The Manifold Absolute Pressure Sensor: A Vital Component in Modern Engine Management

Related Articles: The Manifold Absolute Pressure Sensor: A Vital Component in Modern Engine Management

Introduction

With enthusiasm, let’s navigate through the intriguing topic related to The Manifold Absolute Pressure Sensor: A Vital Component in Modern Engine Management. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

The Manifold Absolute Pressure Sensor: A Vital Component in Modern Engine Management

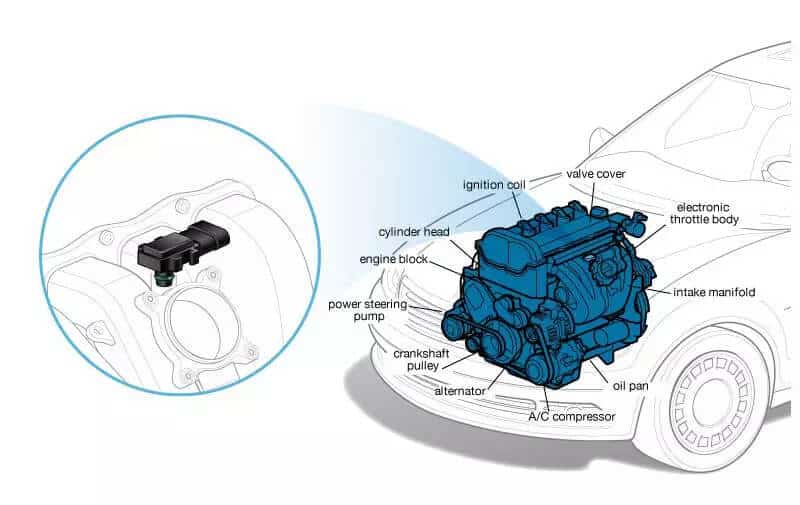

The manifold absolute pressure sensor, commonly known as the MAP sensor, plays a crucial role in modern internal combustion engines by providing the engine control unit (ECU) with vital information regarding engine load. This information allows the ECU to precisely control fuel injection, ignition timing, and other parameters, optimizing engine performance, fuel efficiency, and emissions.

Understanding the Working Principle of a MAP Sensor

The MAP sensor is essentially a pressure transducer, converting the pressure within the engine’s intake manifold into an electrical signal that the ECU can interpret. The principle behind its operation relies on the relationship between pressure and resistance.

1. Sensing the Intake Manifold Pressure:

The MAP sensor is typically mounted on the intake manifold, directly exposed to the pressure fluctuations within it. This pressure, known as manifold absolute pressure (MAP), represents the load placed on the engine. Higher MAP values indicate a greater load, while lower values signify a lighter load.

2. Converting Pressure to Resistance:

Inside the MAP sensor, a diaphragm is exposed to the intake manifold pressure. This diaphragm is connected to a variable resistor, which changes its resistance based on the pressure applied. As the pressure increases, the diaphragm deflects, causing the resistance to decrease. Conversely, a decrease in pressure results in an increase in resistance.

3. Generating an Electrical Signal:

The variable resistor is part of an electrical circuit, typically a Wheatstone bridge configuration. The changing resistance within the bridge alters the voltage across the circuit, generating an electrical signal that is proportional to the intake manifold pressure.

4. Transmitting the Signal to the ECU:

The electrical signal from the MAP sensor is transmitted to the ECU. The ECU interprets this signal, converting it back into pressure readings. This information is then utilized to adjust various engine parameters.

The Importance of the MAP Sensor in Engine Management

The MAP sensor plays a pivotal role in several key aspects of engine management:

1. Fuel Injection Control:

The ECU uses the MAP sensor readings to determine the amount of fuel injected into the engine cylinders. Higher MAP values indicate a greater need for fuel, while lower values suggest a reduced fuel requirement. This ensures optimal air-fuel mixture for efficient combustion and reduced emissions.

2. Ignition Timing Control:

The ECU also utilizes MAP sensor data to adjust ignition timing. Higher MAP values often require a slightly delayed ignition timing to prevent knocking or detonation, while lower values may allow for earlier ignition timing to improve performance.

3. Throttle Position Control:

Some modern vehicles utilize the MAP sensor in conjunction with a throttle position sensor (TPS) to provide a more accurate representation of engine load. This allows for finer control of throttle response and engine performance.

4. Emissions Control:

The MAP sensor plays a vital role in emissions control systems. By providing accurate information about engine load, it enables the ECU to adjust the air-fuel ratio and other parameters to minimize harmful emissions.

5. Boost Pressure Control:

In turbocharged engines, the MAP sensor is essential for monitoring and controlling boost pressure. This ensures optimal performance and prevents overboosting, which can damage the engine.

FAQs about MAP Sensors

1. How Often Should a MAP Sensor Be Replaced?

MAP sensors are generally quite durable and can last for the life of the vehicle. However, they can become faulty due to environmental factors like dirt, oil, or moisture. If the sensor is suspected of malfunctioning, it should be replaced as soon as possible.

2. What are the Symptoms of a Faulty MAP Sensor?

A malfunctioning MAP sensor can lead to several symptoms, including:

- Poor fuel economy

- Rough idling

- Hesitation or stuttering during acceleration

- Difficulty starting

- Engine stalling

- Check engine light illumination

3. Can a Faulty MAP Sensor Be Repaired?

MAP sensors are typically not repairable. If a sensor is malfunctioning, it needs to be replaced with a new one.

4. How Can I Test a MAP Sensor?

Testing a MAP sensor requires specialized equipment and knowledge. It’s best to consult a qualified mechanic for testing and diagnosis.

Tips for Maintaining a MAP Sensor

- Avoid exposing the MAP sensor to excessive heat or moisture.

- Ensure that the intake manifold is properly sealed to prevent leaks.

- Regularly inspect the MAP sensor for signs of damage or contamination.

- Use high-quality fuel and air filters to prevent debris from reaching the sensor.

Conclusion

The MAP sensor plays a crucial role in modern engine management systems. By providing accurate information about engine load, it enables the ECU to optimize fuel injection, ignition timing, and other parameters, leading to improved performance, fuel efficiency, and reduced emissions. Understanding the working principle of the MAP sensor is essential for diagnosing engine problems and ensuring optimal vehicle performance.

Closure

Thus, we hope this article has provided valuable insights into The Manifold Absolute Pressure Sensor: A Vital Component in Modern Engine Management. We hope you find this article informative and beneficial. See you in our next article!