The Crucial Role of the MAP Sensor Wiring Harness in Modern Vehicles

Related Articles: The Crucial Role of the MAP Sensor Wiring Harness in Modern Vehicles

Introduction

In this auspicious occasion, we are delighted to delve into the intriguing topic related to The Crucial Role of the MAP Sensor Wiring Harness in Modern Vehicles. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

The Crucial Role of the MAP Sensor Wiring Harness in Modern Vehicles

The intricate network of wires and connectors that link the manifold absolute pressure (MAP) sensor to the engine control unit (ECU) is more than just a bundle of cables. This wiring harness, often overlooked in the grand scheme of vehicle systems, plays a vital role in ensuring the smooth and efficient operation of a modern internal combustion engine.

Understanding the MAP Sensor and Its Importance

The MAP sensor, a key component in the engine’s electronic control system, measures the absolute pressure within the intake manifold. This pressure, which fluctuates based on engine load and speed, provides the ECU with crucial information about the amount of air entering the engine. The ECU uses this information to determine the optimal fuel injection timing and duration, ultimately influencing the engine’s power output, fuel efficiency, and emissions.

The Vital Link: The MAP Sensor Wiring Harness

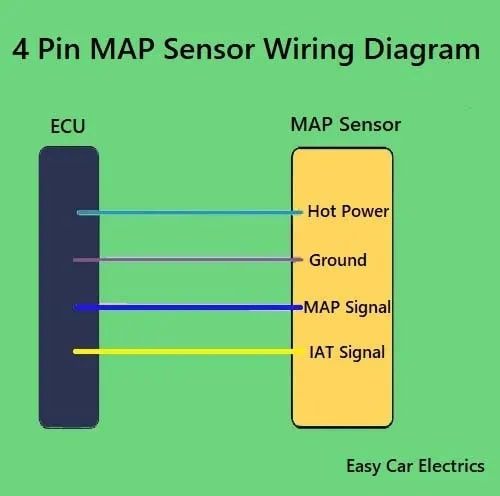

The MAP sensor wiring harness acts as the vital communication bridge between the sensor and the ECU. It carries the electrical signals generated by the MAP sensor, transmitting them accurately and reliably to the ECU. The harness consists of several wires, each dedicated to a specific function:

- Power Supply: Provides the MAP sensor with the necessary electrical power to operate.

- Signal Wire: Carries the analog voltage signal generated by the MAP sensor, representing the measured manifold pressure.

- Ground Wire: Provides a common electrical ground reference for the sensor and ECU.

Consequences of a Faulty Wiring Harness

A malfunctioning MAP sensor wiring harness can disrupt the flow of critical information to the ECU, leading to a range of engine problems:

- Rough Idling: An inaccurate pressure reading can cause the ECU to miscalculate the fuel injection timing, resulting in an uneven engine idle.

- Stalling: In extreme cases, a faulty harness can lead to a complete loss of engine power, causing the vehicle to stall.

- Reduced Fuel Efficiency: Incorrect fuel-air mixture due to faulty pressure readings can significantly decrease fuel economy.

- Increased Emissions: A malfunctioning MAP sensor can contribute to higher emissions, potentially leading to failed emissions tests.

- Check Engine Light: A faulty wiring harness will often trigger a check engine light, indicating a problem with the engine’s electronic control system.

Troubleshooting a Faulty Wiring Harness

Diagnosing a faulty MAP sensor wiring harness requires a systematic approach:

- Visual Inspection: Examine the harness for signs of damage, such as frayed wires, broken connectors, or corrosion.

- Continuity Test: Use a multimeter to test the continuity of each wire in the harness, ensuring a complete electrical path between the sensor and the ECU.

- Voltage Check: Measure the voltage at the sensor’s power and signal wires to confirm proper power supply and signal transmission.

- Pressure Test: Use a vacuum pump or pressure gauge to test the MAP sensor itself, ensuring it’s functioning correctly.

Addressing Wiring Harness Issues

Once a faulty MAP sensor wiring harness is identified, the appropriate repair depends on the nature of the problem:

- Minor Damage: If the damage is localized, repair or replace the affected section of the harness.

- Extensive Damage: In cases of severe damage, replacing the entire harness is often the most effective solution.

- Connector Issues: Replace damaged or corroded connectors with new ones, ensuring a secure and reliable connection.

Benefits of a Properly Functioning Wiring Harness

A properly functioning MAP sensor wiring harness offers numerous benefits:

- Optimal Engine Performance: Accurate pressure readings ensure optimal fuel-air mixture, leading to smoother engine operation, improved power output, and increased fuel efficiency.

- Reduced Emissions: Precise control over fuel injection timing contributes to lower emissions, meeting environmental regulations.

- Enhanced Reliability: A reliable wiring harness ensures consistent communication between the sensor and ECU, minimizing the risk of engine problems and breakdowns.

- Extended Component Lifespan: Proper signal transmission protects the MAP sensor and ECU from potential damage caused by electrical malfunctions.

FAQs About the MAP Sensor Wiring Harness

Q: Can I repair a damaged MAP sensor wiring harness myself?

A: While minor repairs are possible, replacing the entire harness or dealing with complex wiring issues is best left to qualified automotive technicians.

Q: How often should I inspect the MAP sensor wiring harness?

A: Regular visual inspections during routine maintenance checks are recommended. If you notice any signs of damage or suspect a problem, consult a professional.

Q: Can a faulty MAP sensor wiring harness cause other engine problems?

A: Yes, a faulty harness can lead to a cascade of problems, including damage to the MAP sensor, ECU, or other engine components.

Q: What are the signs of a faulty MAP sensor wiring harness?

A: Common signs include rough idling, stalling, reduced fuel efficiency, increased emissions, and a check engine light.

Q: How can I prevent damage to the MAP sensor wiring harness?

A: Avoid exposing the harness to extreme temperatures, moisture, and physical damage. Ensure proper routing and secure connections.

Tips for Maintaining the MAP Sensor Wiring Harness

- Regular Inspections: Visual inspections during routine maintenance checks can identify potential problems early.

- Proper Routing: Ensure the harness is routed away from heat sources, sharp edges, and moving parts.

- Secure Connections: Verify that all connectors are properly secured and free from corrosion.

- Professional Repairs: For any significant damage or complex repairs, seek professional assistance from a qualified automotive technician.

Conclusion

The MAP sensor wiring harness, though often overlooked, plays a vital role in ensuring the proper functioning of a modern engine. Its accurate transmission of pressure readings allows the ECU to optimize fuel injection timing, ultimately impacting engine performance, fuel efficiency, and emissions. Regular inspections, proper maintenance, and prompt repairs are crucial to ensure the reliability and longevity of this critical component.

Closure

Thus, we hope this article has provided valuable insights into The Crucial Role of the MAP Sensor Wiring Harness in Modern Vehicles. We thank you for taking the time to read this article. See you in our next article!