The Unsung Hero of Engine Performance: The MAP Sensor Grommet

Related Articles: The Unsung Hero of Engine Performance: The MAP Sensor Grommet

Introduction

With great pleasure, we will explore the intriguing topic related to The Unsung Hero of Engine Performance: The MAP Sensor Grommet. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

The Unsung Hero of Engine Performance: The MAP Sensor Grommet

In the intricate world of automotive engineering, every component plays a crucial role in ensuring smooth and efficient operation. While the spotlight often shines on high-profile parts like the engine or transmission, there are numerous unsung heroes that quietly contribute to the overall performance and longevity of a vehicle. One such unsung hero is the manifold absolute pressure (MAP) sensor grommet, a seemingly insignificant component that holds immense importance in maintaining the integrity of the engine’s crucial sensor.

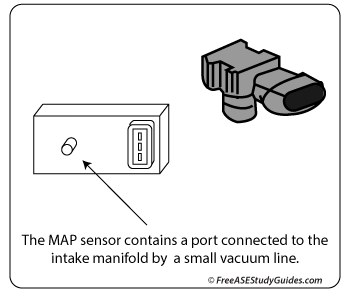

The MAP sensor, a critical component in modern engine management systems, measures the pressure within the intake manifold. This information is then relayed to the engine control unit (ECU), which uses it to determine the appropriate amount of fuel to inject and the timing of ignition, ultimately influencing the engine’s performance and fuel efficiency.

The MAP sensor grommet acts as a protective barrier, shielding the MAP sensor from the harsh environment of the engine bay. It serves several critical functions:

1. Sealing and Protection: The grommet creates a tight seal around the MAP sensor, preventing contaminants like dirt, debris, and moisture from entering the sensor housing. This is crucial for maintaining the sensor’s accuracy and preventing malfunctions.

2. Vibration Dampening: The engine bay is a vibrantly dynamic environment, with constant movement and vibrations. The grommet acts as a shock absorber, mitigating the impact of these vibrations on the MAP sensor, thus protecting its delicate internal components from damage.

3. Electrical Insulation: The MAP sensor grommet also provides electrical insulation, ensuring that the sensor’s electrical connections are protected from short circuits and other electrical hazards. This is essential for maintaining the integrity of the sensor’s signal transmission to the ECU.

4. Environmental Protection: The grommet serves as a barrier against extreme temperatures, both hot and cold. It prevents heat from the engine from directly affecting the sensor, ensuring its accurate operation even under challenging conditions.

The Importance of a Healthy MAP Sensor Grommet:

A worn-out or damaged MAP sensor grommet can lead to a cascade of problems, significantly impacting the engine’s performance and fuel economy. Here are some common issues that can arise:

-

Inaccurate Readings: A compromised grommet can allow contaminants to enter the sensor housing, affecting its ability to accurately measure manifold pressure. This results in inaccurate data being sent to the ECU, leading to improper fuel delivery and ignition timing.

-

Engine Misfire: Inaccurate fuel delivery and ignition timing can lead to engine misfires, causing rough idle, stalling, and reduced power output.

-

Increased Fuel Consumption: The engine’s inability to operate efficiently due to inaccurate sensor readings can result in increased fuel consumption, impacting the vehicle’s overall fuel economy.

-

Check Engine Light: The ECU will often detect a faulty MAP sensor and illuminate the check engine light, prompting a diagnostic check to identify the root cause.

-

Premature Sensor Failure: A damaged grommet can accelerate the wear and tear on the MAP sensor, leading to premature sensor failure and the need for costly replacements.

Identifying a Damaged MAP Sensor Grommet:

While a damaged grommet may not always be immediately obvious, there are several telltale signs that can indicate a potential issue:

- Visible Cracks or Tears: Inspect the grommet visually for any cracks, tears, or signs of wear and tear.

- Loose or Detached Grommet: Check if the grommet is securely attached to the MAP sensor and the intake manifold.

- Presence of Contaminants: Look for any signs of dirt, debris, or moisture around the sensor and the grommet.

- Engine Performance Issues: If you experience any of the symptoms mentioned earlier, such as engine misfires, rough idle, or increased fuel consumption, a damaged MAP sensor grommet could be a contributing factor.

Replacing a Damaged MAP Sensor Grommet:

Replacing a damaged MAP sensor grommet is a relatively straightforward process that can be accomplished by a skilled mechanic or a DIY enthusiast with basic mechanical knowledge. However, it’s crucial to use a genuine OEM (Original Equipment Manufacturer) grommet or a high-quality aftermarket replacement to ensure optimal performance and longevity.

FAQs about MAP Sensor Grommets:

Q: How often should I inspect the MAP sensor grommet?

A: Regularly inspecting the grommet during routine maintenance checks, such as oil changes or tire rotations, is recommended. However, if you notice any signs of engine performance issues, a closer inspection is warranted.

Q: Can I use a generic grommet for the MAP sensor?

A: While generic grommets might seem like a cost-effective solution, it’s highly recommended to use a genuine OEM or a reputable aftermarket replacement. Generic grommets may not be designed to the exact specifications of the original part, potentially leading to issues with sealing, vibration dampening, and electrical insulation.

Q: What are the consequences of ignoring a damaged MAP sensor grommet?

A: Ignoring a damaged grommet can lead to a cascade of problems, including engine misfires, reduced power output, increased fuel consumption, and premature sensor failure, ultimately impacting the vehicle’s overall performance and longevity.

Tips for Maintaining a Healthy MAP Sensor Grommet:

- Regular Inspections: Inspect the grommet during routine maintenance checks for any signs of wear and tear.

- Proper Cleaning: Clean the grommet and surrounding area regularly to remove dirt, debris, and other contaminants.

- Avoid Harsh Chemicals: Avoid using harsh chemicals or cleaners that can damage the grommet material.

- Use Genuine Parts: When replacing a damaged grommet, always opt for a genuine OEM or a reputable aftermarket replacement.

Conclusion:

The MAP sensor grommet, though seemingly insignificant, plays a crucial role in protecting the MAP sensor from the harsh environment of the engine bay, ensuring its accurate operation and contributing to optimal engine performance. A healthy MAP sensor grommet is essential for maintaining smooth engine operation, fuel efficiency, and overall vehicle performance. By understanding the importance of this unsung hero and implementing preventative measures, you can ensure that your vehicle continues to run smoothly and efficiently for years to come.

Closure

Thus, we hope this article has provided valuable insights into The Unsung Hero of Engine Performance: The MAP Sensor Grommet. We appreciate your attention to our article. See you in our next article!