The Unsung Hero of Engine Management: Delving into the Role of the Manifold Absolute Pressure Sensor

Related Articles: The Unsung Hero of Engine Management: Delving into the Role of the Manifold Absolute Pressure Sensor

Introduction

In this auspicious occasion, we are delighted to delve into the intriguing topic related to The Unsung Hero of Engine Management: Delving into the Role of the Manifold Absolute Pressure Sensor. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

The Unsung Hero of Engine Management: Delving into the Role of the Manifold Absolute Pressure Sensor

The modern internal combustion engine, a marvel of engineering, relies on a complex interplay of systems to deliver optimal performance. Among these, the manifold absolute pressure (MAP) sensor plays a crucial role, silently orchestrating fuel delivery and ignition timing for smooth and efficient operation. This article delves into the intricate workings of the MAP sensor, elucidating its vital function in the engine management system and highlighting its impact on vehicle performance, fuel economy, and emissions.

Understanding the MAP Sensor’s Role

The MAP sensor, a key component of the engine control unit (ECU), measures the absolute pressure within the engine’s intake manifold. This pressure, which fluctuates based on engine speed and load, provides the ECU with critical information about the volume of air entering the cylinders. This information is essential for the ECU to accurately calculate the amount of fuel required for combustion, ensuring a precise air-fuel mixture.

How the MAP Sensor Works

The MAP sensor, typically a small, diaphragm-based device, operates on the principle of pressure sensing. It contains a diaphragm that flexes in response to changes in manifold pressure. This flexing alters the resistance of a strain gauge, which is integrated into the sensor. The ECU interprets the change in resistance as a change in manifold pressure, translating it into an electrical signal.

The Importance of Accurate Pressure Readings

The accuracy of the MAP sensor’s readings is paramount for engine performance. An inaccurate pressure reading can lead to a variety of issues, including:

- Poor Fuel Economy: An incorrect air-fuel mixture can result in excessive fuel consumption, impacting the vehicle’s overall efficiency.

- Reduced Engine Power: A lean air-fuel mixture, caused by insufficient fuel delivery, can lead to a decrease in engine power and sluggish acceleration.

- Rough Running and Stalling: An overly rich air-fuel mixture, caused by excessive fuel delivery, can lead to engine misfires, rough idling, and even stalling.

- Increased Emissions: Incorrect air-fuel ratios can result in higher emissions of harmful pollutants, such as carbon monoxide, hydrocarbons, and nitrogen oxides.

The MAP Sensor’s Impact on Engine Management

The MAP sensor’s readings are used by the ECU to control several crucial engine functions, including:

- Fuel Injection Timing: The ECU uses the MAP sensor readings to determine the precise timing of fuel injection, ensuring the correct amount of fuel is delivered at the optimal moment for combustion.

- Ignition Timing: The MAP sensor readings are also used to adjust the timing of ignition, optimizing the combustion process for maximum efficiency and power.

- Air-Fuel Ratio Control: The MAP sensor’s readings are instrumental in maintaining the optimal air-fuel ratio for combustion, minimizing emissions and maximizing fuel efficiency.

- Variable Valve Timing: In some engines equipped with variable valve timing (VVT) systems, the MAP sensor readings are used to control the timing of valve opening and closing, further optimizing engine performance.

Common Symptoms of a Faulty MAP Sensor

A faulty MAP sensor can manifest in various symptoms, including:

- Check Engine Light (CEL): The ECU will typically illuminate the CEL if it detects a malfunctioning MAP sensor.

- Engine Stalling: A faulty sensor may provide inaccurate readings, leading to an incorrect air-fuel mixture and potential engine stalling.

- Rough Idling: A faulty sensor can cause fluctuations in engine speed, resulting in a rough idle.

- Reduced Power: An inaccurate air-fuel mixture can lead to a loss of power and sluggish acceleration.

- Increased Fuel Consumption: A faulty sensor may lead to an over-rich air-fuel mixture, resulting in increased fuel consumption.

- Erratic Engine Performance: The engine may exhibit erratic behavior, such as surging or hesitation, due to inconsistent air-fuel ratios.

Troubleshooting a Faulty MAP Sensor

Diagnosing a faulty MAP sensor typically involves a combination of visual inspection, diagnostic testing, and pressure measurements.

- Visual Inspection: Check the MAP sensor for any signs of damage, such as cracks, leaks, or corrosion.

- Diagnostic Testing: Use an OBD-II scanner to retrieve any error codes related to the MAP sensor.

- Pressure Measurement: A pressure gauge can be used to measure the actual manifold pressure and compare it to the readings provided by the MAP sensor.

Replacing a Faulty MAP Sensor

Replacing a faulty MAP sensor is typically a straightforward procedure:

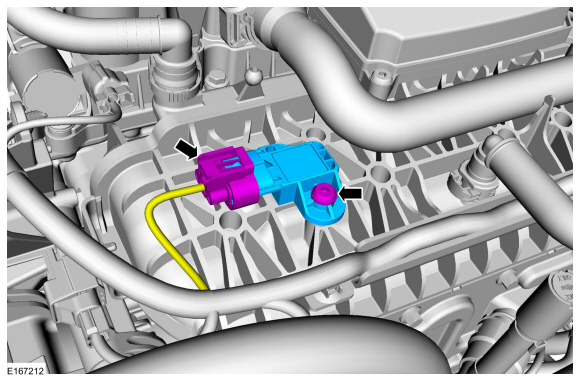

- Locate the MAP Sensor: The MAP sensor is usually located on the intake manifold or near the throttle body.

- Disconnect the Electrical Connector: Disconnect the electrical connector leading to the sensor.

- Remove the Sensor: Remove the sensor from its mounting location.

- Install the New Sensor: Install the new sensor in the same location, ensuring a tight connection.

- Reconnect the Electrical Connector: Reconnect the electrical connector to the new sensor.

- Clear Error Codes: Use an OBD-II scanner to clear any error codes related to the MAP sensor.

FAQs about the MAP Sensor

Q: What is the difference between a MAP sensor and a MAF sensor?

A: The MAP sensor measures manifold absolute pressure, which is a function of engine load and speed. The MAF sensor, on the other hand, measures the mass airflow rate entering the engine. While both sensors play a crucial role in engine management, they provide different types of information to the ECU.

Q: How often should a MAP sensor be replaced?

A: MAP sensors are typically designed for long-term durability. However, they can become faulty over time due to wear and tear, exposure to harsh conditions, or contamination. If you suspect a malfunctioning MAP sensor, it’s advisable to have it inspected and replaced as needed.

Q: Can a faulty MAP sensor cause a catalytic converter to fail?

A: Yes, a faulty MAP sensor can indirectly contribute to catalytic converter failure. An inaccurate air-fuel mixture can lead to increased emissions, which can overload the catalytic converter and cause it to fail prematurely.

Tips for Maintaining the MAP Sensor

- Regular Maintenance: Ensure regular engine maintenance, including air filter replacement and intake manifold cleaning, to minimize contamination and ensure optimal sensor performance.

- Avoid Harsh Environments: Minimize exposure to extreme temperatures, corrosive chemicals, and excessive vibration, as these can damage the sensor.

- Use Quality Fuel: Use high-quality fuel to minimize the risk of sensor contamination.

- Professional Inspection: Have the MAP sensor inspected by a qualified mechanic during routine maintenance checks.

Conclusion

The MAP sensor, though often overlooked, plays a critical role in modern engine management. By providing the ECU with accurate information about manifold pressure, it enables precise control over fuel delivery and ignition timing, resulting in optimal engine performance, fuel efficiency, and reduced emissions. Recognizing the significance of the MAP sensor and understanding its function can help drivers maintain their vehicles effectively, ensuring smooth operation and long-term reliability.

Closure

Thus, we hope this article has provided valuable insights into The Unsung Hero of Engine Management: Delving into the Role of the Manifold Absolute Pressure Sensor. We thank you for taking the time to read this article. See you in our next article!