The Unsung Heroes of Engine Control: MAP and MAF Sensors

Related Articles: The Unsung Heroes of Engine Control: MAP and MAF Sensors

Introduction

In this auspicious occasion, we are delighted to delve into the intriguing topic related to The Unsung Heroes of Engine Control: MAP and MAF Sensors. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

The Unsung Heroes of Engine Control: MAP and MAF Sensors

Modern internal combustion engines are marvels of engineering, capable of delivering power and efficiency with remarkable precision. This feat is achieved through sophisticated electronic control systems that constantly monitor and adjust engine parameters to optimize performance. Two key components in this intricate dance are the Manifold Absolute Pressure (MAP) sensor and the Mass Airflow (MAF) sensor. These sensors act as the engine’s "eyes and ears," providing vital information to the engine control unit (ECU) for precise fuel and ignition timing adjustments.

MAP Sensor: The Engine’s Barometer

The MAP sensor, as its name suggests, measures the absolute pressure within the engine’s intake manifold. This pressure reflects the amount of air drawn into the cylinders during each intake stroke. The sensor typically employs a piezoresistive element, a material whose resistance changes proportionally to applied pressure. This resistance change is converted into an electrical signal that the ECU interprets.

The MAP sensor plays a crucial role in determining the amount of fuel injected into the engine. The ECU uses the pressure reading to calculate the air density, which is essential for calculating the correct fuel-to-air ratio. A higher manifold pressure indicates denser air, requiring more fuel for optimal combustion. Conversely, a lower pressure suggests less dense air, requiring less fuel.

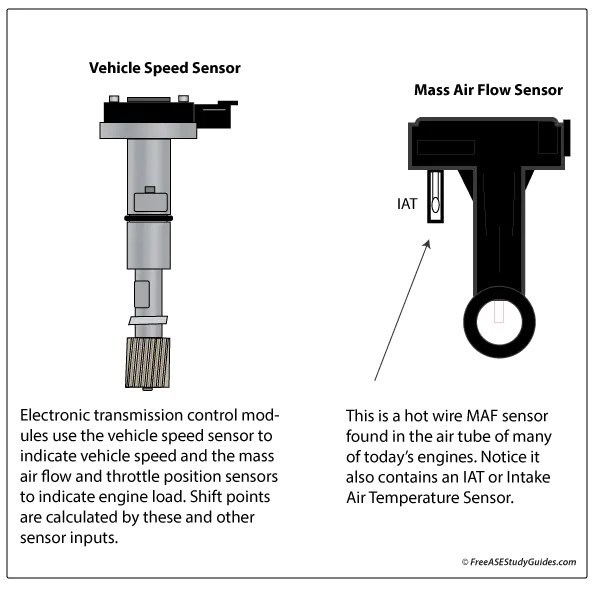

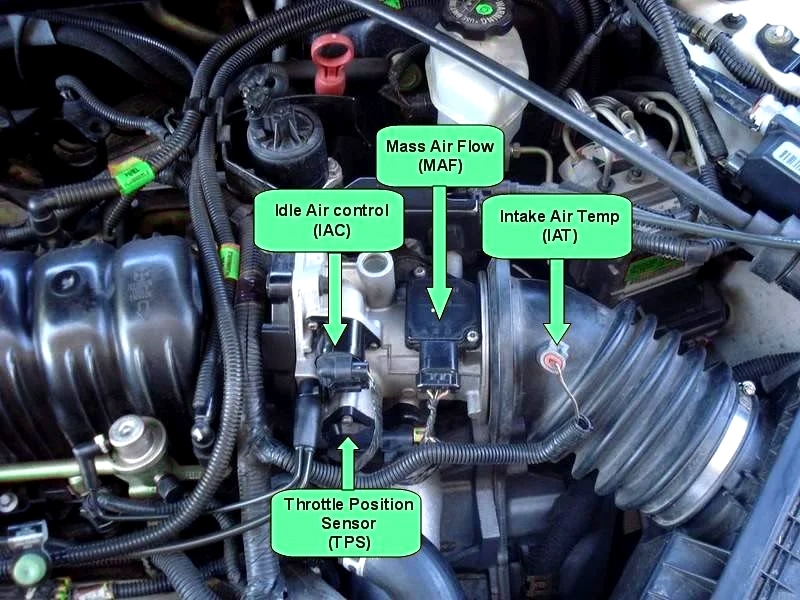

MAF Sensor: Weighing the Air Intake

The MAF sensor, on the other hand, measures the mass of air flowing into the engine. This is achieved by using a hot-wire sensor, a thin wire heated to a specific temperature. As air flows through the sensor, it cools the wire. The sensor measures the amount of electrical current required to maintain the wire’s temperature, which is directly proportional to the mass of air passing through.

The MAF sensor provides the ECU with a precise measurement of the actual amount of air entering the engine. This information is vital for accurate fuel injection and ignition timing adjustments. Unlike the MAP sensor, the MAF sensor provides a direct measurement of air mass, eliminating the need for the ECU to calculate air density.

The Importance of MAP and MAF Sensors

Both MAP and MAF sensors are indispensable for optimal engine performance and fuel efficiency. They work together to ensure the correct air-fuel mixture is delivered to the cylinders, maximizing combustion efficiency and minimizing emissions.

Benefits of MAP and MAF Sensors

- Improved Fuel Efficiency: By accurately measuring air intake, these sensors enable precise fuel injection, minimizing fuel waste and maximizing fuel economy.

- Reduced Emissions: The optimized air-fuel ratio ensures cleaner combustion, leading to lower emissions of harmful gases.

- Enhanced Engine Performance: The accurate fuel and ignition timing adjustments provided by these sensors translate to smoother engine operation, increased power, and improved acceleration.

- Improved Drivability: The sensors contribute to a more responsive and predictable driving experience, with smoother transitions between different engine loads.

Common Issues with MAP and MAF Sensors

While these sensors are robust and reliable, they can sometimes malfunction due to various factors:

- Contamination: Dirt, oil, or debris can accumulate on the sensor’s sensitive elements, affecting its readings.

- Electrical Problems: Faulty wiring, loose connections, or corroded contacts can disrupt the sensor’s signal transmission.

- Mechanical Damage: Physical damage to the sensor, such as a broken wire or a punctured diaphragm, can render it unusable.

Symptoms of a Faulty MAP or MAF Sensor

A malfunctioning MAP or MAF sensor can lead to noticeable changes in engine behavior:

- Poor Fuel Economy: The engine may consume more fuel than usual, indicating an inaccurate air-fuel mixture.

- Rough Idle: The engine may idle erratically or stall, particularly at low speeds.

- Hesitation or Stalling: The engine may hesitate or stall during acceleration, especially at higher RPMs.

- Check Engine Light: The ECU will likely illuminate the check engine light to alert the driver of a potential issue.

- Poor Acceleration: The engine may feel sluggish or lack power, indicating insufficient fuel delivery.

- Black Smoke from Exhaust: Excessive fuel entering the combustion chamber can lead to black smoke from the exhaust, indicating a rich air-fuel mixture.

FAQs about MAP and MAF Sensors

Q: What is the difference between a MAP sensor and a MAF sensor?

A: The MAP sensor measures the absolute pressure in the intake manifold, while the MAF sensor measures the mass of air flowing into the engine. The MAP sensor provides an indirect measurement of air mass, while the MAF sensor provides a direct measurement.

Q: Which sensor is more important?

A: Both sensors are equally crucial for optimal engine performance. The MAP sensor provides information about the air density, while the MAF sensor measures the actual air mass.

Q: Can I replace a MAP sensor with a MAF sensor, or vice versa?

A: No, MAP and MAF sensors are not interchangeable. They are designed to function differently and provide distinct information to the ECU.

Q: Can I clean a dirty MAP or MAF sensor?

A: It is possible to clean a dirty MAP or MAF sensor, but it requires careful handling and specialized cleaning solutions. It is best to consult a professional mechanic for this task.

Q: How often should I replace a MAP or MAF sensor?

A: The lifespan of a MAP or MAF sensor varies depending on driving conditions and maintenance practices. However, they are typically considered long-lasting components, often lasting for the entire lifespan of the vehicle.

Tips for Maintaining MAP and MAF Sensors

- Regularly inspect the sensors for signs of contamination or damage.

- Clean the sensors with a specialized cleaning solution if necessary.

- Avoid using harsh chemicals or abrasive materials that could damage the sensitive elements.

- Ensure proper wiring and connections to prevent electrical issues.

- Address any engine problems promptly to prevent further damage to the sensors.

Conclusion

The MAP and MAF sensors are essential components in the intricate dance of modern engine control systems. They act as the engine’s "eyes and ears," providing vital information to the ECU for precise fuel and ignition timing adjustments. By ensuring accurate air-fuel ratios, these sensors contribute to improved fuel efficiency, reduced emissions, enhanced engine performance, and a smoother driving experience. While these sensors are generally robust and reliable, regular maintenance and prompt attention to any warning signs can help ensure their continued optimal performance and the overall health of your engine.

Closure

Thus, we hope this article has provided valuable insights into The Unsung Heroes of Engine Control: MAP and MAF Sensors. We thank you for taking the time to read this article. See you in our next article!