The Crucial Role of the Manifold Absolute Pressure Sensor in Chevrolet Blazer Performance

Related Articles: The Crucial Role of the Manifold Absolute Pressure Sensor in Chevrolet Blazer Performance

Introduction

With enthusiasm, let’s navigate through the intriguing topic related to The Crucial Role of the Manifold Absolute Pressure Sensor in Chevrolet Blazer Performance. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

The Crucial Role of the Manifold Absolute Pressure Sensor in Chevrolet Blazer Performance

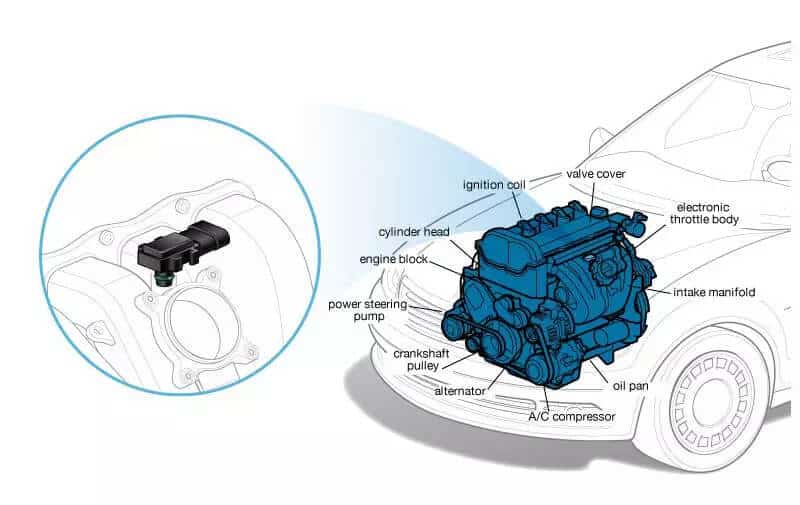

The Chevrolet Blazer, a popular SUV known for its ruggedness and versatility, relies on a complex network of sensors to ensure optimal engine performance. Among these vital components is the Manifold Absolute Pressure (MAP) sensor, a small but crucial device that plays a significant role in determining the engine’s air intake and ultimately, its power output.

Understanding the MAP Sensor’s Function

The MAP sensor, typically located on the intake manifold, serves as a critical link between the engine’s intake system and the engine control unit (ECU). Its primary function is to measure the absolute pressure within the intake manifold. This pressure, which is directly proportional to the amount of air entering the cylinders, provides the ECU with valuable information about the engine’s load and operating conditions.

How the MAP Sensor Works

The MAP sensor employs a specialized pressure-sensitive diaphragm that flexes in response to changes in manifold pressure. This flexing action alters the resistance within an electrical circuit, which is then interpreted by the ECU. The ECU uses this information to calculate the precise amount of fuel required for optimal combustion, ensuring efficient engine operation.

The Importance of a Functional MAP Sensor

A properly functioning MAP sensor is essential for several reasons:

- Accurate Fuel Delivery: The MAP sensor provides the ECU with vital data for calculating the ideal fuel-air mixture. A faulty sensor can lead to an inaccurate mixture, resulting in poor fuel economy, reduced power, and even engine damage.

- Smooth Engine Performance: A properly calibrated MAP sensor ensures a consistent fuel-air ratio, leading to smoother engine operation and reduced emissions.

- Optimized Engine Control: The MAP sensor’s readings are used by the ECU to control various engine functions, including ignition timing, throttle response, and emissions control. A faulty sensor can disrupt these processes, affecting overall engine performance.

Common Symptoms of a Failing MAP Sensor

A malfunctioning MAP sensor can manifest in various symptoms, including:

- Engine Stalling: An inaccurate fuel-air mixture can cause the engine to stall, especially at idle or during acceleration.

- Rough Idle: A faulty MAP sensor can lead to an uneven engine idle, resulting in rough vibrations and inconsistent performance.

- Reduced Power: A malfunctioning sensor can disrupt the fuel-air mixture, leading to a loss of engine power.

- Increased Emissions: An inaccurate fuel-air mixture can result in increased emissions, potentially failing emissions tests.

- Check Engine Light: The ECU will often illuminate the check engine light if it detects a malfunctioning MAP sensor.

Diagnosing a Failing MAP Sensor

Diagnosing a failing MAP sensor requires a combination of visual inspection, diagnostic testing, and careful observation of the vehicle’s performance.

- Visual Inspection: Check the MAP sensor for any visible damage, loose connections, or signs of corrosion.

- Diagnostic Testing: A scan tool can be used to read the MAP sensor’s readings and compare them to factory specifications.

- Performance Observation: Pay close attention to any of the symptoms mentioned above, as they can indicate a malfunctioning sensor.

Replacing a Failing MAP Sensor

Replacing a faulty MAP sensor is a relatively straightforward procedure that can be performed by a qualified mechanic. However, it is important to ensure that the replacement sensor is compatible with the specific vehicle model and year.

FAQs about the MAP Sensor in Chevrolet Blazers

Q: What are the most common reasons for a MAP sensor failure?

A: Common reasons for MAP sensor failure include:

- Contamination: Dust, dirt, or debris can accumulate on the sensor’s diaphragm, affecting its ability to respond accurately.

- Electrical Problems: A faulty electrical connection or a damaged wiring harness can disrupt the sensor’s signal.

- Mechanical Damage: The sensor’s diaphragm can be damaged by excessive pressure or physical impact.

- Age and Wear: Like any mechanical component, the MAP sensor can wear out over time, requiring replacement.

Q: How often should the MAP sensor be replaced?

A: The MAP sensor’s lifespan varies depending on factors such as driving conditions and maintenance practices. However, it is generally recommended to replace the sensor every 50,000 to 100,000 miles, or sooner if any signs of malfunction are detected.

Q: Can I clean a faulty MAP sensor?

A: Cleaning a contaminated MAP sensor may temporarily improve its performance. However, if the sensor is damaged or worn out, cleaning will not resolve the issue.

Q: Can I replace the MAP sensor myself?

A: Replacing a MAP sensor is a relatively simple procedure, but it requires some basic mechanical knowledge. If you are not comfortable performing the task yourself, it is recommended to consult a qualified mechanic.

Tips for Maintaining the MAP Sensor

- Regular Maintenance: Ensure the engine’s intake system is clean and free of debris to prevent contamination of the MAP sensor.

- Avoid Excessive Pressure: Avoid subjecting the engine to excessive pressure, as it can damage the sensor’s diaphragm.

- Inspect Connections: Regularly inspect the MAP sensor’s electrical connections for any signs of corrosion or damage.

- Professional Inspections: Have the MAP sensor inspected by a qualified mechanic during routine maintenance intervals.

Conclusion

The MAP sensor is an integral component of the Chevrolet Blazer’s engine management system, playing a crucial role in ensuring optimal fuel efficiency, engine performance, and reduced emissions. By understanding the sensor’s function, recognizing potential issues, and following proper maintenance practices, owners can ensure that their Blazer continues to perform reliably and efficiently. A properly functioning MAP sensor contributes significantly to a smooth, powerful, and enjoyable driving experience.

Closure

Thus, we hope this article has provided valuable insights into The Crucial Role of the Manifold Absolute Pressure Sensor in Chevrolet Blazer Performance. We appreciate your attention to our article. See you in our next article!