The Crucial Role of Manifold Absolute Pressure Sensors in Modern Vehicles: A Comprehensive Guide

Related Articles: The Crucial Role of Manifold Absolute Pressure Sensors in Modern Vehicles: A Comprehensive Guide

Introduction

With great pleasure, we will explore the intriguing topic related to The Crucial Role of Manifold Absolute Pressure Sensors in Modern Vehicles: A Comprehensive Guide. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

The Crucial Role of Manifold Absolute Pressure Sensors in Modern Vehicles: A Comprehensive Guide

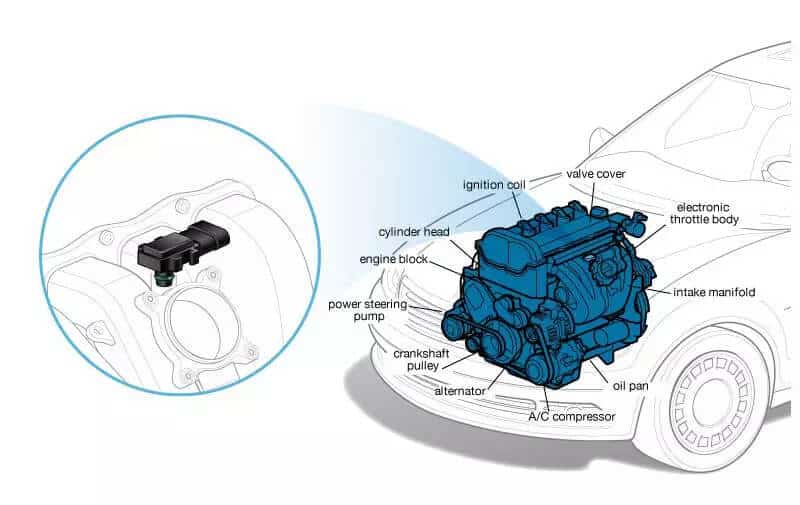

The intricate workings of modern vehicles are a testament to technological advancement, with numerous sensors playing vital roles in ensuring efficient and safe operation. Among these crucial components, the manifold absolute pressure sensor (MAP sensor) stands out as a critical element in the engine control system. This sensor, often identified by specific part numbers like 12614970, provides invaluable information to the engine control unit (ECU) regarding engine load and manifold pressure, directly impacting fuel injection, ignition timing, and overall engine performance.

Understanding the Significance of Manifold Absolute Pressure

The manifold absolute pressure (MAP) is a fundamental parameter that reflects the pressure within the intake manifold of an engine. This pressure, measured in kilopascals (kPa) or inches of mercury (inHg), directly correlates with the amount of air entering the engine during each intake stroke. Higher manifold pressure indicates a greater volume of air entering the cylinders, signifying a heavier engine load.

The Working Principle of a MAP Sensor

MAP sensors, typically employing a piezoresistive or capacitive sensing element, convert the pressure within the intake manifold into an electrical signal. This signal, proportional to the manifold absolute pressure, is transmitted to the ECU for processing.

The Role of MAP Sensors in Engine Control

The information provided by the MAP sensor is crucial for the ECU to make critical adjustments to engine operation, optimizing performance and efficiency. Some key applications include:

- Fuel Injection Control: The ECU uses MAP sensor data to determine the appropriate amount of fuel to inject into the cylinders. Under higher manifold pressure, signifying a heavier engine load, the ECU increases fuel injection to maintain the optimal air-fuel ratio.

- Ignition Timing Control: The ECU adjusts ignition timing based on MAP sensor readings. At higher manifold pressures, the ECU may advance ignition timing to optimize combustion and power output.

- Boost Control (Turbocharged Engines): In turbocharged engines, the ECU uses MAP sensor data to control the boost pressure generated by the turbocharger, ensuring optimal performance and preventing overboost conditions.

- Emissions Control: The ECU leverages MAP sensor readings to control various emissions-related systems, such as the EGR (Exhaust Gas Recirculation) valve, to minimize harmful emissions.

Common Symptoms of a Faulty MAP Sensor

A malfunctioning MAP sensor can lead to a variety of engine performance issues. Some common symptoms include:

- Poor Fuel Economy: An inaccurate MAP reading can result in incorrect fuel injection, leading to excessive fuel consumption.

- Rough Idle: A faulty MAP sensor can cause erratic engine idle, leading to stalling or hesitation.

- Engine Stalling: In extreme cases, a malfunctioning MAP sensor can cause the engine to stall, particularly under heavy load.

- Reduced Power: A faulty MAP sensor can prevent the ECU from accurately adjusting fuel injection and ignition timing, resulting in a noticeable reduction in engine power.

- Check Engine Light (CEL): A malfunctioning MAP sensor will trigger a diagnostic trouble code (DTC) and illuminate the check engine light.

Troubleshooting and Replacing a MAP Sensor

If you suspect a faulty MAP sensor, it is essential to diagnose the problem accurately before attempting any repairs. A mechanic can utilize diagnostic equipment to check for any MAP sensor-related DTCs and monitor the sensor’s output signal.

Replacing a faulty MAP sensor is typically a straightforward process. It involves disconnecting the electrical connector, removing the sensor from its mounting location, and installing the new sensor. However, it is crucial to consult the vehicle’s repair manual or seek professional assistance for accurate installation procedures.

FAQs Regarding MAP Sensors

1. What is the difference between a MAP sensor and a MAF sensor?

While both sensors play crucial roles in engine control, they measure different parameters. A MAP sensor measures the absolute pressure within the intake manifold, while a MAF sensor measures the mass airflow entering the engine.

2. How often should a MAP sensor be replaced?

MAP sensors are generally quite durable and can last for many years. However, they can eventually fail due to wear and tear, environmental factors, or damage. If you experience any of the symptoms mentioned earlier, it is advisable to have the sensor inspected.

3. Can I clean a MAP sensor?

Cleaning a MAP sensor is not recommended. The sensor is a delicate component, and any attempt to clean it can potentially damage the sensing element. If the sensor is dirty, it is best to replace it with a new one.

4. Can a faulty MAP sensor cause a catalytic converter failure?

Yes, a faulty MAP sensor can indirectly contribute to catalytic converter failure. Incorrect fuel injection and ignition timing due to a malfunctioning MAP sensor can lead to increased emissions, potentially damaging the catalytic converter.

5. Is it necessary to reset the ECU after replacing a MAP sensor?

In some cases, it may be necessary to reset the ECU after replacing a MAP sensor. This is because the ECU stores adaptive data related to the sensor’s operation. Resetting the ECU allows it to learn the new sensor’s characteristics.

Tips for Maintaining a MAP Sensor

- Regularly inspect the sensor for any signs of damage or contamination.

- Avoid exposing the sensor to excessive heat or moisture.

- Use high-quality fuel and engine oil to minimize sensor contamination.

Conclusion

The MAP sensor, represented by part numbers like 12614970, plays a crucial role in modern engine control systems. Its accurate measurement of manifold absolute pressure allows the ECU to optimize fuel injection, ignition timing, and boost control, ultimately enhancing engine performance, efficiency, and emissions control. Understanding the significance of the MAP sensor and its potential issues is essential for maintaining optimal vehicle performance and avoiding costly repairs. If you suspect a malfunctioning MAP sensor, it is crucial to have it diagnosed and replaced by a qualified mechanic.

Closure

Thus, we hope this article has provided valuable insights into The Crucial Role of Manifold Absolute Pressure Sensors in Modern Vehicles: A Comprehensive Guide. We appreciate your attention to our article. See you in our next article!