The Crucial Role of Manifold Absolute Pressure Sensors in Modern Engines

Related Articles: The Crucial Role of Manifold Absolute Pressure Sensors in Modern Engines

Introduction

With great pleasure, we will explore the intriguing topic related to The Crucial Role of Manifold Absolute Pressure Sensors in Modern Engines. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

The Crucial Role of Manifold Absolute Pressure Sensors in Modern Engines

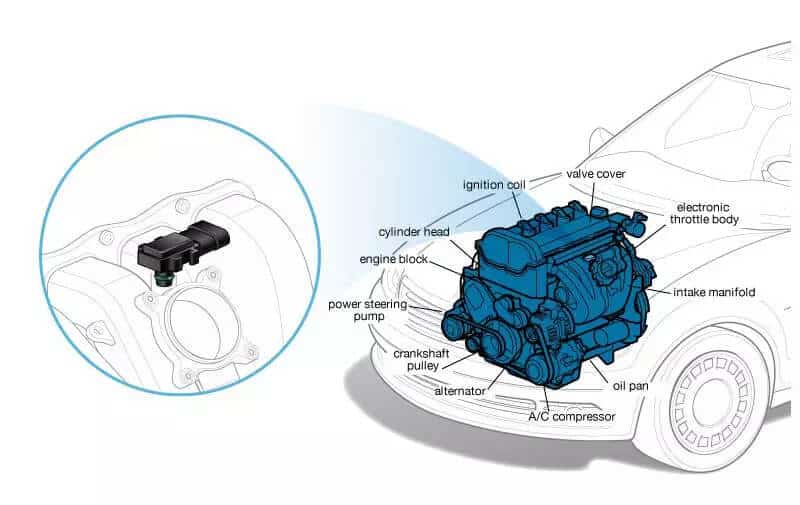

The intricate dance of combustion within an internal combustion engine relies on a delicate balance of air and fuel. To ensure this delicate balance, modern engines employ a multitude of sensors, one of which plays a pivotal role in orchestrating the fuel delivery system: the Manifold Absolute Pressure (MAP) sensor. This unassuming component, often overlooked by casual observers, acts as a silent guardian, providing vital information to the engine control unit (ECU) that dictates fuel injection timing and quantity.

Understanding the MAP Sensor’s Function

The MAP sensor, typically located in the intake manifold, measures the absolute pressure of the air within the manifold. This pressure, often referred to as manifold vacuum, is a direct reflection of the amount of air present in the intake manifold. The sensor converts this pressure into an electrical signal, which is then transmitted to the ECU.

The Interplay Between Pressure and Fuel Delivery

The ECU, armed with the MAP sensor’s data, utilizes this information to calculate the ideal amount of fuel to inject into the engine. The relationship between manifold pressure and fuel delivery is inversely proportional: higher manifold pressure indicates a greater volume of air in the intake manifold, necessitating a richer fuel mixture for optimal combustion. Conversely, lower manifold pressure signals a leaner air-fuel ratio.

The Importance of Precise MAP Sensor Readings

The accuracy of MAP sensor readings is paramount for efficient engine operation and optimal performance. An inaccurate reading can lead to a variety of issues, including:

- Poor fuel economy: An overly rich or lean air-fuel mixture can result in wasted fuel and decreased mileage.

- Reduced engine power: An insufficient fuel mixture can lead to a lack of power and sluggish acceleration.

- Rough idling and stalling: Inaccurate fuel delivery can cause erratic engine operation, including rough idling and stalling.

- Increased emissions: An imbalanced air-fuel mixture can result in increased emissions, contributing to air pollution.

- Engine damage: Extreme cases of inaccurate fuel delivery can lead to engine damage, such as detonation or pre-ignition.

Factors Affecting MAP Sensor Accuracy

Several factors can influence the accuracy of MAP sensor readings, including:

- Vacuum leaks: Leaks in the intake manifold or associated hoses can disrupt the pressure readings, causing inaccurate data.

- Clogged sensor ports: Debris or dirt accumulating within the sensor’s ports can obstruct the flow of air, hindering accurate pressure readings.

- Damaged sensor wiring: Faulty or damaged wiring can interfere with the electrical signal transmission from the sensor to the ECU.

- Environmental factors: Extreme temperatures or humidity can impact the sensor’s performance, affecting its accuracy.

Troubleshooting MAP Sensor Issues

Identifying and resolving issues with the MAP sensor can be crucial for restoring optimal engine performance. Several troubleshooting methods can be employed:

- Visual inspection: A visual inspection of the sensor and its wiring can reveal signs of damage or debris.

- Pressure testing: Using a vacuum gauge, the manifold pressure can be measured and compared to the sensor’s output to detect any discrepancies.

- Diagnostic scan tool: An OBD-II scan tool can retrieve diagnostic trouble codes (DTCs) related to the MAP sensor, providing valuable insights into potential issues.

- Sensor replacement: If the MAP sensor is found to be faulty, it should be replaced with a genuine OE or high-quality aftermarket component.

FAQs Regarding MAP Sensor Readings

Q: What is the typical range of MAP sensor readings?

A: The range of MAP sensor readings varies depending on the engine and its operating conditions. However, typical readings can range from 0 to 100 kPa (kilopascals) or 0 to 15 psi (pounds per square inch).

Q: How can I determine if my MAP sensor is malfunctioning?

A: Several symptoms can indicate a faulty MAP sensor, including rough idling, poor acceleration, decreased fuel economy, and engine stalling. Additionally, an OBD-II scan tool can retrieve DTCs related to the sensor.

Q: Can I clean my MAP sensor?

A: While cleaning the sensor’s ports with compressed air can be helpful, it’s generally recommended to replace a faulty MAP sensor rather than attempt to clean it.

Q: Is it possible to adjust the MAP sensor readings?

A: Adjusting MAP sensor readings is not recommended as it can lead to incorrect air-fuel ratios and engine damage. The sensor should provide accurate readings without any manipulation.

Tips for Maintaining Optimal MAP Sensor Performance

- Regular maintenance: Regular engine maintenance, including air filter replacement and intake manifold inspections, can help prevent debris from accumulating in the sensor’s ports.

- Proper wiring: Ensure that the MAP sensor’s wiring is securely connected and free from damage.

- Quality components: When replacing a faulty MAP sensor, choose a genuine OE or high-quality aftermarket component to ensure accurate readings.

- Professional diagnosis: If you suspect a MAP sensor issue, consult a qualified mechanic for proper diagnosis and repair.

Conclusion

The MAP sensor, often overlooked in the intricate tapestry of engine technology, plays a crucial role in ensuring efficient and reliable engine operation. Its accurate readings provide the ECU with vital information for precise fuel delivery, enabling optimal combustion and performance. Recognizing the importance of this component and taking proactive steps to maintain its performance can contribute significantly to engine longevity and overall vehicle efficiency.

Closure

Thus, we hope this article has provided valuable insights into The Crucial Role of Manifold Absolute Pressure Sensors in Modern Engines. We appreciate your attention to our article. See you in our next article!