The Vital Role of the TMAP Sensor in Cummins Engines: A Comprehensive Exploration

Related Articles: The Vital Role of the TMAP Sensor in Cummins Engines: A Comprehensive Exploration

Introduction

In this auspicious occasion, we are delighted to delve into the intriguing topic related to The Vital Role of the TMAP Sensor in Cummins Engines: A Comprehensive Exploration. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

The Vital Role of the TMAP Sensor in Cummins Engines: A Comprehensive Exploration

The modern diesel engine is a complex marvel of engineering, relying on intricate systems to deliver efficient and reliable power. Among these systems, the manifold absolute pressure (MAP) sensor plays a crucial role in ensuring optimal engine performance. This article delves into the workings of the MAP sensor in Cummins engines, highlighting its importance and the benefits it provides.

Understanding the TMAP Sensor and Its Function

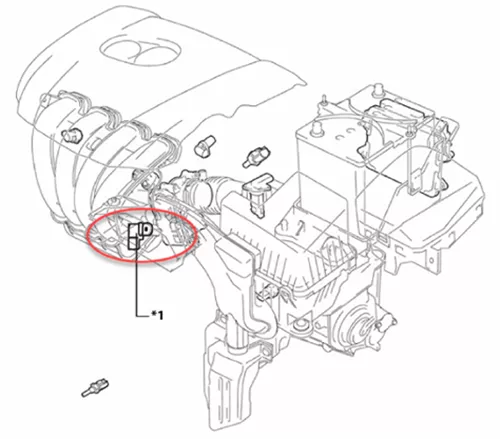

The TMAP sensor, or turbocharged manifold absolute pressure sensor, is an integral component in Cummins engines equipped with turbochargers. It is a crucial element in the engine control unit (ECU)’s ability to regulate air intake and fuel injection, ultimately impacting engine power, fuel efficiency, and emissions.

How the TMAP Sensor Works

The TMAP sensor operates on the principle of pressure transduction. It measures the absolute pressure within the intake manifold, a critical parameter in determining the amount of air entering the engine cylinders.

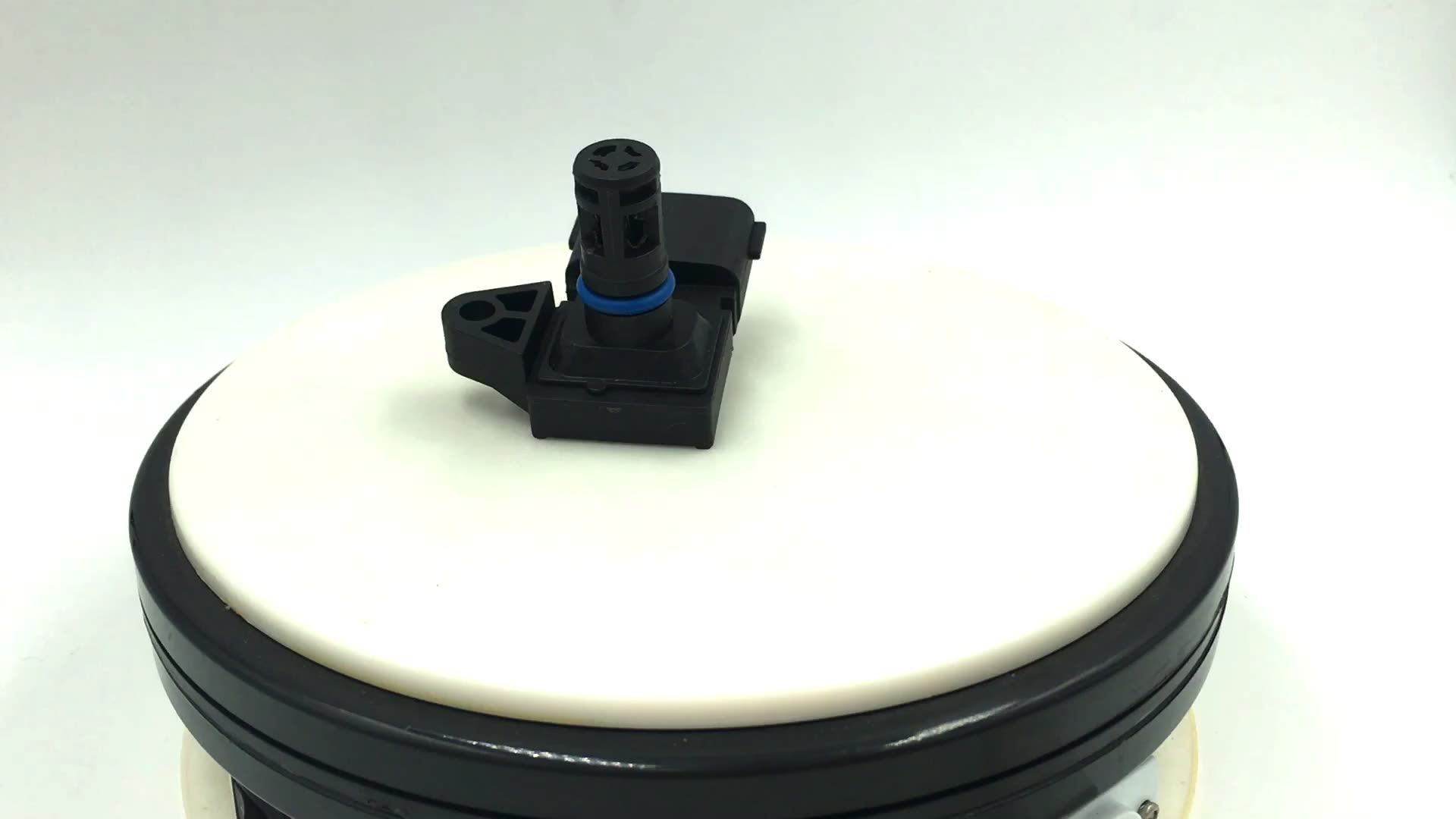

- Physical Structure: The sensor consists of a diaphragm, a pressure transducer, and an electrical circuit. The diaphragm, exposed to the intake manifold pressure, deflects proportionally to the pressure fluctuations.

- Pressure Transduction: The diaphragm’s movement is detected by the pressure transducer, which converts the mechanical pressure change into an electrical signal. This signal is then transmitted to the ECU.

- ECU Interpretation: The ECU interprets the electrical signal from the TMAP sensor, translating it into a pressure reading. This information is used to calculate the air mass entering the engine, a key factor in determining the optimal fuel injection amount.

The Importance of the TMAP Sensor in Engine Performance

The TMAP sensor’s contribution to engine performance is multifaceted:

- Fuel Efficiency: Accurate measurement of intake manifold pressure allows the ECU to precisely adjust fuel injection timing and quantity, optimizing fuel consumption and reducing emissions.

- Power Output: By ensuring the correct air-to-fuel ratio, the TMAP sensor contributes to efficient combustion, maximizing engine power output.

- Emissions Control: The TMAP sensor plays a vital role in reducing harmful emissions by facilitating precise fuel injection, minimizing incomplete combustion.

- Engine Protection: The sensor helps prevent engine damage by detecting and responding to situations like excessive boost pressure or manifold leaks.

Signs of a Faulty TMAP Sensor

A malfunctioning TMAP sensor can significantly impact engine performance and potentially lead to serious problems. Recognizing the symptoms is crucial for timely diagnosis and repair:

- Engine Stalling or Hesitation: Inaccurate pressure readings can cause misfires, leading to stalling or hesitation during acceleration.

- Reduced Power Output: A faulty TMAP sensor can result in insufficient fuel injection, leading to a noticeable decrease in engine power.

- Increased Fuel Consumption: Miscalculated fuel injection can lead to increased fuel consumption, impacting overall efficiency.

- Check Engine Light: A malfunctioning TMAP sensor will typically trigger the check engine light, indicating a need for diagnosis and repair.

Troubleshooting and Replacing the TMAP Sensor

If a faulty TMAP sensor is suspected, a qualified mechanic should diagnose and address the issue.

- Diagnosis: The mechanic will use a diagnostic scanner to read the ECU’s fault codes, identifying any errors related to the TMAP sensor.

- Visual Inspection: The sensor itself should be inspected for signs of damage or corrosion.

- Pressure Testing: A pressure test can be conducted to verify the sensor’s accuracy and ensure it’s providing correct readings.

- Replacement: If the sensor is faulty, it should be replaced with a genuine Cummins part to ensure optimal performance and longevity.

FAQs Regarding the TMAP Sensor

Q: What is the lifespan of a TMAP sensor?

A: The lifespan of a TMAP sensor can vary depending on factors like operating conditions, maintenance practices, and environmental factors. Generally, they can last several years with proper care. However, they are susceptible to wear and tear, and eventually, they may require replacement.

Q: Can I clean a TMAP sensor?

A: Cleaning a TMAP sensor is not recommended. Attempting to clean the sensor can damage the delicate components and compromise its functionality. It’s best to replace a faulty sensor with a new one.

Q: Can I replace the TMAP sensor myself?

A: Replacing a TMAP sensor can be a complex procedure, requiring specialized tools and technical expertise. It’s advisable to consult a qualified mechanic for this task.

Q: What are the potential consequences of ignoring a faulty TMAP sensor?

A: Ignoring a faulty TMAP sensor can lead to various issues, including:

- Reduced engine performance and fuel efficiency.

- Increased emissions.

- Engine damage due to incorrect fuel injection.

- Premature engine wear and tear.

Tips for Maintaining the TMAP Sensor

- Regular Engine Maintenance: Adhering to scheduled engine maintenance, including oil changes and filter replacements, helps prevent contamination and prolong the lifespan of the TMAP sensor.

- Avoid Excessive Boost Pressure: Sustained high boost pressure can put stress on the sensor and shorten its lifespan. It’s crucial to operate the engine within recommended parameters.

- Protect from Environmental Factors: Exposure to excessive heat, moisture, and contaminants can damage the sensor. Protecting it from these elements can extend its lifespan.

Conclusion

The TMAP sensor is a critical component in Cummins engines, ensuring optimal performance, fuel efficiency, and emission control. Understanding its function, recognizing signs of failure, and practicing proper maintenance are essential for maximizing engine performance and longevity. By addressing any issues promptly, owners can ensure their Cummins engines continue to deliver reliable power and efficiency for years to come.

Closure

Thus, we hope this article has provided valuable insights into The Vital Role of the TMAP Sensor in Cummins Engines: A Comprehensive Exploration. We thank you for taking the time to read this article. See you in our next article!