The Vital Role of the 3-Bar Manifold Absolute Pressure Sensor in Modern Engines

Related Articles: The Vital Role of the 3-Bar Manifold Absolute Pressure Sensor in Modern Engines

Introduction

With enthusiasm, let’s navigate through the intriguing topic related to The Vital Role of the 3-Bar Manifold Absolute Pressure Sensor in Modern Engines. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

The Vital Role of the 3-Bar Manifold Absolute Pressure Sensor in Modern Engines

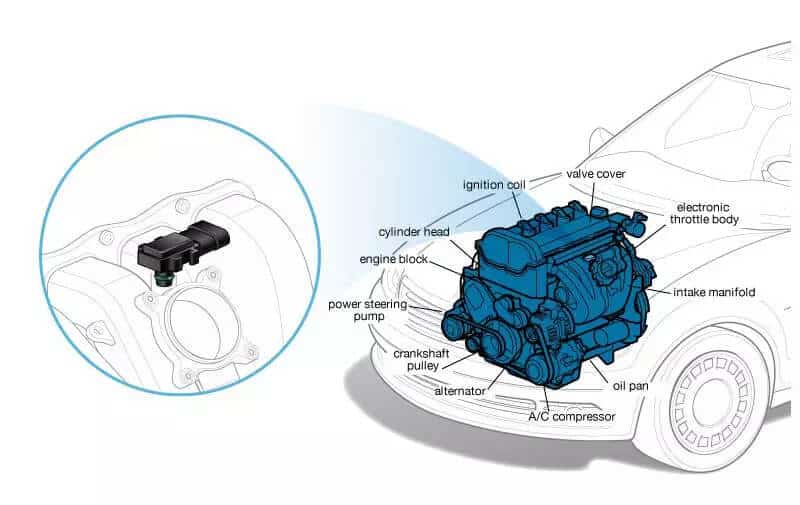

The modern internal combustion engine relies on a complex interplay of sensors and actuators to achieve optimal performance and efficiency. Among these crucial components, the manifold absolute pressure (MAP) sensor plays a pivotal role in accurately measuring engine load and informing the engine control unit (ECU) about the conditions within the intake manifold. While various MAP sensors exist, the 3-bar MAP sensor, with its ability to measure a wider range of pressures, has become increasingly prevalent in contemporary automotive applications.

Understanding the MAP Sensor’s Function

The MAP sensor, essentially a pressure transducer, converts the pressure inside the intake manifold into an electrical signal that the ECU can interpret. This pressure, known as manifold absolute pressure, is directly proportional to the amount of air entering the engine. By understanding this pressure, the ECU can accurately determine the engine load, a crucial parameter for optimizing fuel injection, ignition timing, and other critical engine functions.

The Significance of the 3-Bar MAP Sensor

The 3-bar MAP sensor, compared to its 1-bar counterpart, boasts a significantly expanded pressure measurement range. This allows it to accurately measure higher manifold pressures, which are often encountered in engines with forced induction, such as turbochargers or superchargers. These engines generate significantly higher boost pressures, exceeding the measurement capacity of traditional 1-bar MAP sensors.

The 3-bar sensor’s ability to handle higher pressures offers several advantages:

- Accurate Load Measurement: The wider pressure range ensures accurate load measurement, even under high boost conditions. This allows the ECU to precisely calculate the required fuel and ignition timing adjustments, optimizing performance and efficiency.

- Enhanced Performance: Accurate load measurement under high boost conditions translates to optimal engine performance. The ECU can precisely control fuel delivery and ignition timing, maximizing power output while minimizing emissions.

- Improved Fuel Efficiency: By accurately determining the engine load, the ECU can optimize fuel delivery, reducing fuel consumption and enhancing overall fuel efficiency.

- Reduced Emissions: Precise control over fuel and ignition timing under high boost conditions minimizes emissions by ensuring complete combustion and reducing unburnt fuel.

Applications of the 3-Bar MAP Sensor

The 3-bar MAP sensor finds widespread application in modern automotive engines, particularly those equipped with forced induction. These include:

- Turbocharged Engines: Turbochargers generate significant boost pressures, requiring a sensor capable of measuring these high pressures for optimal engine control.

- Supercharged Engines: Superchargers, while generating lower boost pressures compared to turbochargers, still necessitate a 3-bar MAP sensor for accurate load measurement.

- High-Performance Engines: Performance-oriented engines often feature forced induction or high-revving characteristics, necessitating a 3-bar MAP sensor for precise engine control.

Common FAQs Regarding the 3-Bar MAP Sensor

Q: How does a 3-bar MAP sensor differ from a 1-bar MAP sensor?

A: The primary difference lies in their pressure measurement range. A 3-bar MAP sensor can measure pressures up to 3 bar (approximately 43.5 psi), while a 1-bar MAP sensor is limited to 1 bar (approximately 14.5 psi).

Q: When is a 3-bar MAP sensor necessary?

A: A 3-bar MAP sensor is necessary in applications where high boost pressures are encountered, such as turbocharged or supercharged engines.

Q: Can a 1-bar MAP sensor be used in a turbocharged engine?

A: Using a 1-bar MAP sensor in a turbocharged engine can lead to inaccurate load measurement and potential engine damage due to the sensor’s inability to accurately measure high boost pressures.

Q: What happens if a 3-bar MAP sensor fails?

A: A faulty 3-bar MAP sensor can lead to various issues, including:

- Reduced engine performance: Inaccurate load measurement can result in poor fuel delivery and ignition timing, reducing engine power and responsiveness.

- Increased fuel consumption: The ECU may overcompensate for inaccurate load readings, leading to excessive fuel consumption.

- Emissions problems: Incomplete combustion due to incorrect fuel and ignition timing can result in increased emissions.

- Check engine light: A faulty sensor will trigger a check engine light, indicating a problem that needs attention.

Tips for Maintaining the 3-Bar MAP Sensor

- Regular Inspection: Inspect the sensor for any signs of damage, leaks, or contamination.

- Cleanliness: Keep the sensor clean and free from debris.

- Avoid Excessive Boost: Avoid exceeding the sensor’s pressure range to prevent damage.

- Professional Diagnosis: If you suspect a problem with the sensor, seek professional diagnosis and repair.

Conclusion

The 3-bar MAP sensor plays a crucial role in modern engines, particularly those with forced induction. Its ability to accurately measure higher pressures ensures precise engine control, optimizing performance, efficiency, and emissions. Recognizing its significance and understanding its function is essential for maintaining optimal engine health and performance. Regular inspection, proper maintenance, and prompt attention to any potential issues will ensure the long-term reliability and efficiency of this vital engine component.

Closure

Thus, we hope this article has provided valuable insights into The Vital Role of the 3-Bar Manifold Absolute Pressure Sensor in Modern Engines. We hope you find this article informative and beneficial. See you in our next article!