Understanding the Bosch MAP Sensor: A Comprehensive Guide

Related Articles: Understanding the Bosch MAP Sensor: A Comprehensive Guide

Introduction

With great pleasure, we will explore the intriguing topic related to Understanding the Bosch MAP Sensor: A Comprehensive Guide. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

- 1 Related Articles: Understanding the Bosch MAP Sensor: A Comprehensive Guide

- 2 Introduction

- 3 Understanding the Bosch MAP Sensor: A Comprehensive Guide

- 3.1 The Role of MAP Sensors in Engine Management

- 3.2 The Bosch 0 261 230 099: A Detailed Look

- 3.3 Importance of a Functional MAP Sensor

- 3.4 Troubleshooting and Replacement

- 3.5 FAQs Regarding Bosch 0 261 230 099 MAP Sensor

- 3.6 Tips for Maintaining a MAP Sensor

- 3.7 Conclusion

- 4 Closure

Understanding the Bosch MAP Sensor: A Comprehensive Guide

The Bosch MAP sensor, with the part number 0 261 230 099, is a crucial component in modern automotive engines. This sensor plays a vital role in ensuring optimal engine performance by providing the engine control unit (ECU) with real-time information about the manifold absolute pressure (MAP). This information allows the ECU to make precise adjustments to fuel and ignition timing, ultimately leading to smoother engine operation, improved fuel efficiency, and reduced emissions.

The Role of MAP Sensors in Engine Management

Before delving into the specifics of the Bosch 0 261 230 099 sensor, it’s essential to understand the broader context of MAP sensors in engine management.

Engine control systems rely on various sensors to gather information about engine operating conditions. These sensors act as the "eyes and ears" of the ECU, providing critical data that enables the ECU to make informed decisions regarding fuel injection, ignition timing, and other parameters.

The MAP sensor is responsible for measuring the absolute pressure within the engine intake manifold. This pressure is directly related to the amount of air entering the engine during each intake stroke. By measuring this pressure, the ECU can determine the air mass entering the engine, which is a crucial factor in calculating the appropriate fuel-to-air ratio for combustion.

The Bosch 0 261 230 099: A Detailed Look

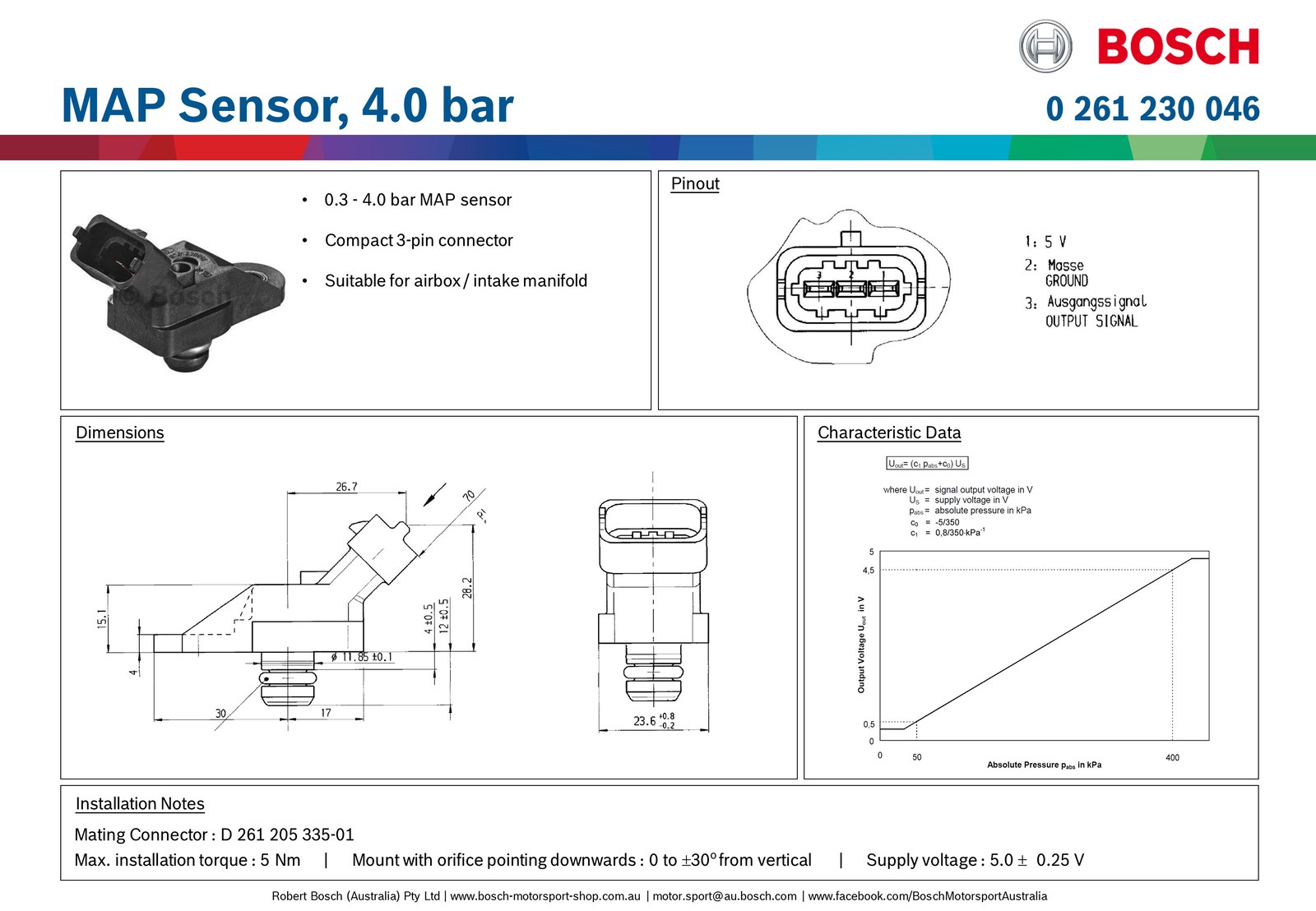

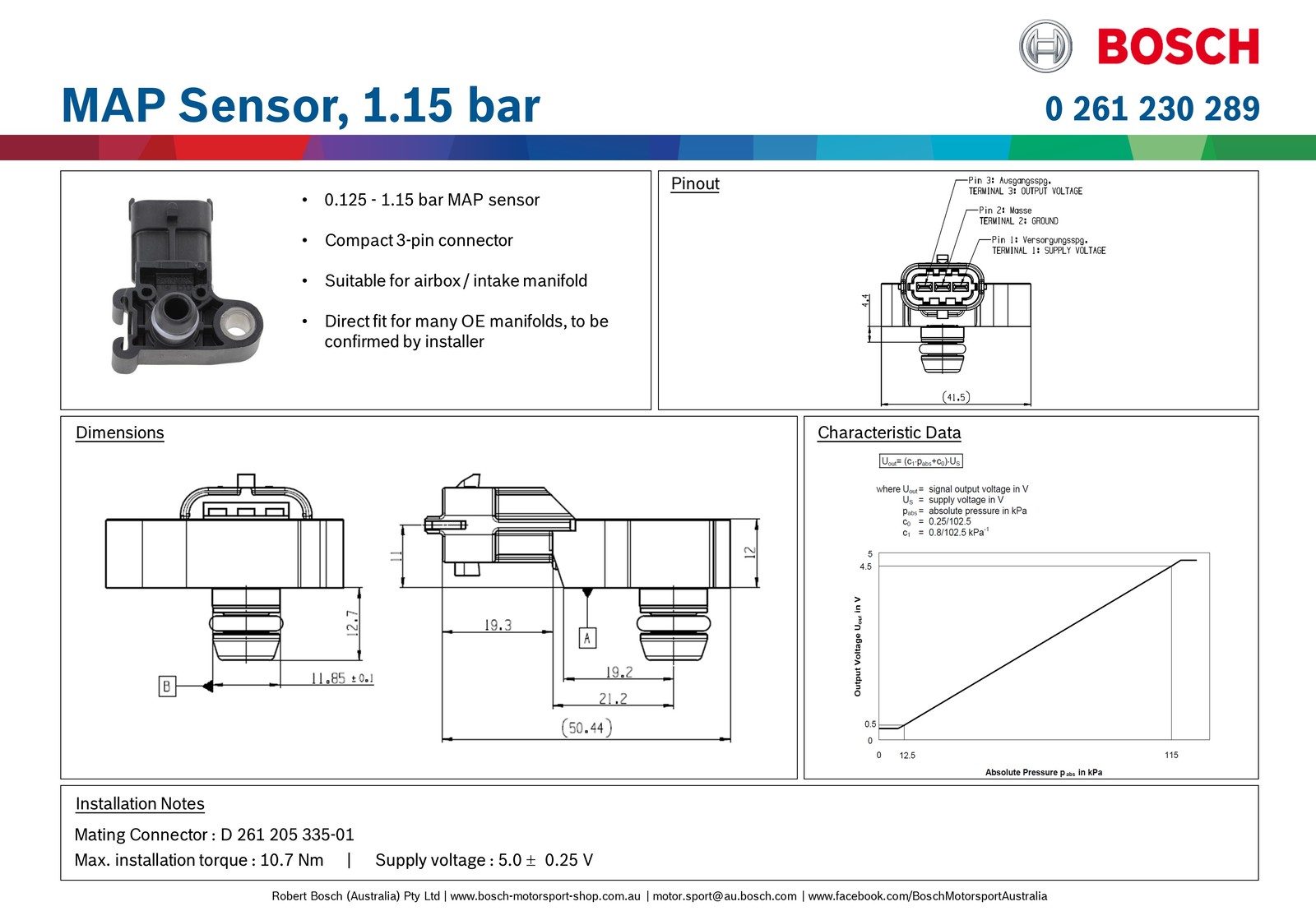

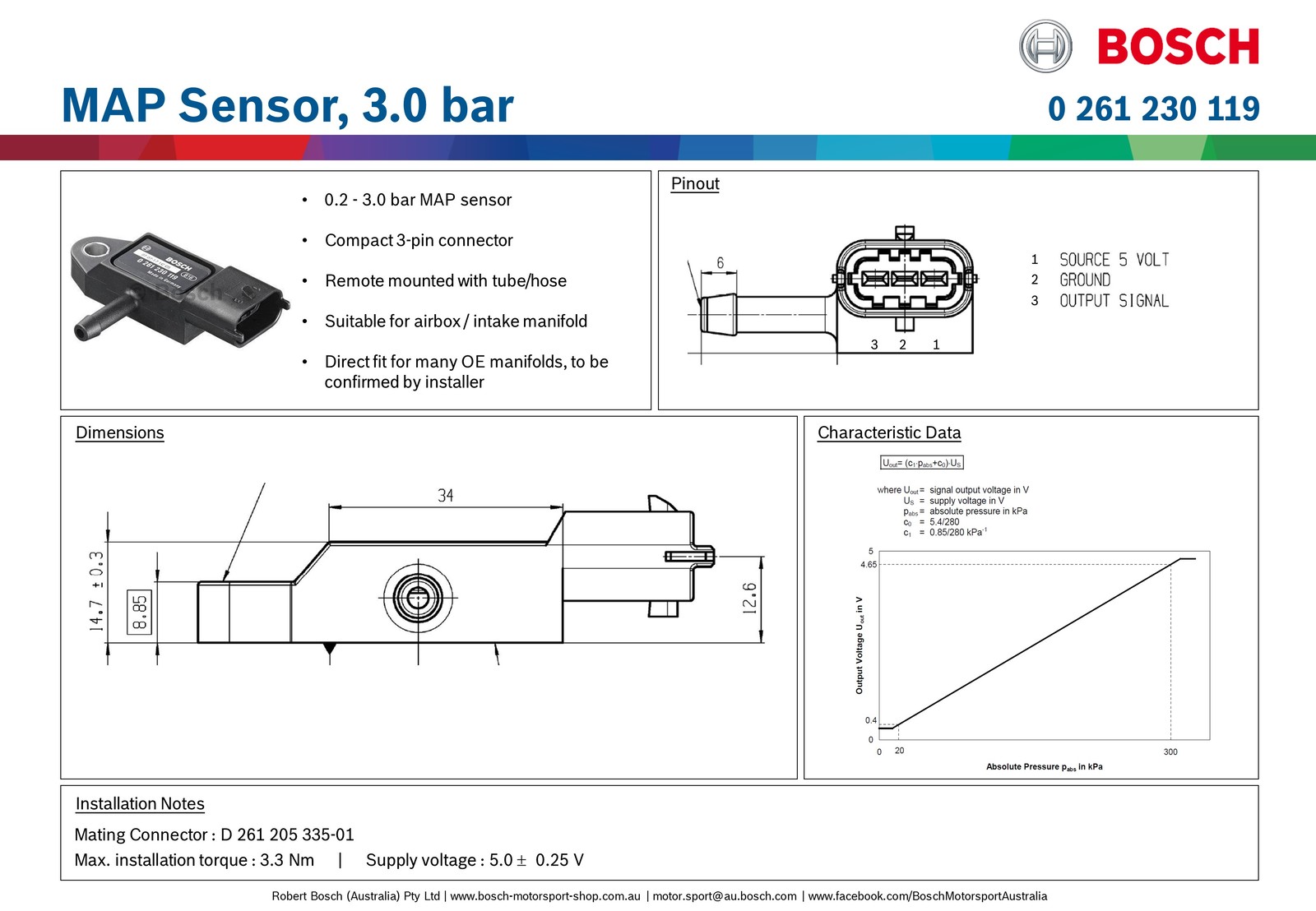

The Bosch 0 261 230 099 MAP sensor is a robust and reliable component designed to provide accurate and consistent readings of manifold pressure. It is typically installed in the intake manifold and connected to the ECU via a wiring harness.

Here’s a breakdown of its key features:

- Piezoresistive Sensing Element: This sensor employs a piezoresistive element, which changes its electrical resistance in response to pressure changes. This change in resistance is measured by the ECU, allowing it to determine the manifold pressure.

- Temperature Compensation: The sensor incorporates temperature compensation circuitry to ensure accurate readings even under varying ambient temperatures. This is crucial for maintaining precise fuel and ignition timing adjustments.

- Durability and Reliability: The Bosch 0 261 230 099 sensor is built to withstand the harsh environment of an engine compartment, including vibrations, temperature fluctuations, and potential exposure to contaminants.

- Wide Compatibility: This sensor is compatible with a wide range of automotive applications, making it a popular choice for various vehicle models and engine types.

Importance of a Functional MAP Sensor

A malfunctioning MAP sensor can have significant consequences for engine performance and overall vehicle operation.

- Poor Fuel Economy: An inaccurate MAP reading can lead to incorrect fuel-to-air ratios, resulting in inefficient combustion and reduced fuel economy.

- Engine Misfires and Stalling: Erratic readings from the MAP sensor can cause the ECU to miscalculate ignition timing, leading to misfires, rough idling, and even stalling.

- Emissions Issues: Incorrect fuel-to-air ratios can result in increased emissions, potentially exceeding regulatory limits.

- Check Engine Light: A faulty MAP sensor will often trigger the check engine light, indicating a need for diagnosis and repair.

Troubleshooting and Replacement

If you suspect a problem with your MAP sensor, it’s essential to have it diagnosed and potentially replaced.

Here are some common signs that your MAP sensor may be failing:

- Engine hesitation or rough idling: The engine may struggle to accelerate smoothly or exhibit rough idling.

- Check engine light illumination: The check engine light may illuminate, accompanied by a diagnostic code related to the MAP sensor.

- Reduced fuel economy: You may notice a significant drop in fuel efficiency.

- Engine stalling: The engine may stall, particularly at idle or during acceleration.

Replacing a faulty MAP sensor is a relatively straightforward process, but it’s recommended to consult a qualified mechanic for proper installation to avoid potential damage to the sensor or other engine components.

FAQs Regarding Bosch 0 261 230 099 MAP Sensor

Q: What vehicles is the Bosch 0 261 230 099 MAP sensor compatible with?

A: This sensor is commonly used in various vehicle models, including those manufactured by Volkswagen, Audi, Ford, and others. However, it’s crucial to verify compatibility with your specific vehicle year, make, and model before purchasing or installing the sensor.

Q: How do I test a Bosch 0 261 230 099 MAP sensor?

A: Testing a MAP sensor requires specialized equipment and technical expertise. It’s best to consult a qualified mechanic for accurate diagnosis and testing.

Q: What is the lifespan of a Bosch 0 261 230 099 MAP sensor?

A: The lifespan of a MAP sensor varies depending on factors like driving conditions, maintenance practices, and environmental factors. However, they are generally designed to last for several years under normal operating conditions.

Q: What are the potential risks associated with using a non-OEM MAP sensor?

A: Using a non-OEM MAP sensor may result in compatibility issues, inaccurate readings, and potential damage to the engine control system. It’s always recommended to use genuine OEM parts for optimal performance and longevity.

Tips for Maintaining a MAP Sensor

- Regular Engine Maintenance: Adhering to regular engine maintenance schedules, including oil changes, air filter replacements, and spark plug replacements, helps to maintain optimal engine conditions and minimize the risk of sensor malfunction.

- Avoid Exposure to Contaminants: Keep the engine compartment clean and avoid exposure to excessive dust, dirt, or other contaminants that can potentially damage the sensor.

- Use High-Quality Fuel: Using high-quality fuel can help prevent buildup of deposits in the intake manifold, which can affect the sensor’s accuracy.

- Professional Inspection: Regular professional inspections can help identify any potential issues with the MAP sensor before they lead to significant problems.

Conclusion

The Bosch 0 261 230 099 MAP sensor is a critical component in modern automotive engines, playing a vital role in ensuring optimal engine performance, fuel efficiency, and emissions control. Understanding its function, potential issues, and proper maintenance practices can help ensure the smooth and reliable operation of your vehicle. By proactively addressing any potential problems with the MAP sensor, you can avoid costly repairs and ensure that your engine operates at its peak performance.

Closure

Thus, we hope this article has provided valuable insights into Understanding the Bosch MAP Sensor: A Comprehensive Guide. We thank you for taking the time to read this article. See you in our next article!