The Delicate Balance: Understanding Why Manifold Absolute Pressure (MAP) Sensors Fail

Related Articles: The Delicate Balance: Understanding Why Manifold Absolute Pressure (MAP) Sensors Fail

Introduction

In this auspicious occasion, we are delighted to delve into the intriguing topic related to The Delicate Balance: Understanding Why Manifold Absolute Pressure (MAP) Sensors Fail. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

The Delicate Balance: Understanding Why Manifold Absolute Pressure (MAP) Sensors Fail

The manifold absolute pressure (MAP) sensor, a critical component in modern internal combustion engines, plays a vital role in ensuring optimal engine performance and fuel efficiency. Its primary function is to measure the pressure within the engine’s intake manifold, providing the engine control unit (ECU) with crucial information for calculating fuel injection timing and air-to-fuel ratios. This intricate process, however, is susceptible to various factors that can lead to the sensor’s deterioration and eventual failure.

The Anatomy of a MAP Sensor: A Closer Look

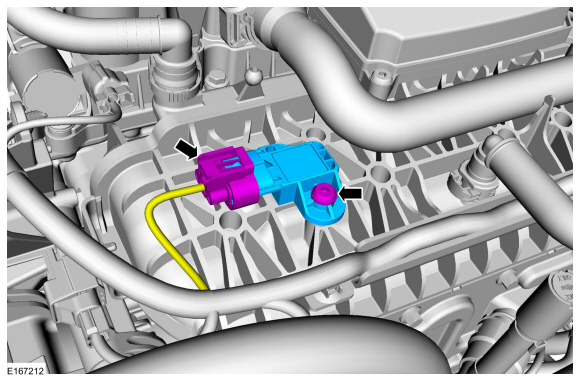

MAP sensors are typically diaphragm-based devices, comprising a sealed chamber with a flexible diaphragm. This diaphragm is connected to a pressure-sensitive element, often a strain gauge or a piezoresistive element. When pressure changes occur within the intake manifold, the diaphragm flexes, altering the resistance of the pressure-sensitive element. This change in resistance is then translated into a voltage signal by the sensor’s internal circuitry, which is ultimately sent to the ECU.

Common Culprits: Unveiling the Reasons Behind MAP Sensor Failure

The intricate workings of a MAP sensor make it susceptible to various factors that can compromise its functionality. These factors can be broadly categorized as follows:

1. Environmental Factors:

- Contamination: The intake manifold is exposed to a variety of contaminants, including dust, dirt, oil, and fuel vapors. These contaminants can accumulate on the sensor’s diaphragm or internal circuitry, interfering with its ability to detect pressure changes accurately.

- Extreme Temperatures: Prolonged exposure to high temperatures, especially in demanding driving conditions, can cause the sensor’s internal components to degrade or even melt, leading to malfunction. Similarly, exposure to extremely low temperatures can affect the sensor’s sensitivity and response time.

- Vibrations and Shocks: Frequent engine vibrations or sudden shocks can cause physical damage to the sensor’s delicate internal components, leading to internal short circuits or broken connections.

2. Mechanical Issues:

- Diaphragm Failure: Over time, the sensor’s diaphragm can become brittle, torn, or lose its elasticity due to wear and tear, resulting in inaccurate pressure readings.

- Sensor Housing Leakage: Cracks or leaks in the sensor’s housing can allow contaminants to enter the internal chamber, affecting the sensor’s performance.

- Internal Circuitry Failure: The sensor’s internal circuitry can be affected by corrosion, oxidation, or manufacturing defects, leading to an inability to generate accurate voltage signals.

3. Electrical Malfunctions:

- Damaged Wiring: Worn or damaged wiring connecting the sensor to the ECU can disrupt the signal transmission, leading to inaccurate or inconsistent readings.

- Loose Connections: Loose connections between the sensor and its wiring harness can cause intermittent or complete loss of signal, affecting the ECU’s ability to receive accurate pressure data.

- ECU Malfunction: While less common, a malfunctioning ECU can misinterpret the signals sent by the MAP sensor, leading to incorrect fuel injection and timing adjustments.

The Ripple Effect: Recognizing the Consequences of a Failing MAP Sensor

A faulty MAP sensor can have significant repercussions on engine performance and fuel efficiency. Here are some common symptoms that indicate a potential problem:

- Engine Stalling or Rough Idling: The ECU relies on accurate pressure readings from the MAP sensor to maintain a smooth idle. A faulty sensor can disrupt this balance, causing the engine to stall or idle roughly.

- Poor Acceleration and Reduced Power: A faulty MAP sensor can lead to incorrect fuel-air mixtures, resulting in reduced power output and sluggish acceleration.

- Increased Fuel Consumption: An inaccurate pressure reading can cause the ECU to inject more fuel than necessary, leading to increased fuel consumption and reduced fuel efficiency.

- Check Engine Light (CEL): A malfunctioning MAP sensor will often trigger a check engine light, indicating a fault in the engine’s emissions control system.

- Black Smoke from Exhaust: A faulty MAP sensor can cause the engine to run rich, leading to excessive fuel combustion and black smoke emission from the exhaust.

Navigating the Diagnosis: Recognizing the Signs and Identifying the Issue

Diagnosing a faulty MAP sensor often involves a combination of visual inspection, diagnostic testing, and performance evaluation.

- Visual Inspection: Inspecting the sensor for physical damage, contamination, or loose connections can provide valuable clues about the potential cause of failure.

- Diagnostic Testing: Utilizing an OBD-II scanner to read fault codes related to the MAP sensor can pinpoint specific issues and provide further insight into the problem.

- Performance Evaluation: Observing engine behavior under various conditions, such as acceleration, deceleration, and idling, can help identify symptoms associated with a faulty MAP sensor.

Remedies and Prevention: Ensuring Optimal Engine Health

Once a faulty MAP sensor is identified, it’s essential to replace it with a genuine or high-quality aftermarket part. Replacing the sensor is typically a straightforward procedure, but it’s always recommended to consult a qualified mechanic for proper installation and calibration.

To prevent premature MAP sensor failure, consider these preventive measures:

- Regular Maintenance: Regularly servicing the engine, including air filter replacement and intake manifold cleaning, can minimize the buildup of contaminants that can affect the sensor’s performance.

- High-Quality Fuel: Using high-quality fuel with appropriate additives can help prevent fuel-related contaminants from reaching the sensor.

- Proper Driving Habits: Avoiding aggressive driving habits and excessive engine revving can minimize vibrations and shocks that can damage the sensor.

FAQs: Addressing Common Concerns

Q: How long does a MAP sensor typically last?

A: The lifespan of a MAP sensor can vary depending on various factors, including driving conditions, maintenance practices, and environmental exposure. However, a properly maintained sensor can typically last for several years, even exceeding 100,000 miles.

Q: Can I clean a MAP sensor?

A: While cleaning a MAP sensor might seem tempting, it’s generally not recommended. The delicate internal components are susceptible to damage during cleaning, and the process can often introduce more contaminants than it removes.

Q: How much does a MAP sensor replacement cost?

A: The cost of a MAP sensor replacement can vary depending on the vehicle make and model, as well as the specific sensor part. However, the average cost for a replacement sensor and labor can range from $100 to $300.

Tips for Maintaining a Healthy MAP Sensor

- Regularly inspect the sensor for signs of damage or contamination.

- Replace the air filter at the recommended intervals.

- Avoid using fuel additives that can potentially harm the sensor.

- Have the intake manifold inspected and cleaned periodically.

- Consider using a fuel system cleaner to help prevent fuel-related contaminants.

Conclusion

The MAP sensor plays a crucial role in maintaining optimal engine performance and fuel efficiency. Understanding the factors that contribute to its failure and implementing preventive measures can significantly extend its lifespan and ensure reliable engine operation. By recognizing the signs of a failing MAP sensor and addressing the issue promptly, drivers can avoid potential performance problems and maintain a healthy and efficient engine.

Closure

Thus, we hope this article has provided valuable insights into The Delicate Balance: Understanding Why Manifold Absolute Pressure (MAP) Sensors Fail. We hope you find this article informative and beneficial. See you in our next article!