The Vital Role of the Manifold Absolute Pressure Sensor in Modern Engines

Related Articles: The Vital Role of the Manifold Absolute Pressure Sensor in Modern Engines

Introduction

In this auspicious occasion, we are delighted to delve into the intriguing topic related to The Vital Role of the Manifold Absolute Pressure Sensor in Modern Engines. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

The Vital Role of the Manifold Absolute Pressure Sensor in Modern Engines

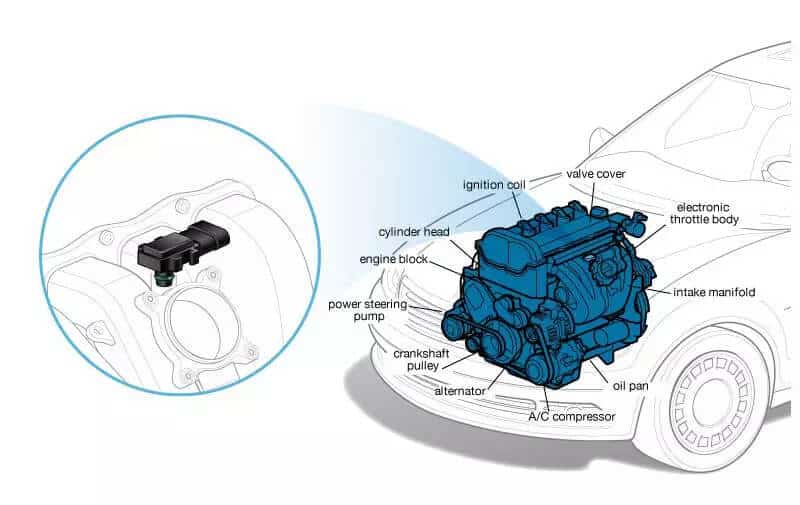

The intricate dance of combustion within an internal combustion engine relies on a delicate balance of air and fuel. This balance is meticulously controlled by a complex network of sensors and actuators, with one critical component being the Manifold Absolute Pressure (MAP) sensor. This sensor, often referred to by its specific designation, "N204," plays a pivotal role in ensuring optimal engine performance, fuel efficiency, and emission control.

Understanding the MAP Sensor’s Function:

The MAP sensor, essentially a pressure transducer, monitors the pressure within the engine’s intake manifold. This pressure, a direct indicator of the amount of air entering the cylinders, is crucial for determining the appropriate fuel-air mixture for combustion.

How it Works:

The MAP sensor typically operates on a piezoresistive principle. A thin diaphragm within the sensor is exposed to the manifold pressure. As the pressure changes, the diaphragm flexes, altering the resistance of a tiny electrical circuit. This resistance change is then translated into a voltage signal by the sensor’s electronics. This voltage signal, proportional to the manifold pressure, is transmitted to the engine control unit (ECU).

The MAP Sensor’s Influence on Engine Operation:

The information provided by the MAP sensor is instrumental in the ECU’s decision-making process. The ECU uses this data to:

- Calculate the appropriate fuel injection duration: By knowing the manifold pressure, the ECU can determine the amount of air entering the cylinders and calculate the precise amount of fuel needed for efficient combustion.

- Adjust ignition timing: The ECU adjusts the spark timing based on the manifold pressure, optimizing combustion efficiency and reducing emissions.

- Control other engine functions: The MAP sensor’s data is used to regulate various other engine systems, such as the throttle position sensor, idle speed control, and emissions control systems.

The Importance of a Functional MAP Sensor:

A faulty MAP sensor can have significant consequences for engine performance and overall vehicle operation. Some of the common symptoms associated with a malfunctioning MAP sensor include:

- Engine stalling or rough idling: An inaccurate reading from the MAP sensor can lead to an imbalanced fuel-air mixture, resulting in stalling or rough idling.

- Reduced engine power: A faulty sensor might cause the ECU to deliver an incorrect fuel-air ratio, resulting in reduced engine power and sluggish acceleration.

- Increased fuel consumption: An imbalanced fuel-air mixture can lead to inefficient combustion, resulting in increased fuel consumption.

- Emission problems: A malfunctioning MAP sensor can disrupt the engine’s ability to control emissions, leading to higher levels of pollutants.

- Check engine light illumination: A faulty MAP sensor will often trigger the check engine light, indicating a need for diagnosis and repair.

Diagnosing MAP Sensor Issues:

Diagnosing a faulty MAP sensor typically involves a combination of visual inspection, diagnostic testing, and data analysis. A mechanic can:

- Visually inspect the sensor: Check for any signs of damage, corrosion, or loose connections.

- Use a diagnostic scanner: The scanner can read sensor data and identify any discrepancies or error codes related to the MAP sensor.

- Perform a vacuum test: This test checks the sensor’s ability to respond to changes in manifold pressure.

- Compare sensor readings to known good values: Using a digital multimeter, the mechanic can compare the sensor’s output voltage to known good values for the specific engine model.

Tips for Maintaining the MAP Sensor:

While MAP sensors are generally robust and reliable, there are steps you can take to ensure their longevity:

- Regularly inspect the sensor for damage or corrosion: Ensure the sensor is clean and free from debris.

- Avoid excessive engine modifications: Modifying the engine intake system or exhaust system can disrupt the sensor’s operation.

- Use quality fuel and engine fluids: Using low-quality fuel or fluids can lead to deposits that may clog the sensor or its associated lines.

Frequently Asked Questions (FAQs) about the MAP Sensor:

Q: How often should I replace the MAP sensor?

A: MAP sensors are generally quite durable and can last for many years. However, they are subject to wear and tear, and eventually, they will need to be replaced. The average lifespan of a MAP sensor is around 100,000 miles. If you notice any of the symptoms mentioned above, it’s a good idea to have the sensor inspected.

Q: Can I replace the MAP sensor myself?

A: Replacing the MAP sensor can be a relatively simple procedure, depending on the vehicle model. However, if you are not comfortable working on your vehicle’s engine, it’s best to have a qualified mechanic perform the replacement.

Q: What are the risks of driving with a faulty MAP sensor?

A: Driving with a faulty MAP sensor can lead to a number of problems, including reduced engine performance, increased fuel consumption, and emission issues. In some cases, a faulty MAP sensor can even cause the engine to stall or fail to start.

Q: Can I clean the MAP sensor?

A: While some people recommend cleaning the MAP sensor, it’s generally not advisable. Cleaning the sensor can damage its delicate internal components. If you suspect the sensor is dirty, it’s best to replace it with a new one.

Conclusion:

The MAP sensor, often designated as N204, is an essential component in modern engine management systems. Its ability to accurately measure manifold pressure provides vital information for the ECU, enabling precise control over fuel injection, ignition timing, and other critical engine functions. Understanding the importance and function of the MAP sensor allows drivers to recognize potential issues and ensure optimal engine performance, fuel efficiency, and emissions control.

Closure

Thus, we hope this article has provided valuable insights into The Vital Role of the Manifold Absolute Pressure Sensor in Modern Engines. We appreciate your attention to our article. See you in our next article!