The Unsung Hero of Engine Performance: Understanding the MAP Sensor Gasket

Related Articles: The Unsung Hero of Engine Performance: Understanding the MAP Sensor Gasket

Introduction

In this auspicious occasion, we are delighted to delve into the intriguing topic related to The Unsung Hero of Engine Performance: Understanding the MAP Sensor Gasket. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

The Unsung Hero of Engine Performance: Understanding the MAP Sensor Gasket

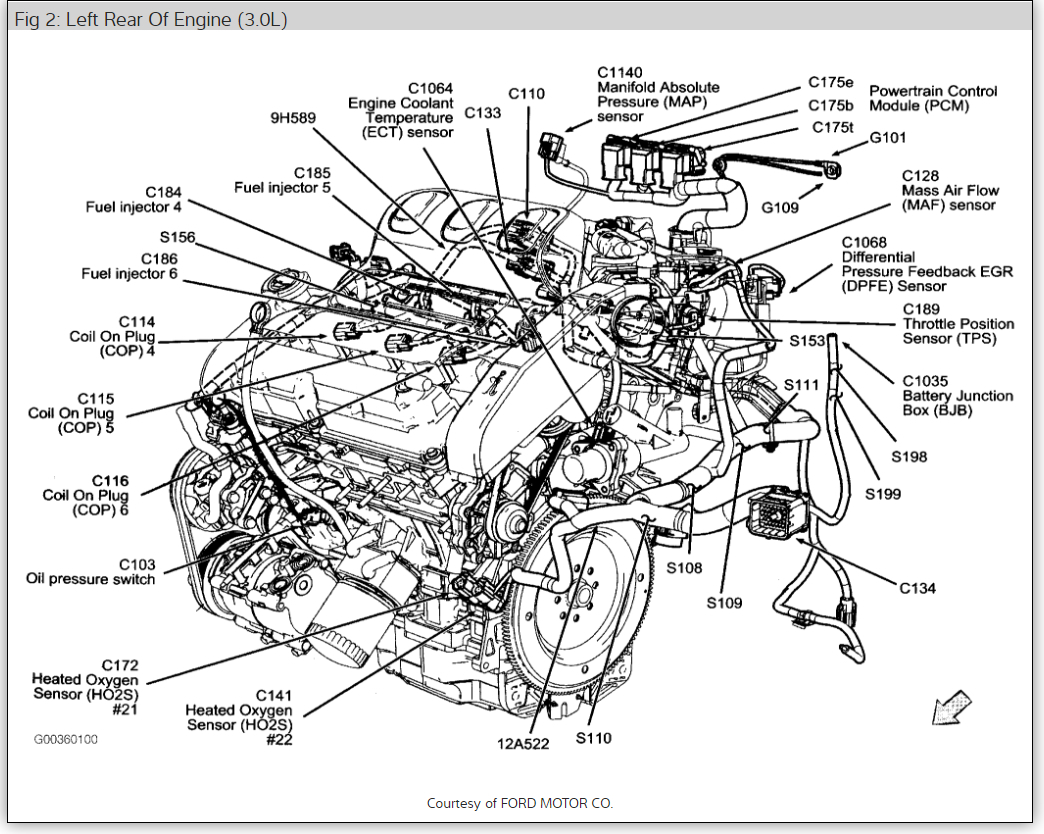

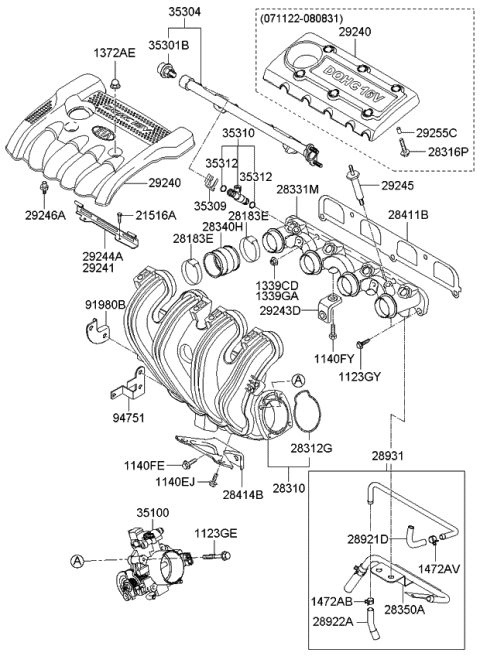

The intricate dance of air and fuel within an internal combustion engine is a delicate ballet, orchestrated by a symphony of sensors and actuators. Among these critical components, the manifold absolute pressure (MAP) sensor plays a crucial role in ensuring optimal engine operation. It measures the pressure within the intake manifold, providing the engine control unit (ECU) with vital information to calculate the appropriate air-fuel mixture. This information is then used to adjust the fuel injection timing and duration, ultimately impacting engine performance, fuel efficiency, and emissions.

However, the MAP sensor’s ability to accurately measure manifold pressure is highly dependent on the integrity of the gasket that seals it to the intake manifold. This seemingly small component, often overlooked in discussions of engine maintenance, plays a critical role in maintaining the engine’s health and performance.

The MAP Sensor Gasket: A Vital Component in a Complex System

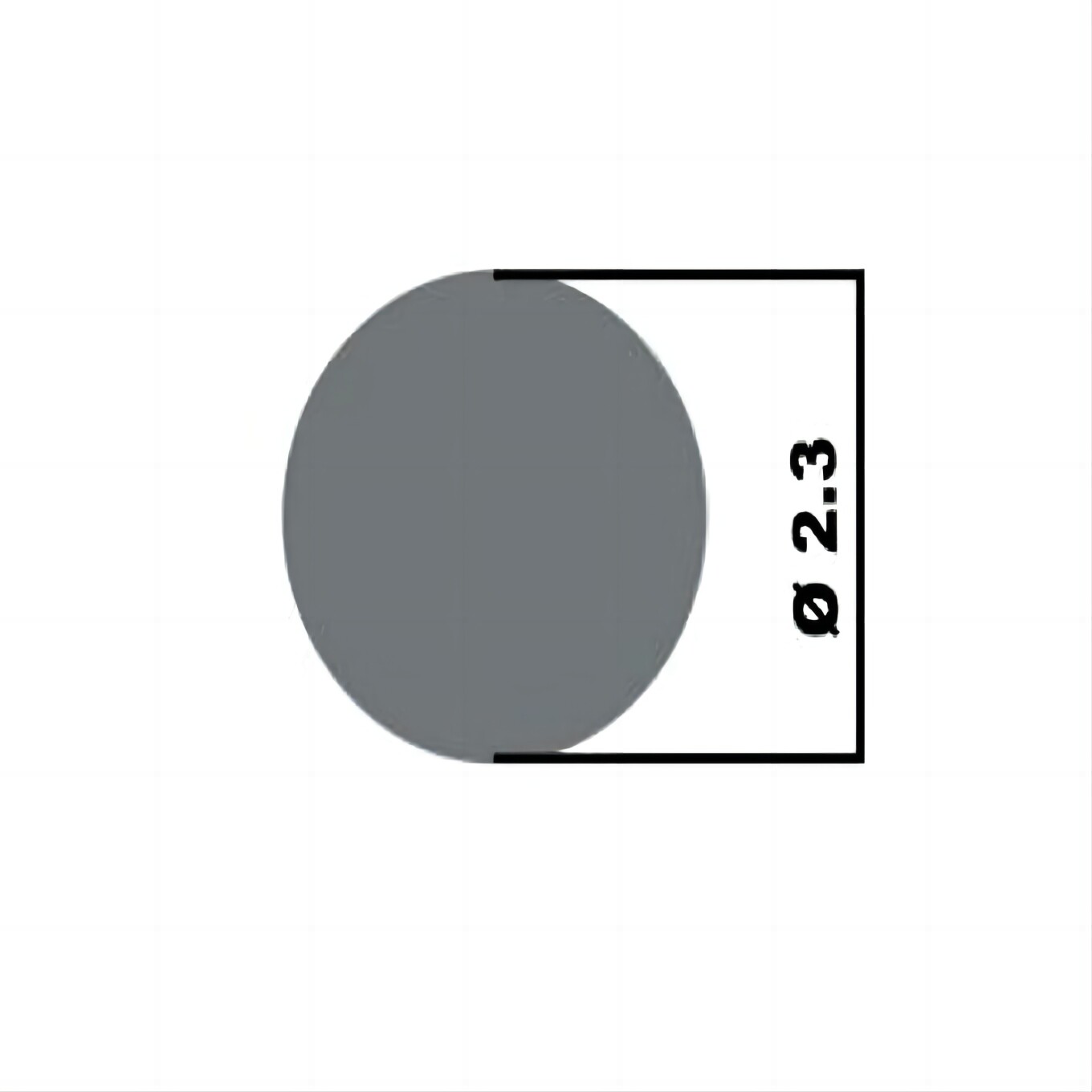

The MAP sensor gasket is a thin, often rubber or composite material, designed to create a tight seal between the sensor and the intake manifold. This seal is essential for several reasons:

- Accurate Pressure Measurement: A leaky gasket allows air to enter the manifold without passing through the sensor, leading to inaccurate pressure readings. This misinformation can cause the ECU to make incorrect fuel delivery adjustments, resulting in poor engine performance, rough idling, and increased fuel consumption.

- Preventing Contaminants: The gasket acts as a barrier against oil, dirt, and other contaminants that can damage the sensitive MAP sensor. A compromised gasket can allow these contaminants to enter the sensor, leading to inaccurate readings or even sensor failure.

- Maintaining Engine Efficiency: A leaking gasket can lead to a decrease in vacuum within the intake manifold, which can negatively impact the engine’s ability to draw in air. This reduction in airflow can result in reduced power output and increased emissions.

Signs of a Failing MAP Sensor Gasket:

While the MAP sensor gasket often remains hidden from view, its failure can manifest in several noticeable symptoms:

- Rough Idling: A faulty gasket can lead to inaccurate air-fuel mixture calculations, causing the engine to idle erratically or stall.

- Reduced Power: A leak in the gasket can reduce the amount of air entering the engine, resulting in a noticeable decrease in power output.

- Increased Fuel Consumption: The ECU’s inability to accurately determine the air-fuel ratio due to a faulty gasket can lead to increased fuel consumption.

- Check Engine Light: A faulty MAP sensor or its associated gasket will often trigger the check engine light, indicating a problem with the engine’s control system.

- Engine Backfire: In extreme cases, a leaking gasket can allow unburnt fuel to enter the exhaust system, leading to backfires.

Diagnosis and Replacement:

Diagnosing a faulty MAP sensor gasket often requires a combination of visual inspection and diagnostic testing. A visual inspection can reveal signs of leakage, such as oil or dirt around the sensor. A mechanic can use a pressure gauge to test the manifold pressure and compare it to the readings provided by the MAP sensor. If there is a significant discrepancy, it suggests a problem with the gasket.

Replacing a faulty MAP sensor gasket is a relatively straightforward procedure. It typically involves disconnecting the sensor from the wiring harness, removing the old gasket, cleaning the mating surfaces, and installing a new gasket. It is essential to ensure the gasket is properly seated and free of any debris before reconnecting the sensor and tightening the mounting bolts.

FAQs

Q: How often should I replace the MAP sensor gasket?

A: The MAP sensor gasket is typically a long-lasting component. However, it is recommended to inspect it during routine maintenance, such as oil changes or tune-ups, especially if the vehicle has experienced any of the symptoms mentioned above.

Q: Can I replace the MAP sensor gasket myself?

A: Replacing a MAP sensor gasket is a relatively simple procedure that can be done by a competent DIY enthusiast. However, if you are unfamiliar with automotive repair, it is best to consult a qualified mechanic.

Q: Is a faulty MAP sensor gasket a safety concern?

A: While a faulty MAP sensor gasket can lead to performance issues, it is not typically considered a safety concern unless it causes severe engine backfires or misfires.

Q: Can a faulty MAP sensor gasket affect emissions?

A: Yes, a faulty MAP sensor gasket can lead to increased emissions, as the engine may run rich or lean due to inaccurate air-fuel mixture calculations.

Tips for Maintaining the MAP Sensor Gasket:

- Regular Inspection: Inspect the MAP sensor gasket during routine maintenance to ensure it is in good condition and free of leaks.

- Cleanliness: Keep the area around the MAP sensor clean and free of debris to prevent contaminants from entering the sensor.

- Use Quality Parts: When replacing the MAP sensor gasket, ensure you are using a high-quality replacement part from a reputable manufacturer.

Conclusion

The MAP sensor gasket, though often overlooked, plays a critical role in ensuring the smooth and efficient operation of an internal combustion engine. Its role in maintaining accurate pressure readings, preventing contamination, and maximizing engine efficiency cannot be overstated. By understanding the importance of this seemingly small component, and addressing any issues promptly, vehicle owners can ensure their engines perform at their best, maximizing fuel economy, reducing emissions, and enjoying a smoother driving experience.

Closure

Thus, we hope this article has provided valuable insights into The Unsung Hero of Engine Performance: Understanding the MAP Sensor Gasket. We hope you find this article informative and beneficial. See you in our next article!