The Bosch 0 261 230 283 MAP Sensor: A Vital Component in Modern Engine Management

Related Articles: The Bosch 0 261 230 283 MAP Sensor: A Vital Component in Modern Engine Management

Introduction

With enthusiasm, let’s navigate through the intriguing topic related to The Bosch 0 261 230 283 MAP Sensor: A Vital Component in Modern Engine Management. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

The Bosch 0 261 230 283 MAP Sensor: A Vital Component in Modern Engine Management

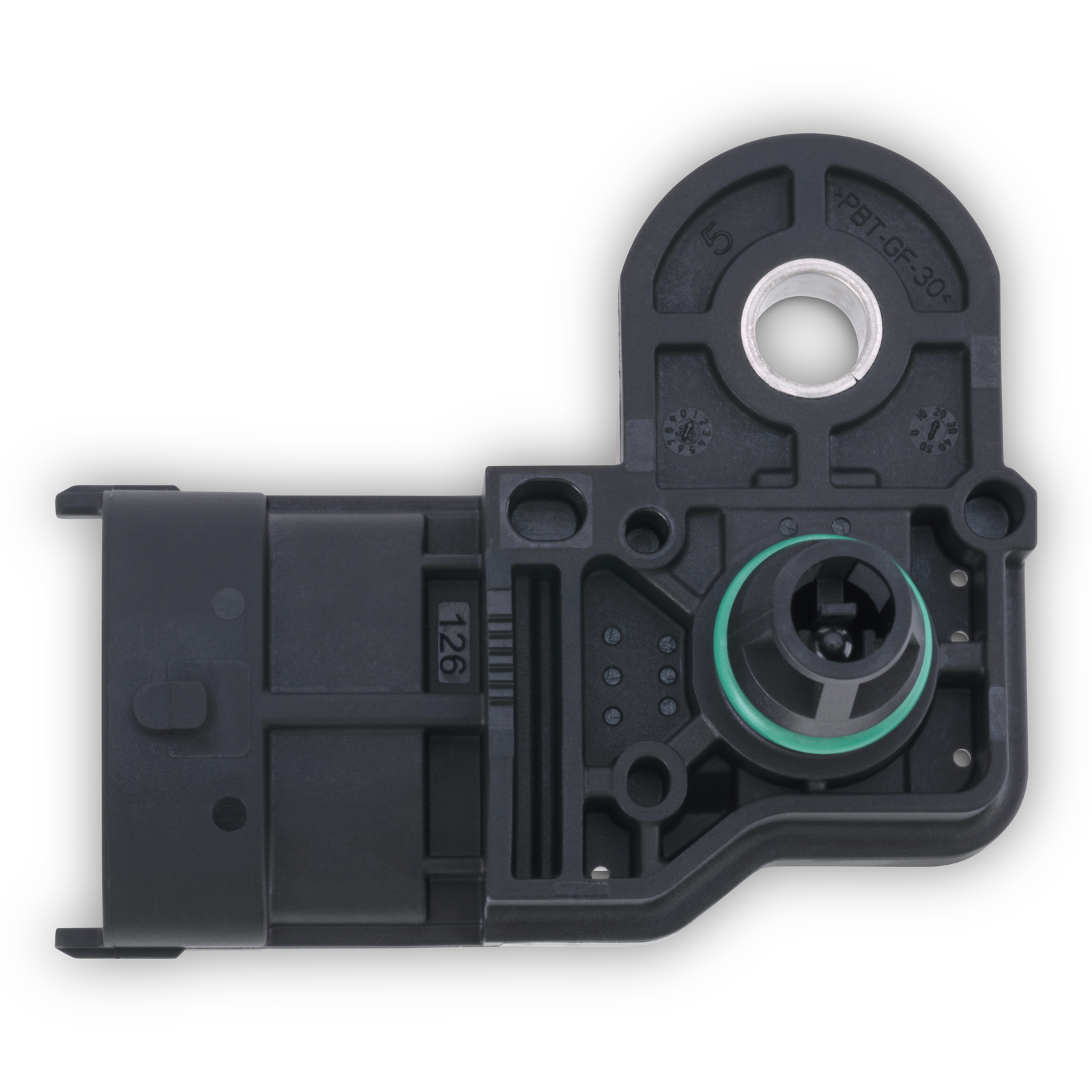

The Bosch 0 261 230 283 MAP sensor, commonly known as a manifold absolute pressure sensor, plays a crucial role in modern engine management systems. This sensor, produced by the renowned automotive technology company Bosch, provides vital information to the engine control unit (ECU) regarding the pressure within the engine’s intake manifold. This information is critical for optimizing fuel delivery, ignition timing, and overall engine performance.

Understanding the Function of the MAP Sensor

The intake manifold, a key component in an internal combustion engine, serves as a conduit for air entering the cylinders. The pressure within the manifold, known as manifold absolute pressure (MAP), directly reflects the volume of air entering the engine. This pressure is constantly fluctuating based on engine speed, load, and throttle position.

The Bosch 0 261 230 283 MAP sensor, a small, typically diaphragm-based device, converts these pressure variations into an electrical signal. This signal is then transmitted to the ECU, which utilizes this data to make critical adjustments to fuel injection and ignition timing.

The Importance of the MAP Sensor in Engine Management

The MAP sensor’s role in optimizing engine performance is multifaceted:

-

Precise Fuel Delivery: The ECU uses the MAP sensor data to calculate the amount of fuel required for optimal combustion. By accurately measuring the air intake volume, the ECU can precisely adjust the fuel injection duration, ensuring a stoichiometric air-fuel mixture for maximum efficiency and reduced emissions.

-

Optimized Ignition Timing: The MAP sensor data also influences the ignition timing. The ECU adjusts the spark timing based on the pressure within the intake manifold, ensuring optimal combustion at different engine loads and speeds. This results in smoother engine operation and improved fuel economy.

-

Enhanced Emissions Control: By ensuring precise fuel delivery and optimal combustion, the MAP sensor plays a vital role in reducing harmful emissions. The ECU, guided by the MAP sensor data, can adjust the fuel-air mixture to minimize pollutants like carbon monoxide, hydrocarbons, and nitrogen oxides.

Common Applications of the Bosch 0 261 230 283 MAP Sensor

The Bosch 0 261 230 283 MAP sensor is widely used in a variety of automotive applications, particularly in vehicles equipped with gasoline internal combustion engines. It is often found in:

-

Passenger Cars: The sensor is a standard component in modern passenger vehicles, ensuring optimal performance and fuel efficiency.

-

Light Trucks and SUVs: The sensor’s ability to handle varying engine loads makes it suitable for light trucks and SUVs, where power and torque are crucial.

-

Performance Vehicles: The Bosch 0 261 230 283 MAP sensor’s precise data acquisition and transmission capabilities make it suitable for performance vehicles where fine-tuned engine management is critical.

Troubleshooting and Maintenance

While the Bosch 0 261 230 283 MAP sensor is a robust and reliable component, it can be susceptible to wear and tear over time. Common issues include:

-

Sensor Failure: The sensor diaphragm can become damaged or its internal circuitry can malfunction, leading to inaccurate pressure readings.

-

Vacuum Leaks: Leaks in the intake manifold or vacuum lines can disrupt the pressure readings, affecting engine performance.

-

Contamination: Dirt, debris, or oil contamination can interfere with the sensor’s operation.

Symptoms of a Faulty MAP Sensor

A malfunctioning MAP sensor can manifest in various symptoms, including:

-

Engine Stalling: Erratic pressure readings can cause the ECU to miscalculate fuel delivery, leading to engine stalling.

-

Rough Idling: An inaccurate pressure reading can disrupt the fuel-air mixture, causing rough idling.

-

Reduced Power: A faulty sensor can result in insufficient fuel delivery, leading to a noticeable decrease in engine power.

-

Increased Fuel Consumption: An inaccurate pressure reading can lead to an overly rich fuel-air mixture, increasing fuel consumption.

-

Check Engine Light: The ECU will often detect a malfunctioning MAP sensor and illuminate the check engine light, providing a clear indication of a potential issue.

FAQs

Q: What is the difference between a MAP sensor and a MAF sensor?

A: While both sensors play crucial roles in engine management, they measure different parameters. A MAP sensor measures the absolute pressure within the intake manifold, while a MAF sensor measures the mass airflow entering the engine.

Q: How can I test my MAP sensor?

A: Testing a MAP sensor requires specialized tools and technical expertise. It is recommended to consult a qualified mechanic for accurate diagnosis and testing.

Q: Can I replace the MAP sensor myself?

A: Replacing a MAP sensor is generally a straightforward process, but it requires basic mechanical skills and knowledge. Refer to your vehicle’s repair manual or consult a professional mechanic for guidance.

Q: How often should I replace the MAP sensor?

A: MAP sensors are generally quite durable and can last for many years. However, if you experience any of the symptoms mentioned above, it’s advisable to have the sensor inspected and potentially replaced.

Tips for Maintaining the MAP Sensor

-

Regular Maintenance: Regularly inspect the intake manifold and vacuum lines for leaks.

-

Cleanliness: Ensure the sensor is kept clean and free of debris.

-

Avoid Oil Contamination: Prevent oil from contaminating the sensor, as this can lead to malfunction.

Conclusion

The Bosch 0 261 230 283 MAP sensor is an essential component in modern engine management systems. Its accurate pressure readings provide the ECU with vital information for optimizing fuel delivery, ignition timing, and overall engine performance. Ensuring the proper functioning of this sensor is crucial for maintaining optimal engine performance, fuel efficiency, and reduced emissions. Regular maintenance and prompt attention to any potential issues can help extend the life of this vital component and ensure smooth, reliable engine operation.

Closure

Thus, we hope this article has provided valuable insights into The Bosch 0 261 230 283 MAP Sensor: A Vital Component in Modern Engine Management. We thank you for taking the time to read this article. See you in our next article!