The Haltech 4 Bar MAP Sensor: A Deeper Dive into Engine Management Precision

Related Articles: The Haltech 4 Bar MAP Sensor: A Deeper Dive into Engine Management Precision

Introduction

With great pleasure, we will explore the intriguing topic related to The Haltech 4 Bar MAP Sensor: A Deeper Dive into Engine Management Precision. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

The Haltech 4 Bar MAP Sensor: A Deeper Dive into Engine Management Precision

The Haltech 4 Bar MAP sensor, a cornerstone of high-performance engine management systems, plays a pivotal role in determining engine load and optimizing fuel delivery. This sensor, unlike its standard 1 bar counterpart, boasts a significantly extended pressure range, allowing for more precise readings in high-boost applications. This increased accuracy translates to improved engine performance, fuel efficiency, and overall drivability.

Understanding the Essence of MAP Sensors

MAP (Manifold Absolute Pressure) sensors are crucial components in modern engine management systems. They measure the absolute pressure within the intake manifold, providing the engine control unit (ECU) with vital information about engine load. This load information, combined with other sensor data like throttle position and engine speed, allows the ECU to calculate the precise amount of fuel and ignition timing required for optimal combustion.

The Advantages of a 4 Bar MAP Sensor

While standard 1 bar MAP sensors suffice for naturally aspirated engines, their limited pressure range becomes a bottleneck in turbocharged or supercharged applications. Turbochargers, in particular, generate significant boost pressure, exceeding the capabilities of a 1 bar sensor. This limitation leads to inaccurate readings, potentially resulting in:

- Rich Fueling: The ECU may overcompensate for perceived high load, leading to excessive fuel delivery and reduced fuel efficiency.

- Detonation: Erroneous fuel calculations can cause pre-ignition or detonation, damaging engine components.

- Suboptimal Performance: The engine may not achieve its full potential due to inaccurate fuel and ignition timing adjustments.

The Haltech 4 Bar MAP Sensor: A Solution for High-Performance Applications

The Haltech 4 Bar MAP sensor, with its extended pressure range of up to 4 bar (58 psi), addresses these limitations head-on. This increased range allows the sensor to accurately measure boost pressure even under extreme conditions, providing the ECU with precise data for optimal engine control.

Key Benefits of the Haltech 4 Bar MAP Sensor:

- Accurate Boost Measurement: The sensor accurately measures boost pressure, ensuring precise engine load calculations.

- Precise Fuel Delivery: The ECU can accurately determine fuel requirements, optimizing fuel efficiency and reducing emissions.

- Reduced Detonation Risk: Accurate fuel and ignition timing adjustments minimize the risk of detonation, protecting engine components.

- Enhanced Performance: The engine operates at its peak potential, delivering maximum power and responsiveness.

- Increased Flexibility: The sensor can be used in a wide range of applications, from street-driven vehicles to high-performance race cars.

Beyond Performance: The Importance of Installation and Calibration

While the Haltech 4 Bar MAP sensor offers significant advantages, its proper installation and calibration are crucial for optimal performance. A poorly installed sensor or inaccurate calibration can lead to inaccurate readings and potential engine damage.

Installation Considerations:

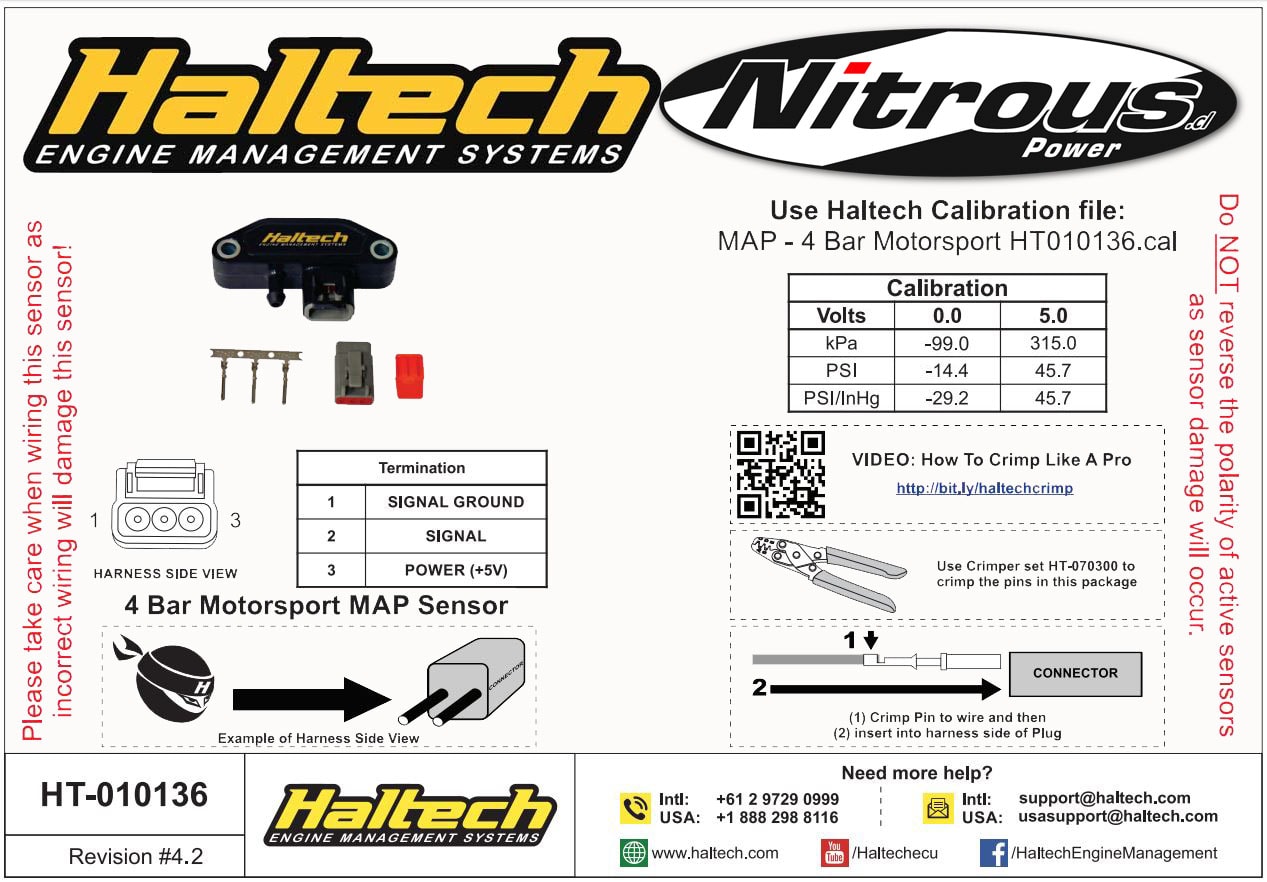

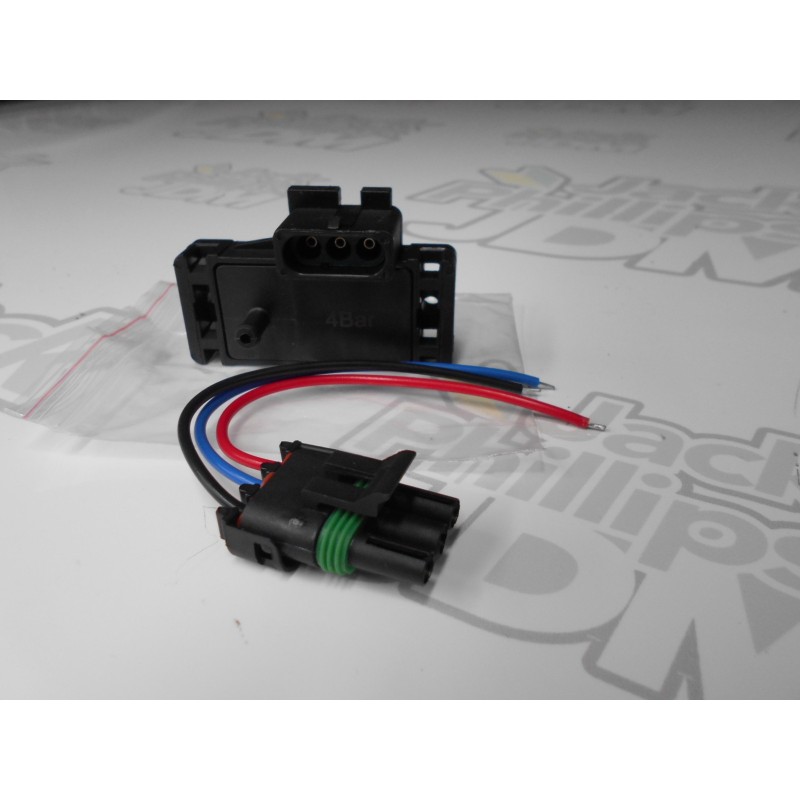

- Sensor Location: The sensor should be mounted in a location where it is exposed to the intake manifold pressure but shielded from extreme temperatures or vibrations.

- Proper Connections: The sensor wiring should be securely connected to the ECU, ensuring a reliable electrical signal.

- Vacuum Lines: If applicable, vacuum lines should be leak-free and properly routed to ensure accurate pressure readings.

Calibration Procedures:

- ECU Settings: The ECU must be configured to recognize the 4 Bar MAP sensor and adjust its parameters accordingly.

- Boost Pressure Calibration: The sensor needs to be calibrated against a known boost pressure source to ensure accurate readings.

- Fine Tuning: After initial calibration, fine-tuning may be required based on engine performance and data analysis.

FAQs about the Haltech 4 Bar MAP Sensor

Q: What is the difference between a 1 bar and a 4 bar MAP sensor?

A: A 1 bar MAP sensor is designed for naturally aspirated engines and can only measure up to 1 bar (14.5 psi) of pressure. A 4 bar MAP sensor can measure up to 4 bar (58 psi) of pressure, making it suitable for turbocharged or supercharged engines.

Q: Is a 4 bar MAP sensor necessary for all turbocharged cars?

A: While a 4 bar MAP sensor is recommended for most turbocharged cars, it’s not always essential. If the boost pressure remains below 1 bar, a 1 bar MAP sensor might suffice. However, for higher boost applications, a 4 bar sensor is crucial for accurate engine management.

Q: Can I use a 4 bar MAP sensor on a naturally aspirated engine?

A: Yes, you can use a 4 bar MAP sensor on a naturally aspirated engine. However, the ECU will need to be configured accordingly, and the sensor will be operating outside its optimal range.

Q: How do I calibrate a 4 bar MAP sensor?

A: Calibration involves adjusting the ECU settings to match the sensor’s output with known pressure readings. This can be done using a boost pressure gauge and adjusting the ECU parameters until the readings align.

Q: What are the potential risks of using a 4 bar MAP sensor?

A: If the sensor is not properly installed or calibrated, it can lead to inaccurate readings, potentially causing rich fueling, detonation, or other engine problems.

Tips for Using a Haltech 4 Bar MAP Sensor

- Choose the Right Sensor: Ensure the sensor is compatible with your ECU and meets the specific requirements of your engine.

- Professional Installation: Consider having a qualified technician install the sensor to ensure proper placement and wiring.

- Thorough Calibration: Calibrate the sensor carefully using a reliable boost pressure gauge and follow the ECU’s instructions.

- Regular Maintenance: Inspect the sensor and its wiring periodically to ensure proper functionality and prevent issues.

Conclusion

The Haltech 4 Bar MAP sensor represents a significant advancement in engine management technology, offering crucial advantages for high-performance applications. Its ability to accurately measure boost pressure in extreme conditions allows for precise fuel and ignition timing adjustments, leading to improved engine performance, fuel efficiency, and overall drivability. However, proper installation, calibration, and ongoing maintenance are essential to maximize the benefits of this powerful tool. By leveraging the capabilities of the Haltech 4 Bar MAP sensor, enthusiasts and professionals alike can unlock the full potential of their engines and achieve unparalleled performance.

Closure

Thus, we hope this article has provided valuable insights into The Haltech 4 Bar MAP Sensor: A Deeper Dive into Engine Management Precision. We thank you for taking the time to read this article. See you in our next article!