The Manifold Absolute Pressure Sensor: A Vital Component in Modern Automotive Engines

Related Articles: The Manifold Absolute Pressure Sensor: A Vital Component in Modern Automotive Engines

Introduction

In this auspicious occasion, we are delighted to delve into the intriguing topic related to The Manifold Absolute Pressure Sensor: A Vital Component in Modern Automotive Engines. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

The Manifold Absolute Pressure Sensor: A Vital Component in Modern Automotive Engines

The automotive landscape is constantly evolving, with advancements in technology driving improvements in fuel efficiency, performance, and emissions. At the heart of this evolution lies a network of sophisticated sensors that monitor and control various aspects of engine operation. One such crucial component is the Manifold Absolute Pressure (MAP) sensor. While the Volkswagen Beetle has undergone significant transformations over the years, the importance of the MAP sensor remains constant, ensuring optimal engine performance and responsiveness.

Understanding the Role of the MAP Sensor

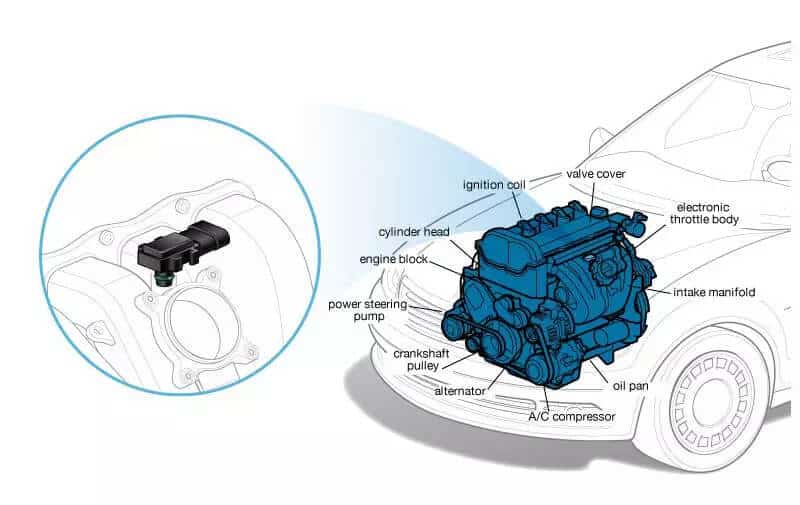

The MAP sensor plays a pivotal role in modern automotive engines, particularly those equipped with electronic fuel injection systems. Its primary function is to measure the absolute pressure within the engine’s intake manifold. This pressure, often referred to as manifold vacuum, provides valuable information about the engine’s load and the amount of air being drawn into the cylinders.

How the MAP Sensor Works

The MAP sensor is typically a small, diaphragm-based device located in the intake manifold. It operates on the principle of pressure transduction, converting the pressure signal into an electrical signal that the engine control unit (ECU) can interpret.

- Diaphragm: A flexible diaphragm separates two chambers within the sensor. One chamber is exposed to the intake manifold pressure, while the other is sealed and contains a reference pressure.

- Pressure Transduction: As the pressure in the intake manifold changes, the diaphragm flexes accordingly. This movement is detected by a sensor element, usually a piezoresistive element or a strain gauge.

- Electrical Signal: The sensor element converts the diaphragm movement into an electrical signal that corresponds to the pressure level. This signal is then transmitted to the ECU.

The Importance of the MAP Sensor

The information provided by the MAP sensor is crucial for the ECU to make informed decisions about engine operation, including:

- Fuel Injection Timing: The ECU uses the MAP sensor data to determine the precise timing of fuel injection. Higher manifold pressure indicates a heavier load, requiring more fuel to be injected.

- Air-Fuel Ratio Control: The MAP sensor data, in conjunction with other sensors like the oxygen sensor, allows the ECU to adjust the air-fuel mixture for optimal combustion.

- Ignition Timing: The ECU can adjust the ignition timing based on the manifold pressure, optimizing the combustion process for better performance and fuel economy.

- Boost Control (Turbocharged Engines): In turbocharged engines, the MAP sensor plays a vital role in regulating boost pressure, ensuring optimal performance and preventing damage to the engine.

Symptoms of a Faulty MAP Sensor

A malfunctioning MAP sensor can lead to various problems, including:

- Rough Idle: An erratic idle is a common symptom, as the ECU receives inaccurate pressure readings, causing inconsistent fuel delivery.

- Poor Acceleration: The engine may struggle to accelerate smoothly, experiencing hesitation or stumbling due to incorrect fuel-air mixtures.

- Increased Fuel Consumption: An inaccurate MAP signal can lead to a richer fuel mixture, resulting in higher fuel consumption.

- Engine Stalling: In extreme cases, a faulty MAP sensor can cause the engine to stall, particularly under heavy load or acceleration.

- Check Engine Light: The malfunctioning sensor will trigger the Check Engine Light, alerting the driver to a potential issue.

Diagnosing a Faulty MAP Sensor

Diagnosing a faulty MAP sensor often requires a combination of methods:

- Visual Inspection: Inspect the MAP sensor for physical damage, corrosion, or loose connections.

- Diagnostic Scan Tool: A scan tool can retrieve diagnostic trouble codes (DTCs) related to the MAP sensor, providing valuable insights into the problem.

- Pressure Testing: A specialized tool can be used to test the MAP sensor’s output pressure against a known reference pressure, verifying its accuracy.

- Live Data Monitoring: Using a scan tool, observe the MAP sensor’s real-time readings while the engine is running. Inconsistent or erratic readings indicate a potential issue.

Replacing a Faulty MAP Sensor

Replacing a faulty MAP sensor is a relatively straightforward process, typically involving the following steps:

- Locate the Sensor: Identify the MAP sensor, usually located in the intake manifold.

- Disconnect the Electrical Connector: Carefully disconnect the electrical connector from the sensor.

- Remove the Sensor: Depending on the vehicle, the sensor may be secured with a bolt or a clip. Carefully remove the sensor from its housing.

- Install the New Sensor: Install the new MAP sensor in the same location as the old one, ensuring proper alignment and tightness.

- Reconnect the Electrical Connector: Reconnect the electrical connector to the new sensor.

- Clear the Diagnostic Codes: After installing the new sensor, clear any related DTCs using a scan tool.

FAQs

Q: How often should a MAP sensor be replaced?

A: MAP sensors are typically quite durable and can last for many years. However, they can be affected by environmental factors, such as extreme temperatures, dirt, or vibration. If you experience any of the symptoms of a faulty sensor, it’s advisable to have it inspected by a qualified mechanic.

Q: Can I replace the MAP sensor myself?

A: While replacing a MAP sensor is generally considered a relatively simple task, it’s important to have some basic mechanical knowledge and the necessary tools. If you’re unsure, it’s always best to consult a professional mechanic.

Q: Can a faulty MAP sensor affect fuel economy?

A: Yes, a faulty MAP sensor can significantly impact fuel economy. An inaccurate pressure reading can lead to an overly rich fuel mixture, resulting in wasted fuel and reduced performance.

Q: How can I prevent a MAP sensor from failing?

A: While you can’t completely prevent a sensor from failing, you can extend its lifespan by:

- Regular Maintenance: Ensure proper air filter maintenance to prevent dirt from entering the intake manifold.

- Avoid Extreme Temperatures: Excessive heat or cold can damage the sensor.

- Protect from Moisture: Keep the sensor area clean and dry to prevent corrosion.

Tips

- Consult a Mechanic: If you suspect a faulty MAP sensor, consult a qualified mechanic for diagnosis and repair.

- Use High-Quality Replacement Parts: Always use high-quality, OE-approved replacement sensors to ensure proper functionality and longevity.

- Follow Manufacturer’s Instructions: Refer to your vehicle’s owner’s manual or a reputable repair manual for specific instructions on replacing the MAP sensor.

Conclusion

The MAP sensor is a vital component in modern automotive engines, playing a crucial role in regulating fuel injection, air-fuel mixture, and ignition timing. A functioning MAP sensor ensures optimal engine performance, fuel efficiency, and emissions control. By understanding the importance of this sensor and recognizing the signs of a malfunction, drivers can ensure their vehicles operate at peak efficiency and avoid potential problems.

Closure

Thus, we hope this article has provided valuable insights into The Manifold Absolute Pressure Sensor: A Vital Component in Modern Automotive Engines. We hope you find this article informative and beneficial. See you in our next article!