The Vital Role of Manifold Absolute Pressure in Engine Performance

Related Articles: The Vital Role of Manifold Absolute Pressure in Engine Performance

Introduction

In this auspicious occasion, we are delighted to delve into the intriguing topic related to The Vital Role of Manifold Absolute Pressure in Engine Performance. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

The Vital Role of Manifold Absolute Pressure in Engine Performance

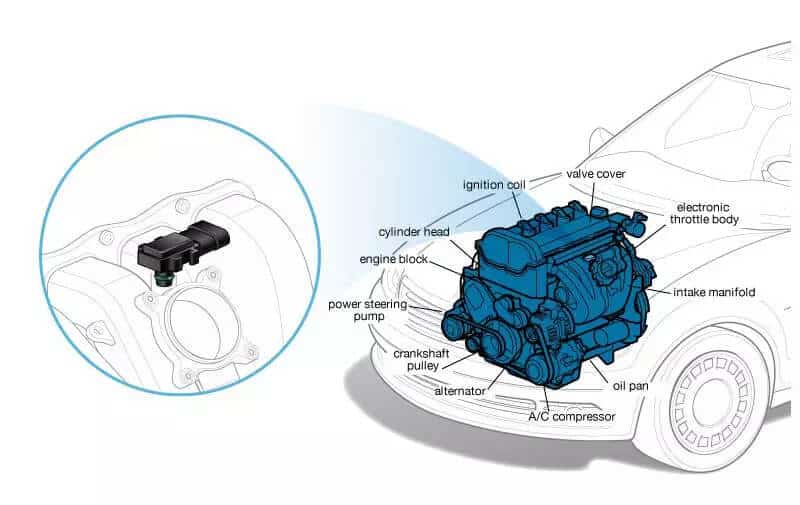

In the intricate world of internal combustion engines, manifold absolute pressure (MAP) plays a pivotal role in ensuring optimal performance and fuel efficiency. This seemingly simple measurement, representing the pressure within the engine’s intake manifold, serves as a crucial input for the engine control unit (ECU), influencing critical engine functions like fuel injection timing, ignition timing, and even exhaust gas recirculation (EGR) control.

Understanding MAP: A Pressure Gauge for Engine Efficiency

Imagine the intake manifold as the engine’s "lungs," where air is drawn in before being mixed with fuel and ignited. The MAP sensor, strategically positioned within the intake manifold, measures the absolute pressure of this air. This pressure is not just a static value; it fluctuates dynamically with engine speed, load, and throttle position. The ECU, using this real-time pressure data, adjusts various parameters to ensure efficient combustion and optimal engine output.

The Intricate Dance of MAP and Engine Control

Let’s delve deeper into how MAP influences engine control:

- Fuel Injection Timing: A higher MAP indicates a greater demand for fuel. The ECU responds by increasing the amount of fuel injected, ensuring a richer air-fuel mixture for efficient combustion under higher engine loads.

- Ignition Timing: The MAP sensor’s data allows the ECU to adjust ignition timing, ensuring optimal spark timing for different engine conditions. A higher MAP generally corresponds to an advanced ignition timing for better combustion efficiency.

- Exhaust Gas Recirculation (EGR) Control: The MAP sensor plays a crucial role in controlling the EGR system, which recycles exhaust gases back into the intake manifold. This process reduces nitrogen oxide emissions by diluting the air-fuel mixture. The ECU uses MAP data to determine the appropriate amount of EGR flow for optimal emissions control.

The Importance of Accurate MAP Readings

The accuracy of MAP sensor readings is paramount for optimal engine performance. A malfunctioning sensor can lead to a cascade of issues:

- Poor Fuel Economy: Inaccurate MAP readings can result in an incorrect air-fuel mixture, leading to fuel wastage and reduced efficiency.

- Engine Misfire: A faulty sensor can lead to incorrect ignition timing, causing misfires and rough engine operation.

- Increased Emissions: Incorrect EGR control due to a faulty MAP sensor can result in higher emissions levels, potentially exceeding regulatory limits.

- Check Engine Light (CEL): The ECU, recognizing a faulty sensor, will illuminate the CEL, signaling the need for a diagnostic check and potential repairs.

Troubleshooting a Faulty MAP Sensor

Diagnosing a faulty MAP sensor often involves a combination of visual inspection, diagnostic scans, and pressure testing. Here are some common signs of a failing MAP sensor:

- Engine Stalling: An inaccurate MAP reading might lead to insufficient fuel delivery, causing the engine to stall, particularly under heavy acceleration.

- Rough Idle: Fluctuating MAP readings can disrupt the engine’s idle speed, resulting in a rough idle.

- Hesitation During Acceleration: A faulty MAP sensor can cause hesitation or sluggish acceleration as the ECU receives inconsistent pressure data.

- Reduced Power: An inaccurate MAP reading can lead to an overly lean air-fuel mixture, resulting in reduced engine power.

Replacing a Faulty MAP Sensor

If a faulty MAP sensor is suspected, it’s crucial to replace it with a genuine part from a reputable manufacturer. Attempting to repair a faulty sensor is generally not recommended, as it often involves complex internal components.

Frequently Asked Questions about MAP Sensor Pressure

Q: How does a MAP sensor work?

A: A MAP sensor typically utilizes a diaphragm that flexes in response to pressure changes within the intake manifold. This flexing is measured by a strain gauge or a variable resistor, which converts the pressure into an electrical signal that the ECU can interpret.

Q: What are the common causes of a faulty MAP sensor?

A: Common causes include:

- Vacuum Leaks: Leaks in the intake manifold or vacuum lines can disrupt the pressure readings.

- Contamination: Dirt or debris can clog the sensor, affecting its performance.

- Electrical Failures: Problems with wiring or connectors can disrupt the sensor’s signal transmission.

- Sensor Degradation: Over time, the sensor’s internal components can wear out, leading to inaccurate readings.

Q: How can I test a MAP sensor?

A: Testing a MAP sensor typically involves:

- Visual Inspection: Check for any physical damage or signs of contamination.

- Diagnostic Scan: Use an OBD-II scanner to retrieve diagnostic trouble codes related to the MAP sensor.

- Pressure Testing: Use a vacuum pump and pressure gauge to check the sensor’s output against a known pressure.

Q: Can I replace a MAP sensor myself?

A: Replacing a MAP sensor is generally a straightforward procedure, but it requires basic mechanical knowledge and tools. Refer to your vehicle’s repair manual for specific instructions.

Tips for Maintaining MAP Sensor Performance

- Regular Maintenance: Ensure regular engine maintenance, including air filter replacement, to prevent contamination and ensure proper airflow.

- Vacuum Line Inspection: Periodically inspect vacuum lines for leaks and replace them if necessary.

- Avoid Contaminating the Sensor: When working on the engine, avoid introducing dirt or debris that could clog the sensor.

Conclusion: A Vital Component for Engine Health

The manifold absolute pressure sensor, despite its seemingly simple function, plays a crucial role in ensuring optimal engine performance and fuel efficiency. By providing the ECU with real-time pressure data, the MAP sensor enables precise control of fuel injection, ignition timing, and exhaust gas recirculation, resulting in a smoother, more efficient, and environmentally friendly engine operation. Regular maintenance and prompt replacement of a faulty sensor are essential for maintaining engine health and preventing costly repairs down the line.

Closure

Thus, we hope this article has provided valuable insights into The Vital Role of Manifold Absolute Pressure in Engine Performance. We thank you for taking the time to read this article. See you in our next article!