The Vital Role of the GM 1 Bar MAP Sensor in Modern Automotive Systems

Related Articles: The Vital Role of the GM 1 Bar MAP Sensor in Modern Automotive Systems

Introduction

In this auspicious occasion, we are delighted to delve into the intriguing topic related to The Vital Role of the GM 1 Bar MAP Sensor in Modern Automotive Systems. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

The Vital Role of the GM 1 Bar MAP Sensor in Modern Automotive Systems

The automotive world is a complex interplay of intricate systems, each contributing to the smooth and efficient operation of a vehicle. Among these systems, the manifold absolute pressure (MAP) sensor stands out as a crucial component responsible for monitoring and regulating engine performance. Within this category, the GM 1 Bar MAP sensor plays a vital role in ensuring optimal engine operation, particularly in vehicles equipped with General Motors (GM) powertrains.

This article delves into the intricacies of the GM 1 Bar MAP sensor, its operational principles, and its significant contribution to modern automotive technology.

Understanding the MAP Sensor: A Gateway to Engine Performance

The MAP sensor, a critical component of the engine management system, serves as a vital link between the engine’s intake manifold and the Electronic Control Unit (ECU). Its primary function is to measure the absolute pressure within the intake manifold, providing the ECU with crucial data about the engine’s load and operating conditions. This information is then used to precisely control fuel injection, ignition timing, and other critical engine parameters, ensuring optimal performance and fuel efficiency.

Delving into the GM 1 Bar MAP Sensor: A Closer Look

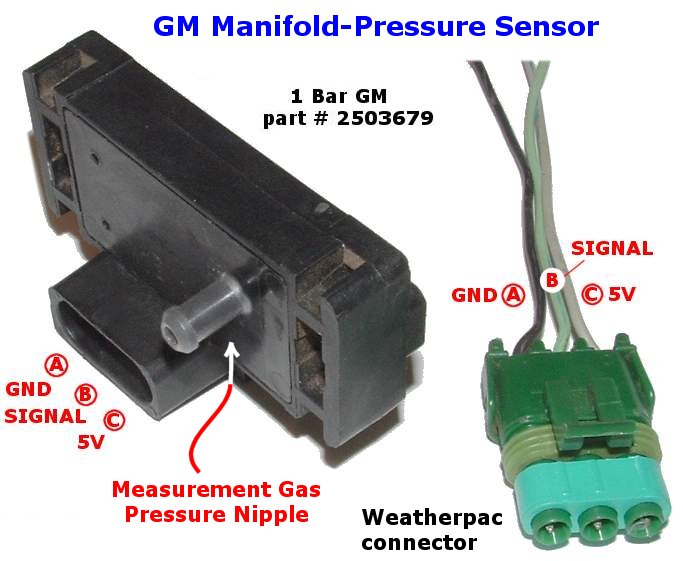

The GM 1 Bar MAP sensor, specifically designed for GM vehicles, is a piezoresistive pressure sensor capable of measuring pressure up to 1 bar (14.5 psi). This pressure range encompasses typical operating conditions for naturally aspirated gasoline engines, making it a suitable choice for a wide range of GM vehicles.

The Mechanics of the GM 1 Bar MAP Sensor: A Detailed Explanation

At its core, the GM 1 Bar MAP sensor comprises a diaphragm, a piezoresistive element, and a signal conditioning circuit. The diaphragm, a thin, flexible membrane, is exposed to the intake manifold pressure. As pressure changes within the intake manifold, the diaphragm deflects, altering the resistance of the piezoresistive element. This change in resistance is then converted into a voltage signal by the signal conditioning circuit, which is transmitted to the ECU.

Decoding the Signal: How the ECU Interprets MAP Sensor Data

The ECU receives the voltage signal from the MAP sensor and uses it to determine the absolute pressure within the intake manifold. This information is then used to calculate the engine load, which is a measure of the amount of air being drawn into the engine. The ECU uses this data to precisely control fuel injection, ignition timing, and other critical engine parameters, ensuring optimal performance and fuel efficiency.

The Importance of the GM 1 Bar MAP Sensor: Unveiling its Critical Role

The GM 1 Bar MAP sensor plays a crucial role in optimizing engine performance and fuel economy. Its contribution is multifaceted:

-

Accurate Fuel Injection: By providing the ECU with precise information about engine load, the MAP sensor enables the ECU to adjust fuel injection accordingly. This ensures that the engine receives the optimal amount of fuel for any given operating condition, minimizing fuel consumption and maximizing efficiency.

-

Optimal Ignition Timing: The MAP sensor also plays a vital role in determining the optimal ignition timing. By accurately measuring engine load, the ECU can adjust ignition timing to ensure efficient combustion and minimize emissions.

-

Smooth Engine Operation: The MAP sensor enables the ECU to adjust engine parameters in real-time, ensuring smooth and responsive engine operation across a wide range of driving conditions.

-

Enhanced Emissions Control: By optimizing fuel injection and ignition timing, the MAP sensor contributes to reducing harmful emissions, promoting cleaner and more environmentally friendly driving.

Common Issues and Troubleshooting: Addressing Potential Problems

While the GM 1 Bar MAP sensor is a reliable component, it can be susceptible to wear and tear over time. Common issues include:

-

Sensor Failure: The sensor itself may fail due to damage, contamination, or wear. This can result in inaccurate pressure readings, leading to engine performance problems, such as poor acceleration, rough idling, or stalling.

-

Vacuum Leaks: Leaks in the intake manifold or vacuum lines can affect the pressure readings of the MAP sensor, leading to inaccurate data and engine performance issues.

-

Electrical Problems: Faulty wiring or connectors can interrupt the signal transmission from the MAP sensor to the ECU, leading to engine malfunctions.

Troubleshooting Tips: Identifying and Resolving MAP Sensor Issues

When encountering engine performance problems, it is crucial to diagnose the issue accurately. Here are some helpful tips:

-

Visual Inspection: Inspect the MAP sensor for signs of damage, contamination, or loose connections.

-

Pressure Testing: Use a vacuum gauge to check for leaks in the intake manifold or vacuum lines.

-

Diagnostic Scanner: Utilize a diagnostic scanner to retrieve fault codes related to the MAP sensor.

-

Resistance Testing: Measure the resistance of the MAP sensor using a multimeter to determine if it is within the specified range.

-

Voltage Monitoring: Monitor the voltage signal output from the MAP sensor using a multimeter to assess its functionality.

FAQs: Addressing Common Questions about the GM 1 Bar MAP Sensor

Q: What are the symptoms of a faulty GM 1 Bar MAP sensor?

A: A faulty MAP sensor can manifest in various symptoms, including poor acceleration, rough idling, stalling, increased fuel consumption, and check engine light illumination.

Q: How often should I replace the GM 1 Bar MAP sensor?

A: The lifespan of a MAP sensor can vary depending on factors such as driving conditions and maintenance. However, it is generally recommended to replace the sensor every 100,000 miles or as needed based on its condition.

Q: Can I replace the GM 1 Bar MAP sensor myself?

A: Replacing the MAP sensor is a relatively straightforward procedure that can be performed by a competent DIY mechanic. However, it is essential to follow the manufacturer’s instructions and use appropriate tools to ensure proper installation.

Q: What is the cost of a new GM 1 Bar MAP sensor?

A: The cost of a new GM 1 Bar MAP sensor can vary depending on the vehicle model and the source of purchase. However, it typically ranges from $20 to $100.

Conclusion: The Unwavering Importance of the GM 1 Bar MAP Sensor

The GM 1 Bar MAP sensor is an indispensable component in modern automotive systems, playing a crucial role in optimizing engine performance, fuel efficiency, and emissions control. Understanding its function, common issues, and troubleshooting techniques is essential for maintaining optimal vehicle performance and ensuring a safe and enjoyable driving experience. By recognizing the critical role of the MAP sensor and addressing any potential problems promptly, drivers can contribute to the longevity and reliability of their vehicles.

Closure

Thus, we hope this article has provided valuable insights into The Vital Role of the GM 1 Bar MAP Sensor in Modern Automotive Systems. We hope you find this article informative and beneficial. See you in our next article!