The Manifold Absolute Pressure Sensor: A Vital Component in Modern Engine Management

Related Articles: The Manifold Absolute Pressure Sensor: A Vital Component in Modern Engine Management

Introduction

With enthusiasm, let’s navigate through the intriguing topic related to The Manifold Absolute Pressure Sensor: A Vital Component in Modern Engine Management. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

The Manifold Absolute Pressure Sensor: A Vital Component in Modern Engine Management

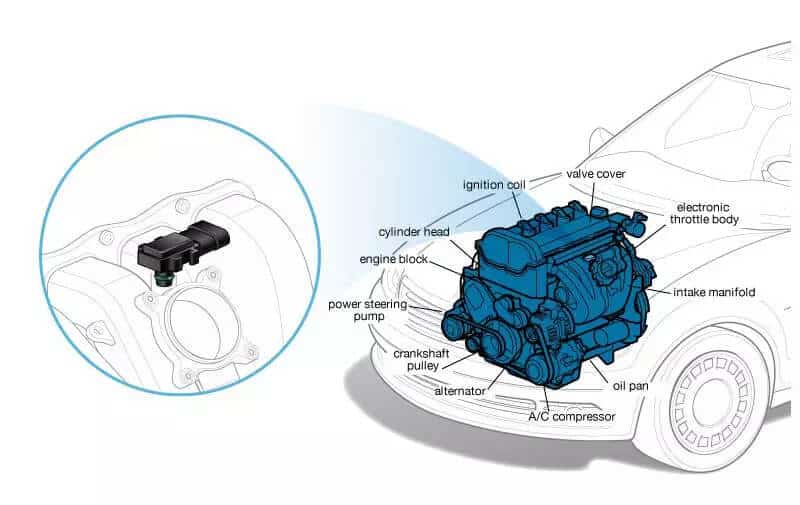

The manifold absolute pressure (MAP) sensor, a critical element in modern internal combustion engine management systems, plays a pivotal role in optimizing fuel efficiency and reducing emissions. This article delves into the workings, function, and significance of the MAP sensor, providing a comprehensive understanding of its role in ensuring optimal engine performance.

Understanding the MAP Sensor’s Function

The MAP sensor is essentially a pressure transducer, tasked with measuring the absolute pressure within the engine’s intake manifold. This pressure, a direct indicator of the air density entering the cylinders, is a crucial parameter for the engine control unit (ECU) to calculate the precise amount of fuel required for combustion.

The Inner Workings of the MAP Sensor

MAP sensors typically employ a diaphragm-based design, where a thin, flexible diaphragm separates a sealed chamber from the intake manifold. When engine vacuum draws air into the manifold, the diaphragm deflects in response to the pressure difference. This deflection is converted into an electrical signal by a sensor element, usually a strain gauge or a piezoresistive element, which changes its resistance proportionally to the pressure variation.

Types of MAP Sensors

MAP sensors can be broadly categorized into two types:

-

Piezoresistive MAP Sensors: These sensors utilize a piezoresistive element, typically a semiconductor material, whose resistance changes with pressure. This change in resistance is measured and converted into a voltage signal by the ECU.

-

Strain Gauge MAP Sensors: These sensors employ a strain gauge, a thin, resistive wire bonded to the diaphragm. As the diaphragm deflects, the strain gauge experiences a change in resistance, which is then measured and converted into a voltage signal by the ECU.

The MAP Sensor’s Role in Engine Management

The MAP sensor plays a critical role in various engine management functions, including:

-

Fuel Injection Control: The ECU uses the MAP sensor readings to determine the amount of fuel injected into the cylinders. By knowing the air density, the ECU can calculate the precise fuel-to-air ratio required for optimal combustion.

-

Spark Timing Control: The MAP sensor also contributes to optimizing spark timing. By analyzing the manifold pressure, the ECU can adjust the ignition timing to ensure efficient combustion under various engine load and speed conditions.

-

Emissions Control: The MAP sensor plays a crucial role in controlling emissions. By providing accurate information about air density, the ECU can fine-tune the fuel-air mixture to minimize harmful emissions like carbon monoxide, hydrocarbons, and nitrogen oxides.

-

Boost Pressure Control (Turbocharged Engines): In turbocharged engines, the MAP sensor is vital for monitoring and controlling boost pressure. It provides the ECU with real-time data on the pressure generated by the turbocharger, allowing for precise control of boost levels and optimal engine performance.

Importance of the MAP Sensor

The MAP sensor’s contribution to engine performance is significant. It enables the ECU to:

-

Optimize Fuel Efficiency: By accurately calculating the required fuel amount, the MAP sensor helps reduce fuel consumption and improve overall fuel economy.

-

Minimize Emissions: Precise control over the fuel-air mixture based on MAP sensor readings contributes to lower emissions and reduced environmental impact.

-

Enhance Engine Performance: By optimizing fuel injection and spark timing, the MAP sensor ensures smooth engine operation, optimal power delivery, and a more responsive throttle response.

Diagnosing MAP Sensor Issues

A malfunctioning MAP sensor can lead to a variety of engine problems, including:

-

Rough Idle: An inaccurate MAP reading can disrupt the fuel-air mixture, resulting in an uneven idle.

-

Stalling: A faulty MAP sensor might cause the ECU to miscalculate the fuel requirements, leading to engine stalling.

-

Poor Acceleration: Incorrect fuel-air ratio due to a malfunctioning sensor can result in sluggish acceleration and reduced power output.

-

Increased Fuel Consumption: An inaccurate MAP reading can cause the engine to run rich, resulting in higher fuel consumption.

-

Check Engine Light: A malfunctioning MAP sensor will often trigger the check engine light, indicating a problem requiring attention.

FAQs Regarding the MAP Sensor

Q: How often should a MAP sensor be replaced?

A: MAP sensors are generally quite reliable and can last for many years. However, their lifespan can be affected by factors like exposure to extreme temperatures, dirt, and vibrations. If you experience symptoms of a failing MAP sensor, it is recommended to have it inspected and potentially replaced.

Q: Can I clean a MAP sensor?

A: While cleaning a MAP sensor might seem tempting, it is generally not recommended. The sensor is a delicate component, and improper cleaning can damage it. If you suspect contamination, it is best to replace the sensor with a new one.

Q: Can I test a MAP sensor myself?

A: While there are DIY methods for testing a MAP sensor, it is advisable to have it checked by a qualified mechanic. They have specialized tools and knowledge to accurately diagnose and troubleshoot sensor problems.

Q: How do I know if my MAP sensor is bad?

A: The symptoms of a failing MAP sensor can be similar to other engine issues. A mechanic can use diagnostic tools to assess the sensor’s output and determine if it is malfunctioning.

Tips for Maintaining a MAP Sensor

-

Regular Maintenance: Ensure regular engine maintenance, including air filter replacement and general cleaning, to minimize dust and debris accumulation around the MAP sensor.

-

Avoid Harsh Conditions: Protect the MAP sensor from extreme temperatures, excessive vibrations, and corrosive substances.

-

Professional Inspection: If you suspect a MAP sensor issue, consult a qualified mechanic for diagnosis and repair.

Conclusion

The MAP sensor is an essential component in modern engine management systems, playing a crucial role in optimizing fuel efficiency, reducing emissions, and enhancing engine performance. Its accurate measurement of manifold pressure provides the ECU with vital information for calculating the precise fuel-air mixture, spark timing, and other critical parameters. By understanding the function and importance of the MAP sensor, drivers can better appreciate its contribution to a smooth, efficient, and environmentally friendly driving experience.

Closure

Thus, we hope this article has provided valuable insights into The Manifold Absolute Pressure Sensor: A Vital Component in Modern Engine Management. We hope you find this article informative and beneficial. See you in our next article!