The Crucial Role of the Manifold Absolute Pressure Sensor in Modern Automotive Systems

Related Articles: The Crucial Role of the Manifold Absolute Pressure Sensor in Modern Automotive Systems

Introduction

With enthusiasm, let’s navigate through the intriguing topic related to The Crucial Role of the Manifold Absolute Pressure Sensor in Modern Automotive Systems. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

The Crucial Role of the Manifold Absolute Pressure Sensor in Modern Automotive Systems

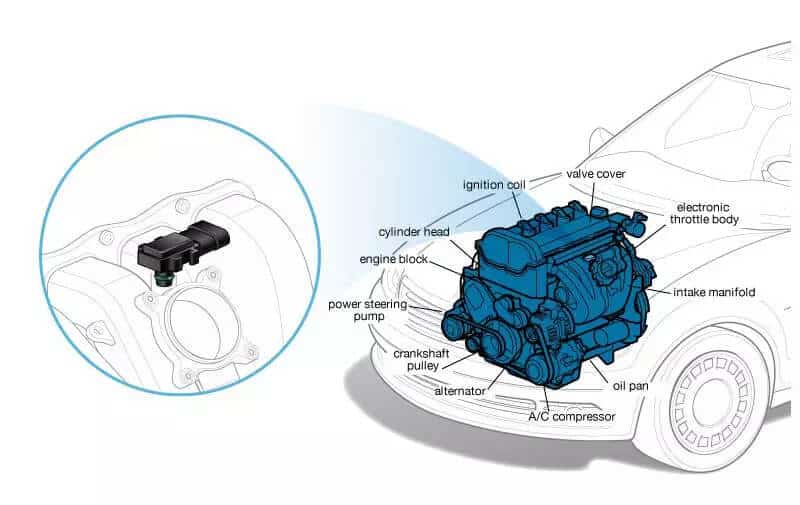

The intricate dance of combustion within an internal combustion engine is a delicate balance of fuel, air, and timing. To ensure optimal performance and efficiency, the engine control unit (ECU) requires precise information about the conditions inside the engine’s intake manifold. This is where the manifold absolute pressure (MAP) sensor, a critical component in modern automotive systems, plays a pivotal role.

Understanding the MAP Sensor’s Function

The MAP sensor, often referred to as a "manifold pressure sensor," is a small, electromechanical device responsible for measuring the absolute pressure within the intake manifold. This pressure, which represents the amount of air present in the manifold, is directly proportional to the engine’s load. The MAP sensor converts this pressure reading into an electrical signal, transmitting it to the ECU for analysis.

The Importance of Precise Pressure Readings

The ECU relies heavily on the MAP sensor’s readings to make critical decisions regarding engine operation. These decisions include:

- Fuel Injection Timing and Duration: The ECU uses the MAP sensor data to determine the optimal timing and duration of fuel injection, ensuring the correct fuel-air mixture for efficient combustion.

- Ignition Timing: The ECU adjusts ignition timing based on the MAP sensor readings, optimizing combustion for maximum power output and fuel economy.

- Air-Fuel Ratio Control: The MAP sensor provides crucial information for controlling the air-fuel ratio, ensuring a balance that promotes complete combustion and reduces emissions.

- Throttle Position Sensing: In some vehicles, the MAP sensor may also be used to determine throttle position, providing the ECU with additional information about driver input.

How the MAP Sensor Works

The MAP sensor typically employs a diaphragm-based pressure sensing mechanism. A thin, flexible diaphragm is exposed to the intake manifold pressure. As pressure changes, the diaphragm deflects, altering the resistance of a strain gauge or other sensing element. This change in resistance is converted into an electrical signal, which the ECU interprets as a pressure reading.

Common Types of MAP Sensors

While the basic principle of operation remains the same, MAP sensors come in various configurations. Some common types include:

- Piezoresistive MAP Sensors: These sensors utilize a piezoresistive element, whose resistance changes proportionally to applied pressure.

- Capacitive MAP Sensors: Capacitive MAP sensors measure changes in capacitance between two plates, one of which is exposed to the intake manifold pressure.

- Strain Gauge MAP Sensors: These sensors employ a strain gauge, which experiences a change in resistance when subjected to pressure-induced deformation.

Identifying a Faulty MAP Sensor

A malfunctioning MAP sensor can significantly impact engine performance and fuel efficiency. Common symptoms of a faulty MAP sensor include:

- Rough Idle: An inaccurate pressure reading can lead to an uneven fuel-air mixture, resulting in a rough idle.

- Stalling: In extreme cases, a faulty MAP sensor can cause the engine to stall due to incorrect fuel delivery.

- Poor Acceleration: A faulty MAP sensor can hinder acceleration by causing an incorrect air-fuel mixture, resulting in a lack of power.

- Increased Fuel Consumption: An inaccurate pressure reading can lead to a richer fuel-air mixture, causing increased fuel consumption.

- Check Engine Light: A faulty MAP sensor will typically trigger a check engine light, indicating a problem with the engine’s emissions or performance.

Troubleshooting a Faulty MAP Sensor

If you suspect a faulty MAP sensor, it’s essential to have it diagnosed and replaced by a qualified mechanic. However, some basic troubleshooting steps can help identify the issue:

- Visual Inspection: Check for any visible damage to the sensor, such as cracks or loose connections.

- Vacuum Test: Use a vacuum gauge to check the intake manifold pressure and compare it to the MAP sensor reading.

- Electrical Testing: Use a multimeter to test the sensor’s electrical output and compare it to the manufacturer’s specifications.

Benefits of a Properly Functioning MAP Sensor

A properly functioning MAP sensor is crucial for:

- Optimized Engine Performance: Accurate pressure readings ensure efficient combustion, maximizing power output and fuel economy.

- Reduced Emissions: Proper fuel-air mixture control minimizes harmful emissions, contributing to cleaner air quality.

- Improved Driveability: A well-functioning MAP sensor ensures smooth acceleration and a responsive engine, enhancing the overall driving experience.

FAQs About the Manifold Absolute Pressure Sensor

Q: What is the difference between a MAP sensor and a MAF sensor?

A: The MAP sensor measures the absolute pressure within the intake manifold, while the Mass Air Flow (MAF) sensor measures the mass of air entering the engine. Both sensors provide critical information to the ECU for optimal engine control.

Q: Can I replace the MAP sensor myself?

A: While replacing a MAP sensor is a relatively straightforward task, it requires some mechanical knowledge and specialized tools. It’s recommended to have a qualified mechanic perform the replacement to ensure proper installation and avoid potential damage.

Q: How often should I replace the MAP sensor?

A: MAP sensors typically have a long lifespan, but they can wear out over time. However, there is no set replacement interval. If you experience any of the symptoms mentioned above, it’s advisable to have the sensor inspected and replaced if necessary.

Q: Can a faulty MAP sensor cause damage to other engine components?

A: While a faulty MAP sensor won’t directly damage other engine components, it can lead to improper engine operation, which can indirectly contribute to wear and tear on other parts.

Tips for Maintaining a Healthy MAP Sensor

- Regular Maintenance: Ensure regular maintenance of your vehicle, including oil changes and air filter replacements, as these can indirectly affect the MAP sensor’s performance.

- Avoid Extreme Temperatures: Prolonged exposure to extreme temperatures can damage the sensor’s internal components.

- Inspect for Leaks: Check for any leaks in the intake manifold or vacuum lines, as these can affect the accuracy of the pressure readings.

Conclusion

The manifold absolute pressure sensor plays a critical role in modern automotive systems, providing the ECU with vital information about the conditions within the intake manifold. This information is essential for optimizing engine performance, fuel efficiency, and emissions control. A properly functioning MAP sensor ensures a smooth, responsive, and efficient driving experience. Regular maintenance and timely replacement of a faulty sensor are crucial for maintaining optimal engine performance and longevity.

Closure

Thus, we hope this article has provided valuable insights into The Crucial Role of the Manifold Absolute Pressure Sensor in Modern Automotive Systems. We hope you find this article informative and beneficial. See you in our next article!