The Significance of Toilet Performance Testing in 2011: A Comprehensive Overview

Related Articles: The Significance of Toilet Performance Testing in 2011: A Comprehensive Overview

Introduction

With enthusiasm, let’s navigate through the intriguing topic related to The Significance of Toilet Performance Testing in 2011: A Comprehensive Overview. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

The Significance of Toilet Performance Testing in 2011: A Comprehensive Overview

The year 2011 marked a pivotal point in the evolution of toilet technology, with the introduction of stringent performance testing standards aimed at improving water efficiency and reducing environmental impact. This shift in focus significantly impacted the design and manufacturing of toilets, leading to a new era of innovation and sustainability.

Understanding the Need for Toilet Performance Testing

Prior to 2011, the prevalent toilet designs often consumed excessive amounts of water per flush, contributing to water scarcity and putting a strain on wastewater treatment infrastructure. Recognizing the need for a more responsible approach, regulatory bodies and industry stakeholders began advocating for standardized testing procedures to measure and compare toilet performance.

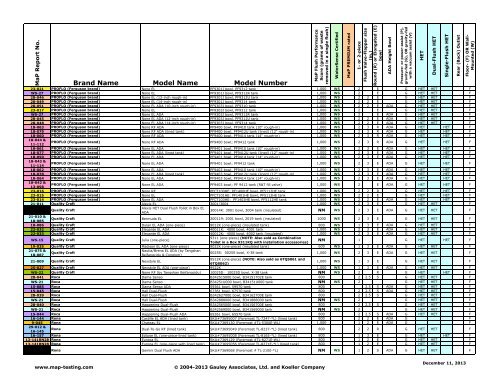

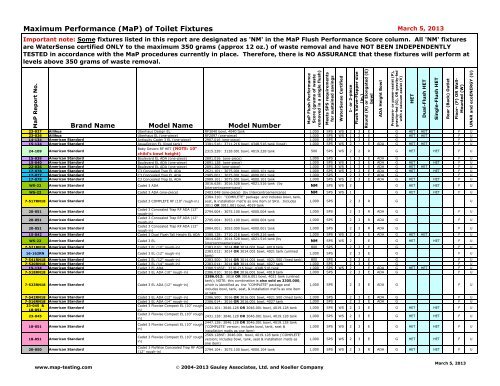

MAP Testing: A Benchmark for Efficiency and Performance

The "Maximum Performance (MAP) Test" emerged as a crucial tool in this transformation. This standardized test method, developed by the WaterSense program, evaluates a toilet’s ability to effectively remove waste while minimizing water usage. The test involves flushing a specific volume of water and measuring the amount of water required to achieve a clean flush.

Key Parameters Evaluated in MAP Testing

The MAP Test evaluates several critical parameters, including:

- Maximum Performance (MAP) Value: This metric represents the maximum volume of water a toilet can effectively flush, measured in gallons per flush (gpf).

- Water Consumption: This parameter measures the total amount of water used for each flush, providing insight into the toilet’s overall water efficiency.

- Bowl Cleanliness: The test assesses the effectiveness of the flush in removing waste and leaving the bowl clean.

- Solid Waste Removal: This parameter evaluates the toilet’s ability to remove solid waste effectively.

- Liquid Waste Removal: The test measures the toilet’s ability to remove liquid waste efficiently.

Benefits of MAP Testing for Consumers and the Environment

MAP testing brought numerous benefits to consumers and the environment:

- Water Conservation: The focus on water efficiency led to the development of toilets using significantly less water per flush, reducing overall water consumption and minimizing strain on water resources.

- Cost Savings: Water-efficient toilets resulted in lower water bills for consumers, translating into significant cost savings over time.

- Environmental Sustainability: Reduced water consumption minimized the environmental impact associated with water treatment and distribution, contributing to a more sustainable approach to sanitation.

- Improved Toilet Performance: Standardized testing led to the development of innovative designs and technologies that improved toilet performance, ensuring efficient waste removal and a cleaner experience.

The Impact of MAP Testing on Toilet Design and Manufacturing

The implementation of MAP testing significantly impacted the design and manufacturing of toilets:

- Focus on Efficiency: Manufacturers shifted their focus towards developing toilets that met the stringent water efficiency standards established by the MAP test.

- Innovation in Design: The need to optimize water usage led to innovative design features, such as dual-flush systems, low-flow technology, and improved bowl geometry.

- Increased Competition: The focus on performance and efficiency fostered competition among manufacturers, driving innovation and the development of more efficient and effective toilets.

Frequently Asked Questions (FAQs) about MAP Testing

Q: What is the difference between a standard flush toilet and a MAP-tested toilet?

A: MAP-tested toilets are designed and manufactured to meet specific performance standards, ensuring efficient waste removal while using significantly less water per flush compared to standard flush toilets.

Q: How does MAP testing ensure toilet efficiency?

A: The MAP Test evaluates the toilet’s ability to remove waste effectively while minimizing water usage. This standardized testing process ensures that toilets meet specific performance criteria and are deemed water-efficient.

Q: What are the benefits of using a MAP-tested toilet?

A: MAP-tested toilets offer numerous benefits, including water conservation, cost savings, environmental sustainability, and improved performance.

Q: How can I identify a MAP-tested toilet?

A: Look for the WaterSense label on the toilet, indicating that it has been certified to meet the stringent performance standards established by the MAP Test.

Tips for Choosing a MAP-Tested Toilet

- Consider the WaterSense Label: Look for the WaterSense label, a reliable indicator of a toilet’s performance and water efficiency.

- Check the MAP Value: Compare the MAP value of different toilets to determine their water consumption and flushing performance.

- Read Reviews: Consult online reviews and consumer reports to gain insights into the performance and reliability of specific toilet models.

- Factor in Installation Costs: Consider the cost of installation, as some models may require specialized fittings or modifications.

Conclusion

The introduction of MAP testing in 2011 represented a significant step forward in the evolution of toilet technology. This standardized testing method transformed the industry, leading to the development of water-efficient toilets that significantly reduced water consumption and environmental impact. By focusing on performance and efficiency, MAP testing has played a crucial role in promoting sustainable sanitation practices and contributing to a more environmentally conscious future.

Closure

Thus, we hope this article has provided valuable insights into The Significance of Toilet Performance Testing in 2011: A Comprehensive Overview. We thank you for taking the time to read this article. See you in our next article!