The Crucial Role of Oil Separators in Modern Engines: Ensuring Optimal Performance and Longevity

Related Articles: The Crucial Role of Oil Separators in Modern Engines: Ensuring Optimal Performance and Longevity

Introduction

With great pleasure, we will explore the intriguing topic related to The Crucial Role of Oil Separators in Modern Engines: Ensuring Optimal Performance and Longevity. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

The Crucial Role of Oil Separators in Modern Engines: Ensuring Optimal Performance and Longevity

The modern internal combustion engine, a marvel of engineering, relies on a delicate balance of precision and efficiency to deliver power. However, this intricate system is not immune to the accumulation of unwanted byproducts, particularly in the form of oil mist. To combat this issue and maintain optimal engine performance, a vital component known as the oil separator plays a crucial role.

Understanding the Genesis of Oil Mist

The combustion process within an engine, while generating power, also produces a significant amount of heat. This heat, combined with the pressure generated by the pistons, leads to the vaporization of engine oil. This vaporized oil, known as oil mist, is a byproduct of the engine’s operation and can pose significant problems if left unchecked.

The Detrimental Effects of Oil Mist

Oil mist, if allowed to circulate freely within the engine, can lead to a cascade of detrimental effects:

- Reduced Engine Performance: Oil mist can accumulate on critical engine components like the intake manifold and throttle body, hindering airflow and reducing engine efficiency. This leads to a decrease in power output, sluggish acceleration, and potentially rough idling.

- Increased Fuel Consumption: The buildup of oil residue on critical engine components can impede the smooth flow of air, leading to a richer fuel mixture and increased fuel consumption. This translates to higher operating costs and a heavier environmental footprint.

- Premature Wear and Tear: Oil mist can contribute to the formation of carbon deposits on engine components, leading to premature wear and tear. These deposits can also hinder the proper functioning of sensors, leading to inaccurate readings and potential engine misfires.

- Clogging of the Catalytic Converter: The catalytic converter, a crucial component in reducing harmful emissions, can be clogged by oil mist. This can lead to reduced catalytic efficiency, increased emissions, and potential damage to the converter itself.

The Oil Separator: A Lifeline for Engine Health

To mitigate these detrimental effects, oil separators are employed to capture and remove oil mist from the engine’s crankcase ventilation system. These devices act as a barrier, preventing oil mist from reaching sensitive engine components and ensuring clean air intake.

How Oil Separators Work: A Detailed Look

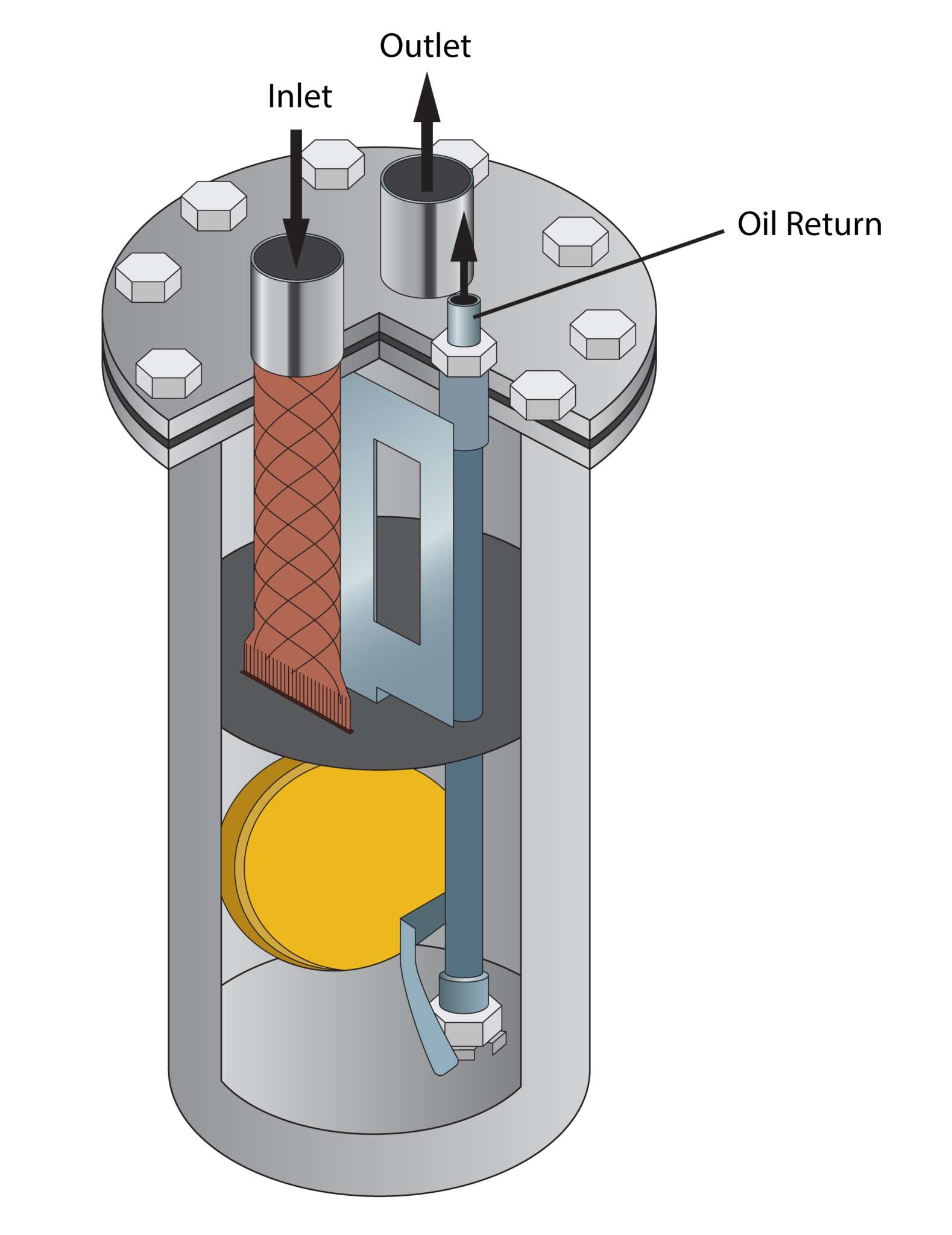

Oil separators operate on the principle of centrifugal force. They use a combination of physical barriers and specialized materials to separate the oil mist from the crankcase ventilation air.

- Centrifugal Force: As the crankcase ventilation air enters the separator, it is forced to spin rapidly. This centrifugal force pushes the heavier oil droplets towards the outer walls of the separator, where they are collected.

- Filter Media: The separator typically contains a filter media, such as a mesh or a series of baffles, which further traps the oil droplets. This filter media also helps to remove any larger particles or debris that may be present in the ventilation air.

- Drainage System: The collected oil is then drained back into the engine’s sump through a dedicated drainage system. This ensures that the oil is not wasted but rather returned to the engine where it can be used again.

Types of Oil Separators: A Comprehensive Overview

Oil separators come in various forms, each tailored to specific engine applications and requirements.

- Centrifugal Separators: These are the most common type of oil separator and utilize centrifugal force to separate oil mist from the ventilation air. They are typically found in modern gasoline and diesel engines.

- Membrane Separators: These separators employ a semi-permeable membrane to filter out oil droplets. The membrane allows air to pass through but traps the oil droplets, preventing them from reaching the intake manifold.

- Cyclone Separators: These separators use a swirling air flow to separate oil mist. The air is forced to spin in a cylindrical chamber, causing the oil droplets to be thrown outwards and collected at the bottom of the chamber.

- Electrostatic Separators: These separators use an electric field to attract and collect oil droplets. The electric field creates a charge on the oil droplets, causing them to adhere to the collector plates.

The Importance of Regular Maintenance

Like any other engine component, oil separators require regular maintenance to ensure optimal performance. This typically involves cleaning or replacing the filter media at specific intervals, depending on the manufacturer’s recommendations. Neglecting maintenance can lead to a reduction in the separator’s effectiveness and ultimately impact engine performance.

Benefits of Using an Oil Separator

The use of an oil separator offers numerous benefits, contributing to a healthier and more efficient engine:

- Improved Engine Performance: By removing oil mist from the intake manifold, oil separators enhance airflow and improve engine performance. This results in smoother acceleration, better fuel economy, and reduced emissions.

- Extended Engine Life: By preventing the accumulation of oil residue on engine components, oil separators reduce wear and tear, extending the engine’s lifespan.

- Reduced Maintenance Costs: By minimizing the buildup of carbon deposits, oil separators contribute to cleaner engine operation, reducing the frequency of engine cleaning and potentially saving on maintenance costs.

- Enhanced Environmental Protection: By reducing oil mist emissions, oil separators contribute to cleaner air and a reduced environmental impact.

FAQs Regarding Oil Separators

1. Is an oil separator a mandatory component in all engines?

While oil separators are becoming increasingly common in modern engines, they are not mandatory in all vehicles. The presence of an oil separator depends on the specific engine design and manufacturer’s specifications.

2. Can I install an oil separator on my older car?

Yes, you can install an aftermarket oil separator on older vehicles. However, it is crucial to ensure compatibility with your specific engine model and to seek professional installation to avoid potential issues.

3. How often should I clean or replace the oil separator?

The frequency of cleaning or replacement depends on the type of oil separator and the manufacturer’s recommendations. Typically, it is recommended to check the separator’s condition every 30,000 to 50,000 miles or as part of your regular maintenance schedule.

4. Can I clean the oil separator myself?

Cleaning an oil separator can be done by removing it from the engine, disassembling it, and cleaning the filter media with a suitable solvent. However, it is essential to follow the manufacturer’s instructions carefully and to use appropriate cleaning agents.

5. What are the signs of a faulty oil separator?

Signs of a faulty oil separator can include a decrease in engine performance, increased fuel consumption, smoke from the exhaust, or oil buildup on engine components. If you notice any of these symptoms, it is recommended to have your oil separator inspected by a qualified mechanic.

Tips for Maintaining Your Oil Separator

- Regular Inspection: Regularly inspect the oil separator for any signs of oil leaks, damage, or excessive buildup of oil residue.

- Cleaning or Replacement: Follow the manufacturer’s recommendations for cleaning or replacing the oil separator.

- High-Quality Oil: Use high-quality engine oil that is compatible with your vehicle. This will help to minimize oil mist formation.

- Proper Maintenance: Ensure regular engine maintenance, including oil changes and air filter replacements. This will help to prevent excessive oil buildup and ensure optimal engine performance.

Conclusion: The Importance of Oil Separators in Modern Engines

Oil separators play a crucial role in maintaining optimal engine performance and longevity. By effectively removing oil mist from the crankcase ventilation system, they prevent the accumulation of harmful deposits on critical engine components, ensuring smoother operation, increased fuel efficiency, and reduced emissions. Regular maintenance and proper care of your oil separator are essential for maximizing its effectiveness and safeguarding your engine’s health. Investing in a well-functioning oil separator is an investment in the long-term performance and reliability of your vehicle, ensuring a smoother driving experience and reducing the risk of costly repairs down the line.

Closure

Thus, we hope this article has provided valuable insights into The Crucial Role of Oil Separators in Modern Engines: Ensuring Optimal Performance and Longevity. We appreciate your attention to our article. See you in our next article!