The Crucial Role of the MAP Sensor Connector Pigtail in Automotive Systems

Related Articles: The Crucial Role of the MAP Sensor Connector Pigtail in Automotive Systems

Introduction

With enthusiasm, let’s navigate through the intriguing topic related to The Crucial Role of the MAP Sensor Connector Pigtail in Automotive Systems. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

The Crucial Role of the MAP Sensor Connector Pigtail in Automotive Systems

![]()

The intricate network of sensors and actuators within a modern vehicle relies on a complex system of electrical connections. One critical component in this network is the MAP sensor connector pigtail, a seemingly simple yet indispensable element that plays a vital role in ensuring proper engine operation and vehicle performance. This article delves into the significance of the MAP sensor connector pigtail, exploring its function, its impact on engine performance, and the potential consequences of its malfunction.

Understanding the MAP Sensor and its Function

The Manifold Absolute Pressure (MAP) sensor is an integral part of a vehicle’s engine management system, responsible for measuring the pressure within the intake manifold. This pressure, directly related to the amount of air entering the engine, is a crucial parameter for determining the optimal fuel-air mixture for combustion.

The MAP sensor, typically a small, sealed unit, converts the pressure information into an electrical signal that is transmitted to the engine control unit (ECU). The ECU then uses this data to calculate the appropriate fuel injection timing and duration, ensuring optimal engine performance and fuel efficiency.

The MAP Sensor Connector Pigtail: The Conduit of Information

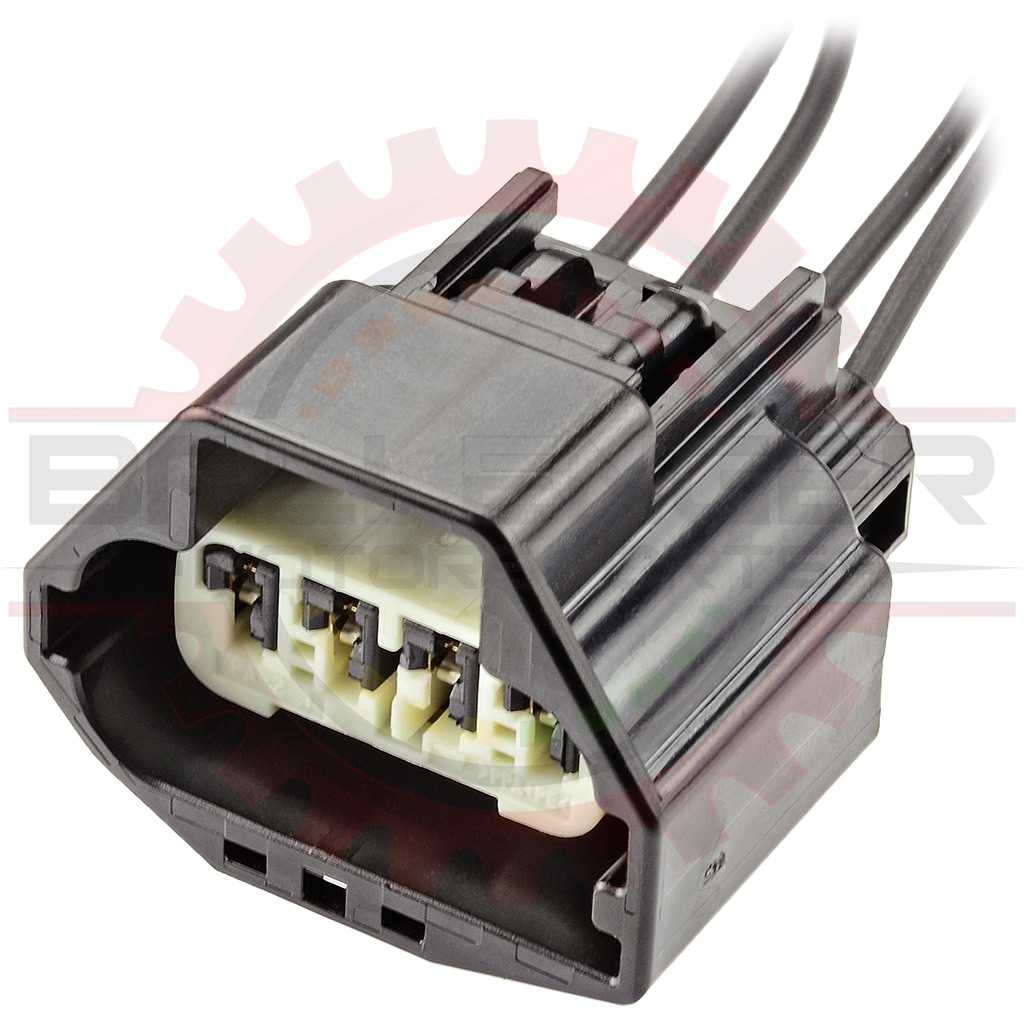

The MAP sensor connector pigtail acts as the vital link between the MAP sensor and the ECU, facilitating the transmission of critical pressure data. It is a short, flexible cable with a connector at each end, one connecting to the sensor and the other to the ECU’s wiring harness.

The pigtail houses multiple wires, each carrying a specific electrical signal. These wires are insulated to prevent short circuits and ensure reliable data transfer. The connector design ensures a secure and robust connection, preventing accidental disconnection or damage that could disrupt the data flow.

The Importance of a Functional MAP Sensor Connector Pigtail

The MAP sensor connector pigtail’s role in the engine management system cannot be overstated. Its proper functioning directly impacts the accuracy of the pressure data transmitted to the ECU, influencing:

-

Engine Performance: A faulty pigtail can lead to inaccurate pressure readings, causing the ECU to miscalculate fuel injection parameters. This can result in:

- Rough idling: Inconsistent fuel delivery leads to uneven combustion, resulting in engine vibration and instability.

- Reduced power: Incorrect fuel-air mixture reduces combustion efficiency, leading to a noticeable decrease in engine power.

- Poor acceleration: The engine struggles to respond smoothly to throttle inputs due to inconsistent fuel delivery.

- Increased fuel consumption: The engine runs inefficiently, leading to higher fuel consumption.

- Emission problems: The incorrect fuel-air ratio can lead to increased emissions, potentially failing emissions testing.

-

Engine Safety: In extreme cases, a faulty pigtail can lead to engine damage due to:

- Detonation: Incorrect fuel-air mixture can cause uncontrolled combustion, leading to engine knock or detonation, potentially causing damage to internal engine components.

- Engine stalling: In severe cases, the ECU might fail to receive accurate pressure data, leading to engine stalling, particularly under high load conditions.

Potential Causes of MAP Sensor Connector Pigtail Malfunction

While the MAP sensor connector pigtail is designed for durability, several factors can contribute to its malfunction:

-

Physical damage: The pigtail, being exposed to the harsh environment under the hood, can be susceptible to damage from:

- Abrasion: Contact with engine components or sharp edges can cause wear and tear on the insulation and wiring.

- Heat: Prolonged exposure to high engine temperatures can cause insulation to melt or crack, leading to short circuits.

- Moisture: Water ingress can corrode the connector terminals, disrupting the electrical connection.

-

Corrosion: Exposure to moisture and road salt can cause corrosion on the connector terminals, hindering the flow of electrical signals.

-

Connector wear: Repeated connection and disconnection can wear down the connector terminals, leading to loose connections and signal interruptions.

-

Wiring issues: Broken or damaged wiring within the pigtail can disrupt the electrical signal transmission.

Identifying and Addressing MAP Sensor Connector Pigtail Issues

Identifying a faulty MAP sensor connector pigtail often requires a combination of diagnostic procedures:

- Visual inspection: Carefully inspect the pigtail for signs of damage, such as frayed wires, melted insulation, or corrosion on the connectors.

- Continuity test: Use a multimeter to test the continuity of each wire within the pigtail, ensuring a complete electrical circuit.

- Voltage test: Measure the voltage at the MAP sensor connector to confirm that the sensor is receiving power and transmitting data.

- Diagnostic scan tool: Use a scan tool to check for error codes related to the MAP sensor or the engine control system.

If a faulty pigtail is suspected, it should be replaced with a new, high-quality component. Avoid using aftermarket pigtails that may not meet the original equipment manufacturer’s (OEM) specifications, as these could lead to further issues.

FAQs

Q: How do I know if my MAP sensor connector pigtail is faulty?

A: Signs of a faulty MAP sensor connector pigtail include rough idling, reduced power, poor acceleration, increased fuel consumption, engine stalling, or engine trouble codes related to the MAP sensor.

Q: Can I repair a damaged MAP sensor connector pigtail?

A: It is generally not recommended to repair a damaged MAP sensor connector pigtail. The wires and connectors are designed for specific electrical resistance and conductivity, and any repair attempt might compromise the signal integrity.

Q: Can I replace the MAP sensor connector pigtail myself?

A: Replacing the MAP sensor connector pigtail is a relatively simple procedure that can be done by a competent DIY mechanic. However, it is essential to follow the manufacturer’s instructions and use proper tools and materials to ensure a safe and successful repair.

Q: How often should I inspect the MAP sensor connector pigtail?

A: It is advisable to visually inspect the MAP sensor connector pigtail during routine maintenance checks, particularly if the vehicle is exposed to harsh environmental conditions.

Tips for Maintaining the MAP Sensor Connector Pigtail

- Regularly inspect: Visually inspect the MAP sensor connector pigtail during routine maintenance checks for any signs of wear, damage, or corrosion.

- Avoid harsh chemicals: When cleaning the engine bay, avoid using harsh chemicals that can damage the pigtail’s insulation or connectors.

- Proper routing: Ensure the pigtail is routed away from potential sources of heat, abrasion, or moisture.

- Use quality replacements: If a replacement is needed, choose a high-quality OEM or reputable aftermarket pigtail that meets the original specifications.

Conclusion

The MAP sensor connector pigtail is a seemingly inconspicuous yet vital component in the intricate network of automotive sensors and actuators. Its function as a conduit for pressure data plays a crucial role in ensuring optimal engine performance, fuel efficiency, and overall vehicle operation. Recognizing the importance of a functional MAP sensor connector pigtail and implementing proper maintenance practices can prevent potential issues and ensure the long-term health of your vehicle’s engine management system.

![]()

Closure

Thus, we hope this article has provided valuable insights into The Crucial Role of the MAP Sensor Connector Pigtail in Automotive Systems. We thank you for taking the time to read this article. See you in our next article!