The Critical Role of Map Testing in Toilet Design and Performance

Related Articles: The Critical Role of Map Testing in Toilet Design and Performance

Introduction

In this auspicious occasion, we are delighted to delve into the intriguing topic related to The Critical Role of Map Testing in Toilet Design and Performance. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

The Critical Role of Map Testing in Toilet Design and Performance

The performance of a toilet is not solely determined by its visual appeal or brand name. Behind the seamless operation and efficient flushing lies a complex interplay of engineering principles, hydraulics, and design elements. Crucially, the success of this intricate system hinges on a rigorous testing process known as "map testing." This process, often conducted in dedicated laboratories, plays a vital role in ensuring the functionality and efficiency of toilets, ultimately benefiting both manufacturers and consumers.

Understanding the Principles of Map Testing

Map testing, also known as "performance testing," is a standardized method employed to evaluate the hydraulic performance of toilets. It involves simulating real-world usage conditions within a controlled environment, meticulously measuring and analyzing key performance indicators. This data provides valuable insights into the toilet’s ability to flush effectively, minimize water consumption, and prevent clogging.

The Process of Map Testing

The map testing process typically involves the following steps:

-

Fixture Preparation: The toilet is carefully installed in a specialized testing apparatus, ensuring accurate alignment and water connections.

-

Water Supply: A controlled water supply is provided, simulating various water pressures commonly found in residential settings.

-

Waste Simulation: A standardized quantity and type of simulated waste material, such as a mixture of water and weighted paper, is introduced into the toilet bowl.

-

Flushing Cycle: The toilet is flushed using a specific flushing cycle, mimicking the typical user behavior.

-

Data Collection: During the flushing cycle, various parameters are meticulously measured and recorded, including:

- Flush Volume: The amount of water used for each flush.

- Flush Time: The duration of the flushing cycle.

- Bowl Height: The height of the water level in the bowl during and after the flush.

- Siphon Action: The strength and duration of the siphon effect, which draws waste out of the bowl.

- Waste Removal: The effectiveness of the flush in removing the simulated waste.

-

Data Analysis: The collected data is analyzed to assess the toilet’s performance against pre-defined standards and benchmarks. This analysis focuses on evaluating factors such as:

- Flushing Efficiency: The effectiveness of the flush in removing waste with minimal water usage.

- Water Conservation: Compliance with water efficiency standards and regulations.

- Clogging Resistance: The ability of the toilet to handle various types of waste without clogging.

- Noise Level: The sound generated during the flushing cycle.

The Importance of Map Testing

Map testing serves as a critical tool for both toilet manufacturers and consumers, offering significant benefits:

-

Ensuring Product Quality: Manufacturers rely on map testing to guarantee the consistent performance of their toilets, ensuring they meet established standards and consumer expectations. This rigorous testing process helps identify potential design flaws or manufacturing inconsistencies, enabling timely corrective measures.

-

Optimizing Water Efficiency: With increasing concerns about water conservation, map testing plays a crucial role in evaluating and improving the water efficiency of toilets. By analyzing flush volumes and flushing times, manufacturers can optimize designs to minimize water consumption while maintaining effective waste removal.

-

Preventing Clogging Issues: Clogging is a common frustration for homeowners, and map testing helps manufacturers design toilets that are resistant to clogging. By simulating various types of waste and analyzing their removal efficiency, manufacturers can ensure the toilet can handle a wide range of materials without clogging.

-

Enhancing User Experience: Map testing contributes to a more positive user experience by ensuring toilets flush efficiently and quietly, minimizing the risk of unpleasant odors or messy spills.

-

Compliance with Standards: Map testing is often mandated by regulatory bodies to ensure toilets meet specific performance standards and water efficiency requirements. This ensures that toilets sold in the market meet certain minimum performance criteria, protecting consumers from purchasing subpar products.

FAQs Regarding Map Testing

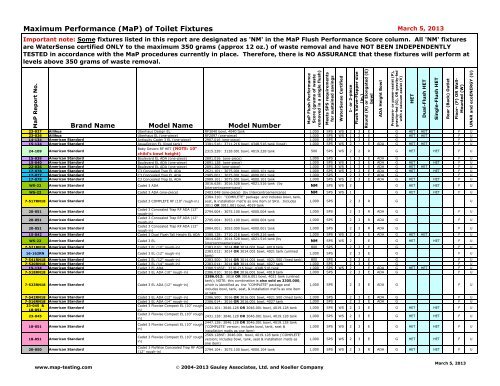

1. What are the standards used in map testing?

The most common standards used in map testing include:

- ASTM F1417: This standard defines the testing methods and performance criteria for water closets. It covers aspects such as flush volume, flush time, bowl height, and waste removal efficiency.

- WaterSense: This program, administered by the U.S. Environmental Protection Agency (EPA), sets water efficiency standards for toilets. Toilets certified by WaterSense must meet stringent criteria for water consumption and performance.

- CSA B45.1: This Canadian standard outlines the requirements for water closets, covering aspects such as flush volume, flush time, and waste removal efficiency.

2. Who conducts map testing?

Map testing is typically conducted by independent testing laboratories accredited by organizations such as:

- IAPMO (International Association of Plumbing and Mechanical Officials): IAPMO is a non-profit organization that develops and administers plumbing and mechanical codes and standards.

- NSF International: NSF is a global public health and safety organization that provides testing and certification services for various products, including toilets.

- UL (Underwriters Laboratories): UL is a global safety science company that provides product safety testing and certification services.

3. How often is map testing required?

Map testing is typically required for each new model of toilet that is introduced to the market. However, some manufacturers may choose to conduct map testing on existing models to ensure continued compliance with standards and to evaluate the effectiveness of design changes.

4. Is map testing a requirement for all toilets?

While map testing is not mandatory for all toilets, it is generally considered best practice for manufacturers to ensure the quality and performance of their products. Many manufacturers voluntarily submit their toilets for map testing to gain a competitive advantage and demonstrate their commitment to high-quality products.

5. Can consumers benefit from map testing?

Consumers benefit from map testing indirectly, as it ensures the toilets they purchase meet established standards and performance criteria. This translates to more reliable and efficient toilets that consume less water and perform effectively.

Tips for Choosing a Toilet Based on Map Testing Results

- Look for WaterSense Certification: WaterSense certification indicates that a toilet meets strict water efficiency standards, ensuring you are making a water-conserving choice.

- Check the Flush Volume: Aim for toilets with lower flush volumes, typically 1.28 gallons per flush or less, as they use less water without compromising performance.

- Consider the Flush Time: A shorter flush time generally indicates a more efficient flush, reducing the risk of clogging and ensuring waste is removed effectively.

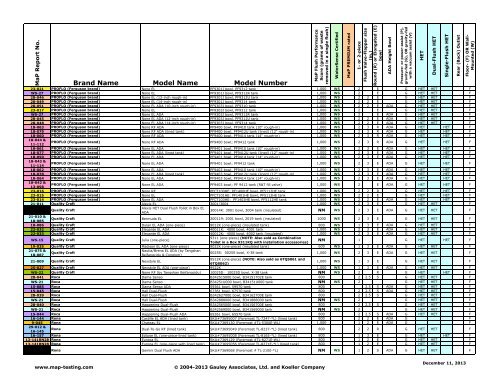

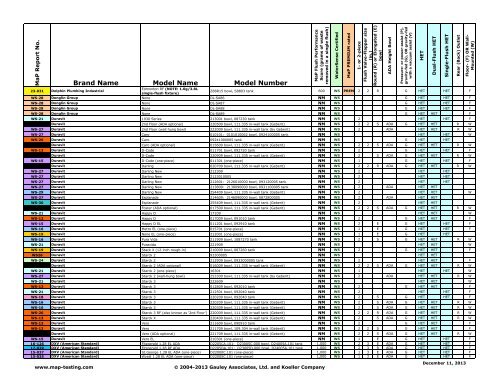

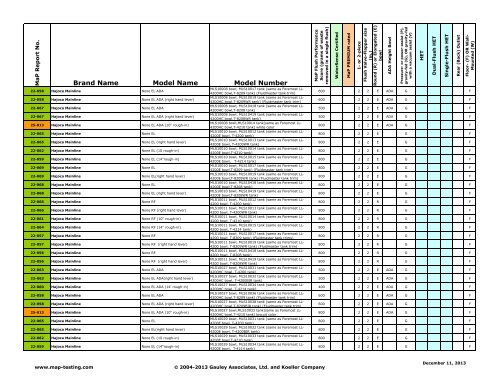

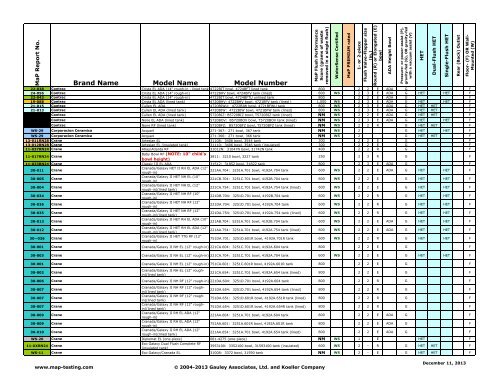

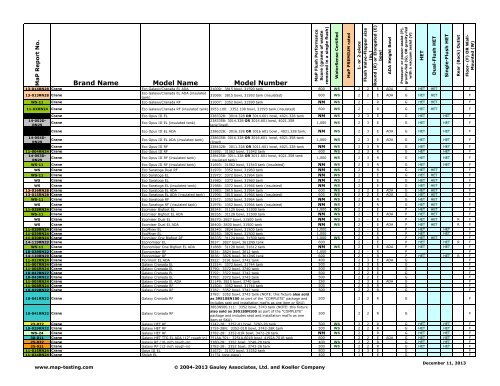

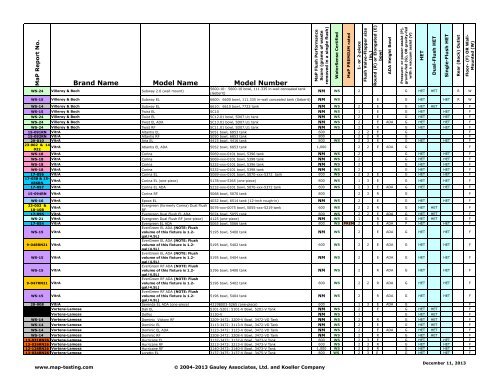

- Read the Test Reports: Many manufacturers provide detailed test reports outlining the performance of their toilets. Review these reports to compare different models and identify the best option for your needs.

Conclusion

Map testing plays a crucial role in ensuring the functionality and efficiency of toilets, benefiting both manufacturers and consumers. By simulating real-world usage conditions and evaluating key performance indicators, map testing provides valuable insights into the toilet’s ability to flush effectively, minimize water consumption, and prevent clogging. This rigorous testing process contributes to the development of high-quality, water-efficient toilets that meet the needs of modern consumers. As we continue to focus on water conservation and sustainability, map testing will remain an essential tool for ensuring the performance and reliability of toilets, ultimately contributing to a more sustainable future.

Closure

Thus, we hope this article has provided valuable insights into The Critical Role of Map Testing in Toilet Design and Performance. We thank you for taking the time to read this article. See you in our next article!