The Air Intake Guardians: Exploring the Roles of MAP and MAF Sensors in Modern Engines

Related Articles: The Air Intake Guardians: Exploring the Roles of MAP and MAF Sensors in Modern Engines

Introduction

With enthusiasm, let’s navigate through the intriguing topic related to The Air Intake Guardians: Exploring the Roles of MAP and MAF Sensors in Modern Engines. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

The Air Intake Guardians: Exploring the Roles of MAP and MAF Sensors in Modern Engines

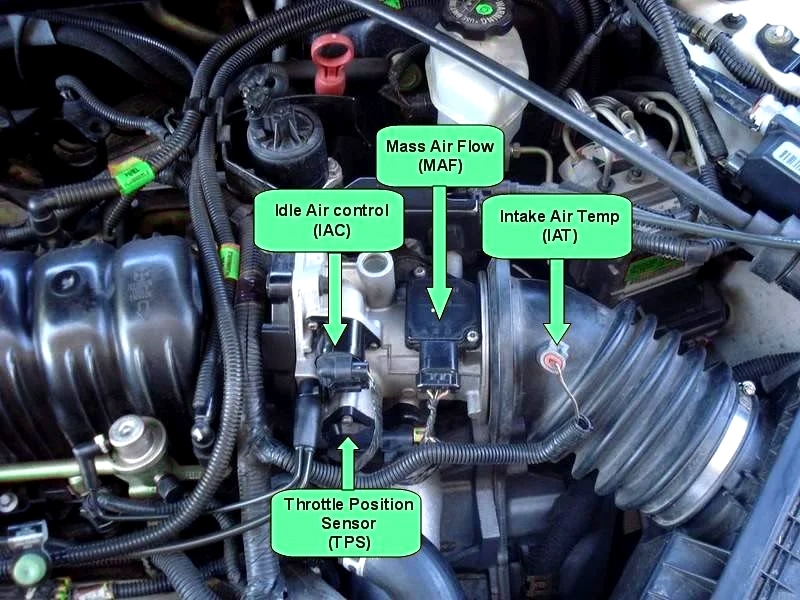

Modern internal combustion engines rely on precise air-fuel ratios for optimal performance and emissions control. Two crucial sensors, the Manifold Absolute Pressure (MAP) sensor and the Mass Air Flow (MAF) sensor, play pivotal roles in determining the amount of air entering the engine. While both sensors share the common goal of measuring airflow, their methods and applications differ significantly. Understanding these differences is essential for comprehending how modern engines operate and troubleshoot potential issues.

The MAP Sensor: A Measure of Pressure

The MAP sensor, a critical component in engine management systems, measures the absolute pressure within the intake manifold. This pressure, a reflection of the amount of air present in the manifold, serves as a proxy for the air mass entering the engine.

How the MAP Sensor Works:

The MAP sensor is typically a piezoresistive device. It consists of a diaphragm that flexes under pressure, altering the resistance of a semiconductor material. This change in resistance is then translated into a voltage signal, which the engine control unit (ECU) interprets as a measure of manifold pressure.

Applications of the MAP Sensor:

MAP sensors are commonly found in naturally aspirated engines, where the intake manifold pressure is directly related to the amount of air drawn in by the engine. The ECU utilizes this information to calculate the appropriate amount of fuel to inject, ensuring an optimal air-fuel ratio for combustion.

Advantages of the MAP Sensor:

- Simplicity and Cost-Effectiveness: MAP sensors are relatively simple and inexpensive to manufacture, making them a cost-effective solution for many engine applications.

- Durability: MAP sensors are typically robust and can withstand harsh engine environments.

Limitations of the MAP Sensor:

- Limited Accuracy at High Airflow: MAP sensors struggle to accurately measure airflow at high engine speeds or under boost conditions, where pressure fluctuations become more significant.

- Susceptible to Vacuum Leaks: A leak in the intake manifold can significantly affect the accuracy of the MAP sensor, leading to incorrect fuel delivery and engine performance issues.

The MAF Sensor: Weighing the Air

In contrast to the MAP sensor, the MAF sensor directly measures the mass of air entering the engine. This measurement is crucial for accurate fuel metering, especially in turbocharged and supercharged engines where pressure fluctuations are more pronounced.

How the MAF Sensor Works:

MAF sensors utilize a variety of technologies, with the most common being the hot-wire and hot-film designs. These sensors contain a heated element that is exposed to the incoming air stream. As air flows past the element, it cools down, altering its resistance. The ECU measures this resistance change to determine the airflow rate.

Applications of the MAF Sensor:

MAF sensors are typically used in engines equipped with turbochargers or superchargers, where the intake manifold pressure can vary significantly. The MAF sensor provides a more precise measurement of airflow, enabling the ECU to accurately control fuel delivery under these dynamic conditions.

Advantages of the MAF Sensor:

- Accurate Airflow Measurement: MAF sensors provide a more precise measurement of airflow compared to MAP sensors, particularly at high engine speeds and under boost conditions.

- Improved Fuel Economy and Emissions: Accurate airflow measurement leads to optimized fuel delivery, improving fuel efficiency and reducing emissions.

Limitations of the MAF Sensor:

- Cost and Complexity: MAF sensors are generally more complex and expensive to manufacture than MAP sensors.

- Sensitivity to Contaminants: MAF sensors can be sensitive to contaminants in the air stream, such as dirt, oil, or water, which can affect their accuracy and performance.

Choosing the Right Sensor: MAP vs. MAF

The choice between a MAP sensor and a MAF sensor depends on the specific engine application and desired performance characteristics.

- Naturally Aspirated Engines: MAP sensors are typically sufficient for naturally aspirated engines, where intake manifold pressure variations are relatively small.

- Turbocharged or Supercharged Engines: MAF sensors are preferred for turbocharged or supercharged engines, where the intake manifold pressure can fluctuate significantly.

Understanding the Interplay: MAP and MAF in Tandem

While MAP and MAF sensors are often seen as competing technologies, they can also work together in some engine applications. In these systems, the MAP sensor provides a backup measurement of manifold pressure, supplementing the MAF sensor’s primary function of measuring airflow. This dual-sensor approach enhances engine performance and reliability by providing redundancy and improved accuracy.

FAQs: MAP and MAF Sensors

Q: What is the difference between a MAP sensor and a MAF sensor?

A: The MAP sensor measures the pressure in the intake manifold, while the MAF sensor directly measures the mass of air entering the engine.

Q: Which sensor is better?

A: There is no "better" sensor. The choice depends on the engine application and desired performance characteristics. MAF sensors are generally preferred for turbocharged or supercharged engines, while MAP sensors are suitable for naturally aspirated engines.

Q: What happens if a MAP sensor fails?

A: A failing MAP sensor can lead to poor engine performance, rough idling, stalling, and increased emissions.

Q: What happens if a MAF sensor fails?

A: A failing MAF sensor can result in poor fuel economy, reduced engine power, rough idling, and increased emissions.

Q: How do I test a MAP sensor?

A: A MAP sensor can be tested using a multimeter and comparing its readings to the manufacturer’s specifications.

Q: How do I test a MAF sensor?

A: MAF sensors are typically tested using a specialized scan tool or by comparing its readings to the manufacturer’s specifications.

Tips for Maintaining MAP and MAF Sensors:

- Regularly Inspect and Clean: Inspect the sensors for signs of damage, dirt, or debris. Clean the MAF sensor with a specialized cleaner as needed.

- Check for Vacuum Leaks: Inspect the intake manifold for leaks, as they can affect the accuracy of the MAP sensor.

- Avoid Contaminants: Protect the MAF sensor from contaminants by using an air filter and maintaining a clean engine bay.

Conclusion: The Foundation for Efficient Combustion

MAP and MAF sensors are essential components in modern engine management systems, ensuring accurate air-fuel ratios for optimal performance and emissions control. While their methods differ, both sensors play critical roles in measuring airflow, enabling the ECU to precisely control fuel delivery and optimize engine operation. Understanding these sensors and their applications is crucial for any enthusiast or technician involved in maintaining and troubleshooting modern internal combustion engines.

Closure

Thus, we hope this article has provided valuable insights into The Air Intake Guardians: Exploring the Roles of MAP and MAF Sensors in Modern Engines. We hope you find this article informative and beneficial. See you in our next article!