The Crucial Role of Manifold Absolute Pressure Sensors in Modern Engines

Related Articles: The Crucial Role of Manifold Absolute Pressure Sensors in Modern Engines

Introduction

In this auspicious occasion, we are delighted to delve into the intriguing topic related to The Crucial Role of Manifold Absolute Pressure Sensors in Modern Engines. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

The Crucial Role of Manifold Absolute Pressure Sensors in Modern Engines

The intricate dance of combustion within an internal combustion engine relies on a delicate balance of air and fuel. Precisely measuring the amount of air entering the engine’s cylinders is paramount to achieving optimal performance and fuel efficiency. This is where the manifold absolute pressure (MAP) sensor comes into play, acting as a critical component in modern engine management systems.

Understanding the MAP Sensor’s Function

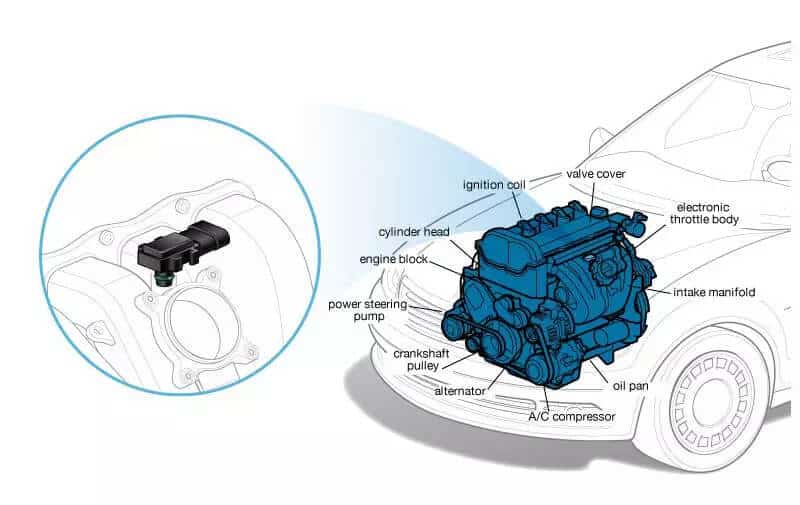

The MAP sensor is a small, often overlooked, yet crucial component responsible for measuring the pressure within the engine’s intake manifold. This pressure, known as manifold absolute pressure, directly reflects the amount of air drawn into the cylinders during the intake stroke.

The MAP sensor’s operation relies on a simple yet effective principle. It contains a diaphragm that flexes in response to pressure changes within the intake manifold. This flexing is measured by a sensor, often a piezoresistive element, which converts the physical movement into an electrical signal. This signal is then transmitted to the engine control unit (ECU), providing vital information about the air intake.

The Importance of Accurate Air Measurement

The data provided by the MAP sensor is essential for the ECU to accurately calculate the optimal fuel-air mixture for combustion. Here’s how:

- Fuel Injection Control: The ECU utilizes the MAP sensor data to determine the precise amount of fuel to inject into the cylinders. By knowing the air intake, the ECU can calculate the ideal fuel-air ratio for efficient combustion and optimal power output.

- Ignition Timing: The MAP sensor also plays a crucial role in optimizing ignition timing. Higher manifold pressure indicates a larger air intake, requiring a slightly delayed ignition timing to prevent knocking or pre-ignition.

- Emissions Control: Accurate air measurement is essential for efficient emissions control. By ensuring the correct fuel-air mixture, the ECU can minimize harmful emissions such as hydrocarbons, carbon monoxide, and nitrogen oxides.

- Boost Control (Turbocharged Engines): In turbocharged engines, the MAP sensor plays a vital role in controlling boost pressure. By monitoring manifold pressure, the ECU can regulate the turbocharger’s boost level, ensuring optimal performance and preventing overboost conditions.

Types of MAP Sensors

MAP sensors come in various designs, with the most common types being:

- Piezoresistive Sensors: These sensors use a thin, flexible diaphragm that changes resistance in response to pressure variations.

- Capacitive Sensors: These sensors employ a capacitor whose capacitance changes based on the pressure applied to a diaphragm.

- Strain Gauge Sensors: These sensors utilize a strain gauge attached to a diaphragm that experiences a change in resistance as the diaphragm deflects due to pressure.

Universal MAP Sensors: A Flexible Solution

Universal MAP sensors are designed to be compatible with a wide range of vehicles and engine applications. These sensors typically offer a standardized electrical connection and pressure range, allowing them to be used in various engine configurations.

Benefits of Universal MAP Sensors:

- Increased Compatibility: Universal MAP sensors provide flexibility for technicians and enthusiasts working on different vehicle models.

- Cost-Effective Solution: Universal sensors often offer a more affordable alternative compared to manufacturer-specific sensors.

- Easy Installation: Universal MAP sensors typically feature a standard connector, simplifying installation and reducing the need for specialized tools.

Troubleshooting MAP Sensor Issues

A faulty MAP sensor can significantly affect engine performance and fuel efficiency. Common symptoms of a malfunctioning MAP sensor include:

- Engine Stalling or Rough Idle: A faulty sensor can lead to an inaccurate fuel-air mixture, resulting in stalling or rough idling.

- Poor Acceleration: An incorrect air reading can hinder the ECU’s ability to deliver the optimal fuel-air mixture, leading to sluggish acceleration.

- Increased Fuel Consumption: An inaccurate air measurement can lead to a rich fuel-air mixture, resulting in increased fuel consumption.

- Check Engine Light (CEL): A malfunctioning MAP sensor will often trigger the CEL, indicating a problem with the sensor or related circuitry.

Tips for Maintaining and Replacing MAP Sensors

- Regular Inspection: Visually inspect the MAP sensor for any signs of damage, corrosion, or debris.

- Clean the Sensor: If necessary, gently clean the sensor with a non-abrasive cleaner and compressed air.

- Replace if Necessary: If the sensor is damaged or malfunctioning, replace it with a new, high-quality sensor.

- Use a Reputable Source: Always purchase MAP sensors from reputable suppliers to ensure compatibility and reliability.

FAQs about MAP Sensors

Q: What is the difference between a MAP sensor and a MAF sensor?

A: While both MAP and MAF sensors are essential for engine management, they measure different parameters. A MAP sensor measures the pressure within the intake manifold, reflecting the amount of air already in the system. Conversely, a MAF sensor measures the mass airflow entering the engine, providing a real-time measurement of air intake.

Q: How can I test a MAP sensor?

A: Testing a MAP sensor requires specialized equipment and knowledge. A technician can use a digital multimeter or a scan tool to check the sensor’s output voltage under different pressure conditions.

Q: Can I replace a MAP sensor myself?

A: Replacing a MAP sensor is generally a straightforward task, but it requires basic mechanical knowledge and familiarity with your vehicle. Consult your owner’s manual or a repair guide for specific instructions.

Q: How long does a MAP sensor last?

A: MAP sensors are typically quite durable and can last for many years with proper care. However, factors such as environmental conditions, engine wear, and driving habits can affect their lifespan.

Conclusion

The MAP sensor, though often overlooked, plays a crucial role in modern engine management systems. It provides vital information about the amount of air entering the engine, enabling the ECU to optimize fuel injection, ignition timing, and emissions control. By understanding the importance of the MAP sensor and its function, vehicle owners and technicians can ensure optimal engine performance, fuel efficiency, and reduced emissions. With proper maintenance and timely replacement when necessary, the MAP sensor continues to be an essential component for ensuring the smooth and efficient operation of modern internal combustion engines.

Closure

Thus, we hope this article has provided valuable insights into The Crucial Role of Manifold Absolute Pressure Sensors in Modern Engines. We appreciate your attention to our article. See you in our next article!