The Manifold Absolute Pressure Sensor: Understanding and Troubleshooting a Critical Engine Component

Related Articles: The Manifold Absolute Pressure Sensor: Understanding and Troubleshooting a Critical Engine Component

Introduction

With enthusiasm, let’s navigate through the intriguing topic related to The Manifold Absolute Pressure Sensor: Understanding and Troubleshooting a Critical Engine Component. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

The Manifold Absolute Pressure Sensor: Understanding and Troubleshooting a Critical Engine Component

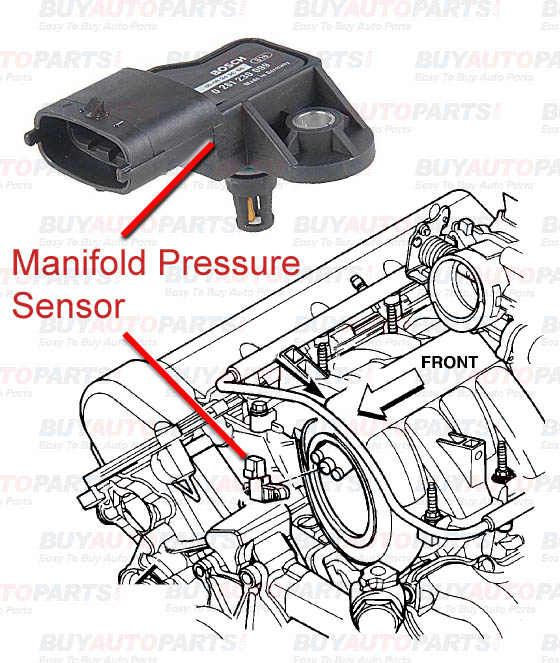

The manifold absolute pressure sensor, commonly known as the MAP sensor, plays a crucial role in the efficient operation of modern gasoline engines. This sensor, located in the intake manifold, measures the pressure of the air entering the engine, providing vital information to the engine control unit (ECU). This data is then used to calculate the amount of fuel injected, ultimately impacting the engine’s power, fuel efficiency, and emissions.

Understanding the Role of the MAP Sensor

The MAP sensor is a critical component in modern engine management systems. Its primary function is to measure the absolute pressure of the air in the intake manifold. This pressure fluctuates based on engine load and speed, providing valuable information to the ECU.

Here’s how the MAP sensor contributes to optimal engine performance:

- Fuel Injection Control: The ECU uses the MAP sensor reading to determine the appropriate amount of fuel to inject into the engine. This ensures a precise air-fuel mixture, essential for efficient combustion and power output.

- Engine Timing: The MAP sensor reading also influences the ignition timing, optimizing the combustion process for maximum efficiency and reduced emissions.

- Boost Control: In turbocharged engines, the MAP sensor plays a crucial role in regulating boost pressure, ensuring optimal performance and preventing damage to the engine.

- Emissions Control: By optimizing fuel injection and ignition timing, the MAP sensor indirectly contributes to reducing harmful emissions from the engine.

Recognizing the Signs of a Faulty MAP Sensor

A faulty MAP sensor can lead to various engine problems, including:

- Rough Idle: A malfunctioning MAP sensor can cause the engine to idle unevenly or stall, as the ECU receives inaccurate information about the air pressure.

- Reduced Power: The engine may experience a noticeable loss of power, as the ECU struggles to determine the correct fuel injection amount.

- Increased Fuel Consumption: An inaccurate MAP sensor reading can lead to the engine running rich, resulting in higher fuel consumption.

- Check Engine Light: A faulty MAP sensor will often trigger the check engine light, alerting the driver to a potential problem.

- Poor Acceleration: The engine may hesitate or struggle to accelerate smoothly due to the ECU receiving incorrect information about the air pressure.

Troubleshooting a Potential MAP Sensor Issue

While a malfunctioning MAP sensor can lead to various engine problems, it’s important to note that these symptoms can also be caused by other issues. A thorough diagnosis is essential to pinpoint the root cause of the problem.

Here’s a step-by-step approach to troubleshoot a potential MAP sensor issue:

- Check the Check Engine Light: A check engine light accompanied by a specific code related to the MAP sensor suggests a potential issue.

- Visual Inspection: Inspect the MAP sensor for any visible damage, such as cracks, loose connections, or corrosion.

- Vacuum Leak Test: Conduct a vacuum leak test to ensure there are no leaks in the intake manifold, which can affect the MAP sensor readings.

- Voltage Test: Use a multimeter to measure the voltage output from the MAP sensor under different engine conditions. This can help determine if the sensor is providing accurate readings.

- Pressure Test: If possible, connect a pressure gauge to the MAP sensor port and compare the readings to the manufacturer’s specifications. This can help identify any discrepancies in sensor performance.

Tips for Maintaining a Healthy MAP Sensor

While the MAP sensor is generally a robust component, proper maintenance can help ensure its longevity and optimal performance:

- Regular Engine Maintenance: Ensure regular engine maintenance, including air filter replacement, to prevent debris from accumulating in the intake manifold and potentially damaging the MAP sensor.

- Avoid Excessive Engine Modifications: Avoid making significant modifications to the engine, such as adding a turbocharger or supercharger, without consulting a professional. These modifications can put excessive stress on the MAP sensor.

- Use Quality Fuel: Using high-quality fuel can help prevent the build-up of deposits in the intake manifold, which can affect the MAP sensor’s performance.

Conclusion

The MAP sensor is an essential component in modern gasoline engines, playing a crucial role in optimizing engine performance, fuel efficiency, and emissions. Understanding its function and the potential signs of a malfunction can help drivers identify and address any problems early on. Regular maintenance and proper troubleshooting can help ensure the longevity and optimal performance of this critical engine component.

Closure

Thus, we hope this article has provided valuable insights into The Manifold Absolute Pressure Sensor: Understanding and Troubleshooting a Critical Engine Component. We hope you find this article informative and beneficial. See you in our next article!