The Manifold Absolute Pressure Sensor: A Vital Component in Modern Engine Management

Related Articles: The Manifold Absolute Pressure Sensor: A Vital Component in Modern Engine Management

Introduction

In this auspicious occasion, we are delighted to delve into the intriguing topic related to The Manifold Absolute Pressure Sensor: A Vital Component in Modern Engine Management. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

The Manifold Absolute Pressure Sensor: A Vital Component in Modern Engine Management

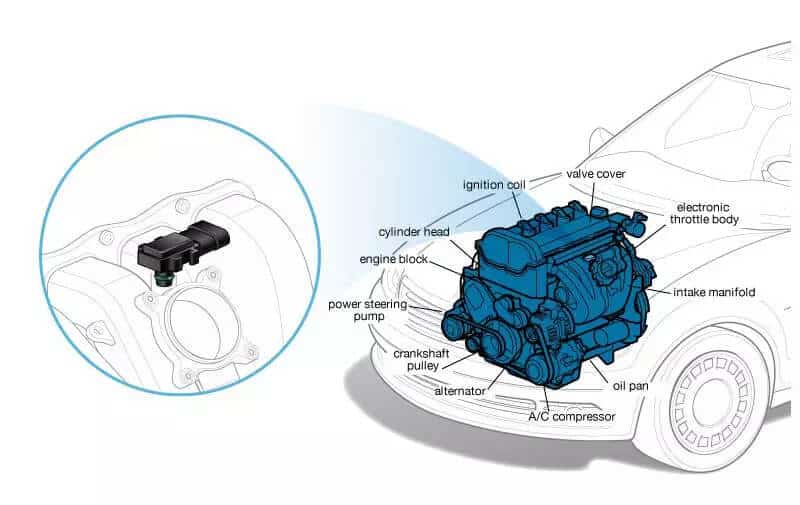

The manifold absolute pressure sensor, often referred to as the MAP sensor, is a crucial component in modern engine management systems. Its primary function is to measure the pressure within the intake manifold, providing critical information to the engine control unit (ECU) for precise fuel and ignition timing adjustments. This article delves into the workings of the MAP sensor, exploring its construction, operation, and significance in optimizing engine performance and efficiency.

The Anatomy of a MAP Sensor

A MAP sensor, in its simplest form, consists of a pressure-sensitive diaphragm, a strain gauge, and a signal conditioning circuit.

- Pressure-Sensitive Diaphragm: This diaphragm, typically made of a flexible material like silicon, is sealed at its edges and exposed to the intake manifold pressure.

- Strain Gauge: The strain gauge, bonded to the diaphragm, is a resistive element that changes its electrical resistance proportionally to the deformation of the diaphragm.

- Signal Conditioning Circuit: This circuit converts the resistance change in the strain gauge into a voltage signal that is transmitted to the ECU.

Operational Principles

The MAP sensor operates on the principle of piezoresistive transduction. As intake manifold pressure changes, the diaphragm flexes, altering the strain on the gauge. This strain, in turn, modifies the resistance of the gauge, generating a corresponding voltage change. The ECU interprets this voltage signal as a measure of the absolute pressure within the intake manifold.

Variations in MAP Sensor Design

While the fundamental principle remains constant, MAP sensor designs can differ based on specific applications and technological advancements. Some common variations include:

- Piezoresistive Sensors: The most prevalent type, utilizing a strain gauge to detect pressure-induced deformation.

- Capacitive Sensors: Employing a capacitor with plates that move in response to pressure changes, altering the capacitance and providing a pressure reading.

- Piezoelectric Sensors: Utilizing piezoelectric materials that generate an electrical charge when subjected to pressure, directly converting pressure into an electrical signal.

Importance of the MAP Sensor in Engine Management

The MAP sensor plays a pivotal role in modern engine management systems, enabling precise control over various engine parameters. Its key functions include:

- Fuel Delivery: The MAP sensor provides the ECU with information about the amount of air entering the engine. This data is crucial for calculating the appropriate fuel injection duration, ensuring an optimal air-fuel mixture for combustion.

- Ignition Timing: The MAP sensor, in conjunction with other sensors like the throttle position sensor (TPS), helps determine the optimal ignition timing for efficient combustion and reduced emissions.

- Engine Load: The MAP sensor data allows the ECU to assess the engine load, adjusting fuel delivery and ignition timing accordingly to optimize power output and fuel economy.

- Boost Pressure Control (Turbocharged Engines): In turbocharged engines, the MAP sensor monitors boost pressure, enabling the ECU to regulate the turbocharger to maintain desired boost levels.

Benefits of a Properly Functioning MAP Sensor

A properly functioning MAP sensor is essential for optimal engine performance, fuel efficiency, and emissions control.

- Improved Fuel Economy: Precise fuel delivery based on actual air intake ensures optimal combustion, reducing fuel consumption and minimizing waste.

- Enhanced Engine Performance: Accurate fuel and ignition timing adjustments optimize power output and responsiveness, leading to a smoother and more efficient driving experience.

- Reduced Emissions: Optimal combustion minimizes harmful emissions, contributing to cleaner air quality.

- Increased Engine Durability: Proper engine management, facilitated by the MAP sensor, helps prevent engine damage caused by improper fuel mixtures or detonation.

Troubleshooting a Faulty MAP Sensor

A malfunctioning MAP sensor can lead to various engine problems, including poor fuel economy, rough idling, hesitation during acceleration, and even engine misfires. Identifying a faulty MAP sensor requires careful diagnosis using a diagnostic scanner or multimeter.

Common Symptoms of a Faulty MAP Sensor:

- Check Engine Light (CEL): A malfunctioning MAP sensor will typically trigger the CEL, accompanied by a diagnostic code indicating a problem with the sensor.

- Engine Stalling: A faulty sensor may provide inaccurate readings, leading to improper fuel delivery and potential engine stalling.

- Poor Fuel Economy: An inaccurate pressure reading can result in excessive fuel consumption, as the ECU may overcompensate for the perceived air intake.

- Rough Idling: A faulty sensor may cause the engine to idle erratically or stall due to improper fuel and ignition timing.

- Hesitation During Acceleration: A faulty sensor can lead to hesitation or stumbling during acceleration, as the ECU struggles to adjust fuel delivery accurately.

FAQs about the MAP Sensor

Q: What is the difference between a MAP sensor and a MAF sensor?

A: Both MAP and MAF sensors play crucial roles in engine management, but they measure different parameters.

- MAP sensor: Measures the absolute pressure within the intake manifold, providing information about the air density.

- MAF sensor: Measures the mass airflow entering the engine, providing information about the actual amount of air flowing into the engine.

Q: Can I replace a MAP sensor myself?

A: Replacing a MAP sensor is generally a straightforward task. However, it is essential to consult the vehicle’s repair manual for specific instructions and ensure proper tools and safety precautions are taken.

Q: How often should I replace a MAP sensor?

A: MAP sensors are designed to be durable and typically last for the lifespan of the vehicle. However, factors like environmental conditions, engine wear, and exposure to extreme temperatures can affect their lifespan. It is generally recommended to replace a MAP sensor if it malfunctions or exhibits signs of failure.

Q: Can a faulty MAP sensor cause engine damage?

A: While a faulty MAP sensor will not directly cause physical damage to the engine, it can lead to improper fuel delivery and ignition timing, potentially causing engine knocking or detonation, which can damage engine components over time.

Tips for Maintaining a MAP Sensor

- Regular Engine Maintenance: Routine maintenance, including air filter replacement and engine tune-ups, helps ensure optimal engine performance and minimizes stress on the MAP sensor.

- Avoid Exposure to Extreme Conditions: Excessive heat or cold can affect the sensor’s performance. Protect the engine compartment from extreme temperatures.

- Proper Cleaning: If the MAP sensor becomes dirty or contaminated, it can affect its accuracy. Consult the vehicle’s repair manual for cleaning instructions.

- Professional Diagnosis: If you suspect a MAP sensor malfunction, seek professional diagnosis and repair to ensure proper functioning.

Conclusion

The MAP sensor is an indispensable component in modern engine management systems, playing a crucial role in optimizing fuel efficiency, engine performance, and emissions control. Understanding its operation, benefits, and potential problems is essential for maintaining a healthy and efficient engine. Regular maintenance, proper diagnosis, and prompt replacement when necessary can ensure the longevity and optimal performance of your vehicle.

Closure

Thus, we hope this article has provided valuable insights into The Manifold Absolute Pressure Sensor: A Vital Component in Modern Engine Management. We appreciate your attention to our article. See you in our next article!