MAP Sensors Work:

MAP sensors utilize a pressure transducer, a device that converts pressure into an electrical signal. The sensor measures the absolute pressure within the intake manifold, which is the pressure relative to a perfect vacuum. This pressure reading is then transmitted to the ECU, where it is used to calculate the air mass entering the engine.

Advantages of MAP Sensors:

- Robustness: MAP sensors are generally less susceptible to contamination compared to MAF sensors, making them more robust in harsh environments.

- Wide Operating Range: MAP sensors can accurately measure pressure across a wide range of engine operating conditions, including very low and very high airflow rates.

- Simpler Design: MAP sensors have a simpler design compared to MAF sensors, making them less expensive to manufacture.

Limitations of MAP Sensors:

- Indirect Air Mass Measurement: MAP sensors measure pressure, which is an indirect indicator of air mass. This can lead to less precise fuel delivery compared to MAF sensors.

- Sensitivity to Vacuum Leaks: Vacuum leaks in the intake manifold can affect the MAP sensor’s readings, leading to inaccurate air mass calculations and engine performance issues.

MAF vs. MAP: A Comparative Overview

| Feature | MAF Sensor | MAP Sensor |

|---|---|---|

| Measurement | Air mass | Manifold pressure |

| Accuracy | More accurate | Less accurate |

| Sensitivity to Contamination | More sensitive | Less sensitive |

| Operating Range | Limited | Wide |

| Cost | More expensive | Less expensive |

The Choice Between MAF and MAP: A Balancing Act

The choice between a MAF sensor and a MAP sensor depends on various factors, including engine design, operating conditions, and cost considerations. In general, MAF sensors are preferred in modern engines due to their ability to provide more accurate air mass measurements, leading to better fuel economy and emissions control. However, MAP sensors can be a suitable alternative in certain applications, such as engines operating in harsh environments or where cost is a significant concern.

Applications of MAF and MAP Sensors

- MAF Sensors: MAF sensors are commonly found in modern gasoline and diesel engines, particularly in passenger vehicles and light trucks. Their ability to provide accurate air mass measurements is crucial for optimizing fuel delivery and reducing emissions.

- MAP Sensors: MAP sensors are frequently used in older vehicles and in applications where cost or robustness is a priority. They are also employed in some turbocharged engines, where the pressure within the intake manifold can vary significantly.

FAQs: Unraveling the Mysteries of MAF and MAP Sensors

Q: What are the symptoms of a faulty MAF sensor?

A: A faulty MAF sensor can manifest in various symptoms, including:

- Rough idling: The engine may idle roughly or stall.

- Poor acceleration: The engine may hesitate or lack power during acceleration.

- Increased fuel consumption: The engine may consume more fuel than usual.

- Check engine light: The check engine light may illuminate, indicating a fault in the MAF sensor.

Q: What are the symptoms of a faulty MAP sensor?

A: A faulty MAP sensor can lead to similar symptoms as a faulty MAF sensor, including:

- Rough idling: The engine may idle roughly or stall.

- Poor acceleration: The engine may hesitate or lack power during acceleration.

- Increased fuel consumption: The engine may consume more fuel than usual.

- Check engine light: The check engine light may illuminate, indicating a fault in the MAP sensor.

Q: Can I clean a MAF sensor?

A: It is generally not recommended to clean a MAF sensor yourself. The sensor is very delicate, and cleaning it incorrectly can damage it. If you suspect a problem with your MAF sensor, it is best to have it inspected and cleaned by a qualified mechanic.

Q: Can I clean a MAP sensor?

A: MAP sensors are generally more robust than MAF sensors and can be cleaned with a mild cleaner, such as brake cleaner. However, it is important to avoid using harsh chemicals or excessive pressure, as this can damage the sensor.

Q: Can I replace a MAF sensor myself?

A: Replacing a MAF sensor is a relatively straightforward task for experienced DIYers. However, it is important to ensure that you have the correct replacement part and that you follow the manufacturer’s instructions carefully. If you are unsure about the process, it is best to consult a qualified mechanic.

Q: Can I replace a MAP sensor myself?

A: Replacing a MAP sensor is typically easier than replacing a MAF sensor, as it involves disconnecting the sensor and plugging in the new one. However, it is still important to ensure that you have the correct replacement part and that you follow the manufacturer’s instructions carefully.

Tips for Maintaining MAF and MAP Sensors

- Regular Air Filter Replacement: Regularly replacing the air filter helps prevent dirt and debris from entering the intake manifold and contaminating the MAF sensor.

- Avoid Over-Oiling Air Filters: Excessive oil on the air filter can contaminate the MAF sensor.

- Avoid Using Harsh Chemicals: Avoid using harsh chemicals or solvents near the MAF or MAP sensors, as this can damage them.

- Professional Inspection and Cleaning: If you suspect a problem with your MAF or MAP sensor, have it inspected and cleaned by a qualified mechanic.

Conclusion: The Unsung Heroes of Engine Management

While often overlooked, the MAF and MAP sensors play vital roles in ensuring optimal engine performance and efficiency. Understanding their functions and differences is crucial for diagnosing engine issues and maintaining peak performance. By ensuring the proper operation of these sensors, you can contribute to a smoother, more efficient, and environmentally friendly driving experience. As technology advances, these sensors will continue to play a crucial role in the evolution of engine management systems, paving the way for even greater efficiency and performance.

Closure

Thus, we hope this article has provided valuable insights into The Air Intake Duo: Understanding the Roles of MAF and MAP Sensors in Engine Management. We appreciate your attention to our article. See you in our next article!