The Unsung Hero of Engine Performance: Understanding the MAP Sensor O-Ring

Related Articles: The Unsung Hero of Engine Performance: Understanding the MAP Sensor O-Ring

Introduction

In this auspicious occasion, we are delighted to delve into the intriguing topic related to The Unsung Hero of Engine Performance: Understanding the MAP Sensor O-Ring. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

The Unsung Hero of Engine Performance: Understanding the MAP Sensor O-Ring

The intricate dance of modern internal combustion engines relies on a symphony of sensors and actuators, each playing a vital role in maintaining optimal performance. While components like the engine control unit (ECU) and fuel injectors often take center stage, a seemingly insignificant element, the manifold absolute pressure (MAP) sensor o-ring, quietly safeguards the accuracy of crucial engine data. This small, yet indispensable component ensures the seamless flow of information between the engine’s intake manifold and the ECU, contributing significantly to fuel efficiency, power delivery, and overall engine health.

A Closer Look at the MAP Sensor O-Ring

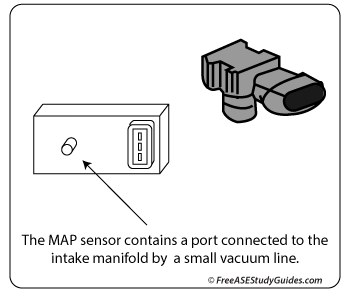

The MAP sensor o-ring is a circular seal, typically made of rubber or silicone, strategically placed between the MAP sensor and the intake manifold. Its primary function is to create a hermetic seal, preventing air leaks that could compromise the accuracy of the MAP sensor’s readings.

The MAP Sensor: A Vital Engine Component

The MAP sensor itself is a critical component responsible for measuring the absolute pressure within the intake manifold. This pressure, which fluctuates with engine load and speed, provides the ECU with vital information about the amount of air entering the engine. This data is then used to calculate the appropriate fuel injection timing and volume, ensuring optimal combustion and power delivery.

The Role of the MAP Sensor O-Ring in Engine Performance

The MAP sensor o-ring’s seemingly simple task of preventing air leaks is paramount to the accurate operation of the MAP sensor and, consequently, the entire engine system. A compromised o-ring can lead to a variety of issues, including:

- Inaccurate Engine Data: Air leaks disrupt the pressure readings within the intake manifold, resulting in inaccurate data being sent to the ECU. This can lead to erratic fuel delivery, causing issues like engine misfires, poor fuel economy, and reduced power.

- Engine Misfires: When the ECU receives incorrect pressure data, it may miscalculate fuel injection timing, leading to misfires. This can cause rough idling, engine hesitation, and even engine damage.

- Check Engine Light: A faulty o-ring often triggers a check engine light, prompting the need for diagnostics and repairs.

- Reduced Fuel Economy: Inaccurate fuel delivery due to air leaks results in inefficient fuel combustion, leading to a decrease in fuel economy.

- Increased Emissions: Incomplete combustion due to misfires can increase harmful emissions, contributing to environmental pollution.

Signs of a Faulty MAP Sensor O-Ring

While a faulty o-ring might not always be immediately apparent, several symptoms can indicate its deterioration:

- Check Engine Light: A flashing or illuminated check engine light is a common indicator of a malfunctioning MAP sensor or its associated components, including the o-ring.

- Rough Idling: A rough idle can be caused by inaccurate fuel delivery, which may be attributed to a leaking o-ring.

- Engine Hesitation: If the engine hesitates or stumbles during acceleration, it could be due to inconsistent fuel delivery stemming from a faulty o-ring.

- Reduced Power: A decrease in engine power can be a symptom of a faulty MAP sensor or a leaking o-ring affecting fuel delivery.

- Increased Fuel Consumption: Higher-than-usual fuel consumption can indicate inefficient combustion due to a faulty o-ring.

Replacing the MAP Sensor O-Ring: A Simple Fix

Replacing a worn-out MAP sensor o-ring is a relatively straightforward procedure that can be performed by a skilled mechanic. The process typically involves:

- Disconnecting the MAP Sensor: The MAP sensor is typically connected to the intake manifold with a single electrical connector and a vacuum hose. These need to be disconnected carefully.

- Removing the Old O-Ring: The old o-ring can be carefully removed from the MAP sensor using a small flat-head screwdriver or a similar tool.

- Installing the New O-Ring: The new o-ring should be lubricated with a small amount of silicone grease or engine oil to facilitate installation. It should be carefully placed in the groove on the MAP sensor, ensuring a proper seal.

- Reinstalling the MAP Sensor: The MAP sensor is then reinstalled onto the intake manifold, ensuring the vacuum hose and electrical connector are securely reconnected.

FAQs about MAP Sensor O-Rings

Q: How often should a MAP sensor o-ring be replaced?

A: While there’s no set schedule for replacing the o-ring, it’s recommended to inspect it during routine maintenance or if you suspect a problem with the MAP sensor. Signs of wear and tear, such as cracks, tears, or hardening, indicate the need for replacement.

Q: Can I use any type of o-ring for my MAP sensor?

A: It’s crucial to use the correct o-ring for your specific MAP sensor. Using an incompatible o-ring can lead to leaks, improper sealing, and potential damage to the sensor. Always consult your vehicle’s owner’s manual or a reputable parts supplier for the correct o-ring size and material.

Q: Can I replace the MAP sensor o-ring myself?

A: While replacing the o-ring is a relatively simple procedure, it requires some mechanical knowledge and tools. If you’re not comfortable working on your vehicle, it’s best to consult a qualified mechanic.

Tips for Maintaining Your MAP Sensor O-Ring

- Regular Inspections: Regularly inspect the MAP sensor o-ring for signs of wear and tear.

- Proper Lubrication: Apply a small amount of silicone grease or engine oil to the o-ring during installation to ensure a proper seal.

- Avoid Overtightening: Overtightening the MAP sensor can damage the o-ring and create leaks.

- Use Quality Parts: Always use genuine OEM parts or high-quality aftermarket replacements to ensure long-lasting performance.

Conclusion

The MAP sensor o-ring, often overlooked in the grand scheme of engine components, plays a crucial role in maintaining accurate engine data and ensuring optimal performance. Its ability to prevent air leaks safeguards the integrity of the MAP sensor’s readings, contributing to efficient fuel delivery, smooth engine operation, and reduced emissions. By understanding the importance of this seemingly insignificant component and taking preventative measures, you can contribute to the longevity and performance of your vehicle’s engine.

Closure

Thus, we hope this article has provided valuable insights into The Unsung Hero of Engine Performance: Understanding the MAP Sensor O-Ring. We hope you find this article informative and beneficial. See you in our next article!