The Crucial Role of the Manifold Absolute Pressure Sensor Seal in Engine Performance

Related Articles: The Crucial Role of the Manifold Absolute Pressure Sensor Seal in Engine Performance

Introduction

With great pleasure, we will explore the intriguing topic related to The Crucial Role of the Manifold Absolute Pressure Sensor Seal in Engine Performance. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

The Crucial Role of the Manifold Absolute Pressure Sensor Seal in Engine Performance

The intricate dance of combustion within an internal combustion engine relies on a delicate balance of air and fuel. Ensuring this precise mixture is the responsibility of the engine control unit (ECU), which utilizes various sensors to gather real-time data about the engine’s operating conditions. One such crucial sensor, the manifold absolute pressure (MAP) sensor, plays a vital role in this process, providing the ECU with information about the pressure inside the engine’s intake manifold.

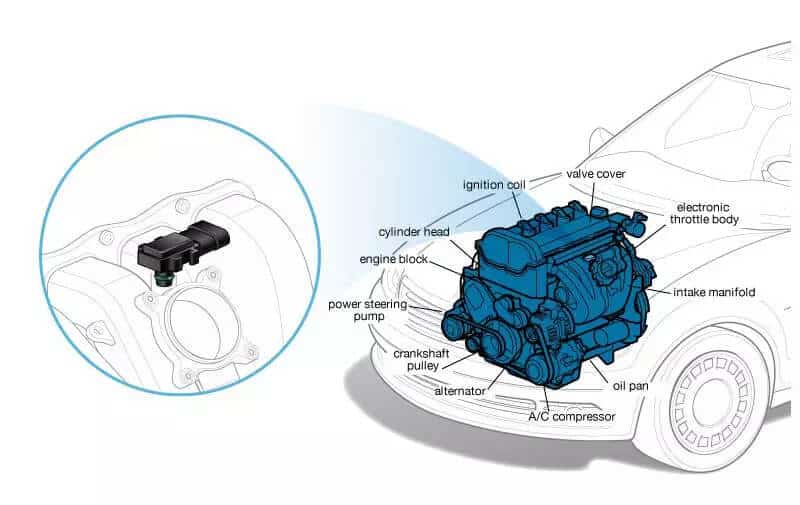

The MAP sensor itself is a relatively simple device, essentially a pressure transducer that converts the pressure within the intake manifold into an electrical signal. This signal is then relayed to the ECU, which uses it to calculate the amount of fuel needed for optimal combustion. However, for the MAP sensor to function accurately, it requires a tight seal to prevent leaks that could disrupt the pressure readings. This is where the MAP sensor seal comes into play.

The Importance of the MAP Sensor Seal

The MAP sensor seal, typically a small rubber or plastic ring, acts as a barrier between the sensor and the intake manifold. It ensures a leak-proof connection, preventing air from entering the intake manifold at points other than the throttle body. This is crucial for maintaining accurate pressure readings within the manifold.

Consequences of a Faulty MAP Sensor Seal

A compromised MAP sensor seal, whether due to wear, damage, or improper installation, can lead to a range of engine performance issues. These issues arise from the inaccurate pressure readings received by the ECU, causing it to miscalculate the required fuel-air mixture.

- Engine Misfire: Inaccurate pressure readings can lead to an incorrect fuel-air ratio, resulting in a lean or rich mixture. This can cause engine misfires, leading to rough idling, reduced power, and increased emissions.

- Poor Fuel Economy: A faulty seal can result in the ECU delivering too much or too little fuel, impacting fuel efficiency and increasing fuel consumption.

- Check Engine Light: The ECU monitors the MAP sensor readings and will trigger a check engine light if it detects inconsistencies, indicating a potential problem with the sensor or its seal.

- Engine Stalling: In extreme cases, a severe leak can cause the ECU to receive inaccurate pressure readings, leading to the engine stalling or refusing to start.

Identifying a Faulty MAP Sensor Seal

While a faulty MAP sensor seal can manifest in various ways, several signs can indicate a potential issue:

- Vacuum Leaks: A hissing sound around the MAP sensor can be a telltale sign of a leak.

- Engine Performance Issues: The symptoms mentioned above, such as misfiring, rough idling, or decreased fuel economy, can be indicators of a faulty seal.

- Check Engine Light: A check engine light illuminated with a code related to the MAP sensor or intake manifold pressure can point to a problem with the seal.

Replacing a Faulty MAP Sensor Seal

Replacing a faulty MAP sensor seal is a relatively straightforward procedure that can be performed by a qualified mechanic or a DIY enthusiast with basic mechanical skills. The process typically involves:

- Locating the MAP Sensor: The MAP sensor is usually located on the intake manifold, often near the throttle body.

- Disconnecting the Sensor: Disconnect the electrical connector and any vacuum lines connected to the sensor.

- Removing the Old Seal: Carefully remove the old seal, ensuring no debris is left behind.

- Installing the New Seal: Install the new seal, ensuring it is properly seated and free of damage.

- Reconnecting the Sensor: Reconnect the electrical connector and vacuum lines, ensuring they are secure.

- Clearing the Check Engine Light: After installation, use a scan tool to clear the check engine light and ensure the new seal resolves the issue.

Tips for Maintaining the MAP Sensor Seal

- Regular Inspections: Inspect the MAP sensor seal for signs of wear, damage, or cracking during routine maintenance checks.

- Proper Installation: When replacing the seal, ensure it is properly seated and free of damage to prevent leaks.

- Cleanliness: Keep the area around the MAP sensor clean and free of debris to prevent contamination and potential seal damage.

- Professional Assistance: If you are unsure about replacing the seal, consult a qualified mechanic for professional assistance.

FAQs about the MAP Sensor Seal

Q: How often should I replace the MAP sensor seal?

A: The lifespan of a MAP sensor seal can vary depending on factors like the quality of the seal, environmental conditions, and vehicle usage. However, it is generally recommended to inspect the seal every 20,000-30,000 miles or as part of routine maintenance.

Q: Can I use a generic seal for my MAP sensor?

A: It is not recommended to use a generic seal as it may not fit properly or provide the necessary seal, leading to leaks and performance issues. Always use a seal specifically designed for your vehicle’s MAP sensor.

Q: Can a faulty MAP sensor seal cause a check engine light?

A: Yes, a faulty seal can cause the ECU to receive inaccurate pressure readings, triggering a check engine light with a code related to the MAP sensor or intake manifold pressure.

Q: What are the potential consequences of ignoring a faulty MAP sensor seal?

A: Ignoring a faulty seal can lead to various engine performance issues, including misfires, poor fuel economy, increased emissions, and even engine stalling. Addressing the issue promptly is crucial for maintaining optimal engine performance and preventing further complications.

Conclusion

The MAP sensor seal, though seemingly insignificant, plays a crucial role in ensuring accurate pressure readings within the intake manifold. A faulty seal can disrupt the delicate balance of air and fuel, leading to a cascade of engine performance issues. By understanding the importance of the seal, recognizing the signs of a faulty one, and taking prompt action to replace it, you can ensure optimal engine performance, fuel efficiency, and a smooth driving experience.

Closure

Thus, we hope this article has provided valuable insights into The Crucial Role of the Manifold Absolute Pressure Sensor Seal in Engine Performance. We hope you find this article informative and beneficial. See you in our next article!