Understanding the Crucial Role of Map Sensors: A Comprehensive Guide to Specifications and Applications

Related Articles: Understanding the Crucial Role of Map Sensors: A Comprehensive Guide to Specifications and Applications

Introduction

With great pleasure, we will explore the intriguing topic related to Understanding the Crucial Role of Map Sensors: A Comprehensive Guide to Specifications and Applications. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

Understanding the Crucial Role of Map Sensors: A Comprehensive Guide to Specifications and Applications

The manifold absolute pressure (MAP) sensor, a critical component in modern automotive engine management systems, plays a vital role in ensuring optimal engine performance and fuel efficiency. This sensor accurately measures the pressure within the intake manifold, providing valuable data to the engine control unit (ECU) for precise fuel and ignition timing adjustments. This article delves into the intricacies of MAP sensor specifications, highlighting their significance in achieving efficient engine operation and emissions control.

The Importance of MAP Sensor Specifications

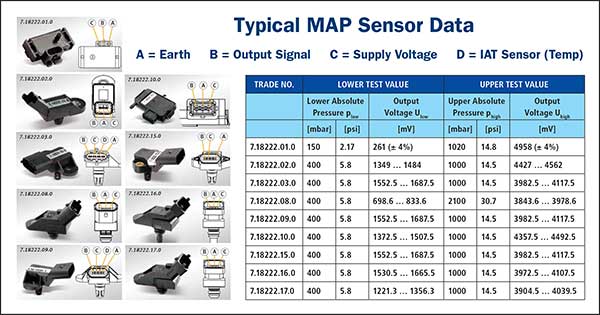

MAP sensor specifications define the sensor’s operational characteristics and performance parameters. These specifications are crucial for selecting the appropriate sensor for a specific application and ensuring its compatibility with the engine control system.

Key MAP Sensor Specifications:

-

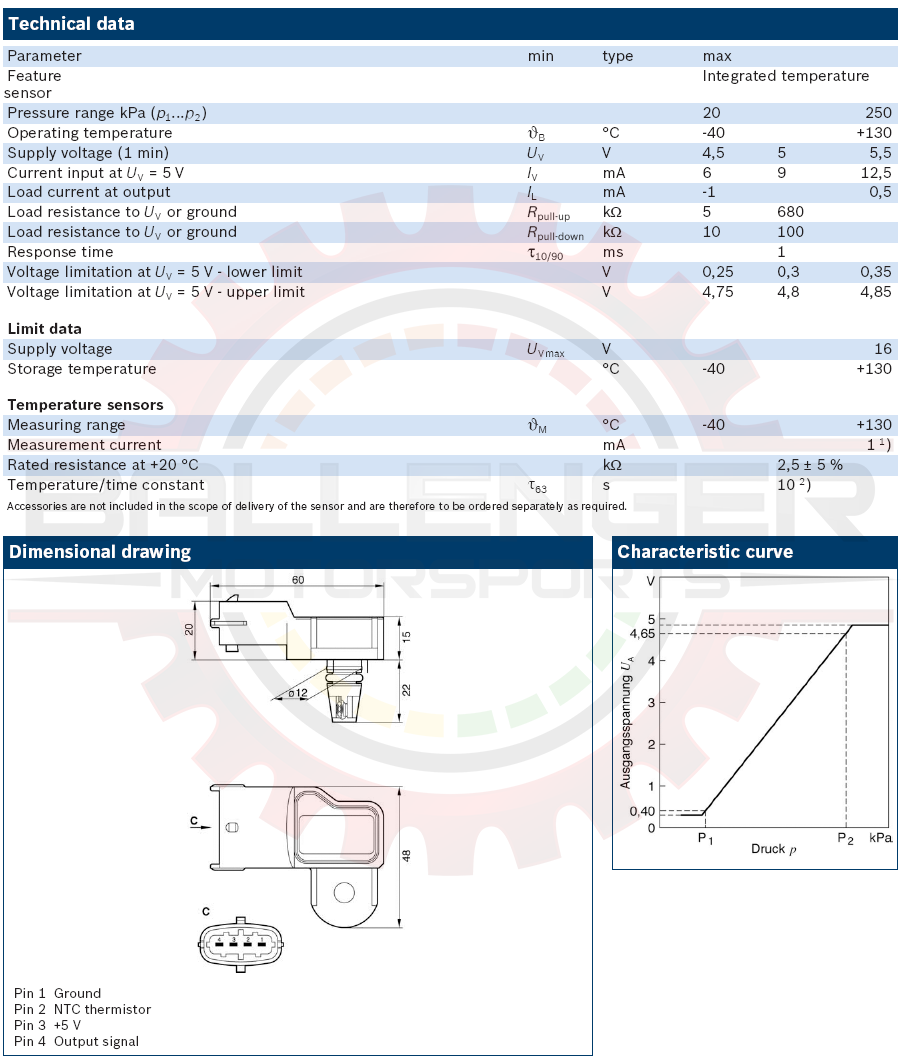

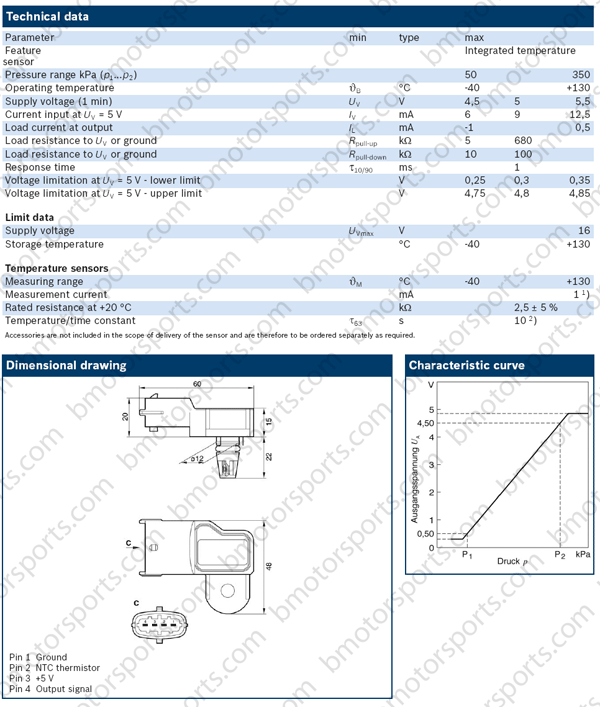

Operating Pressure Range: This specification defines the pressure range within which the sensor can accurately measure pressure. It is typically expressed in units of kilopascals (kPa) or pounds per square inch (psi). The operating pressure range must match the expected pressure conditions within the intake manifold of the engine.

-

Accuracy: MAP sensor accuracy refers to the sensor’s ability to provide precise pressure readings. It is usually expressed as a percentage of the full-scale output or as a specific pressure value. Higher accuracy ensures more precise engine control and fuel efficiency.

-

Response Time: This specification indicates how quickly the sensor can respond to changes in intake manifold pressure. Faster response times are essential for accurate control of engine parameters during dynamic driving conditions.

-

Temperature Range: The operating temperature range defines the temperature limits within which the sensor can function reliably. This specification is crucial for ensuring accurate operation in various ambient and engine temperatures.

-

Output Signal: MAP sensors typically provide an analog voltage or digital signal output. The output signal must be compatible with the ECU’s input requirements.

-

Output Voltage: For analog output sensors, the output voltage range is specified. This range typically corresponds to the measured pressure, with a higher voltage representing higher pressure.

-

Output Frequency: For digital output sensors, the output frequency is specified. The frequency varies proportionally to the measured pressure.

-

Mounting Type: MAP sensors can be mounted in various ways, such as threaded, flange-mounted, or surface-mounted. The mounting type must be compatible with the intake manifold design.

-

Electrical Connections: The sensor’s electrical connections must match the ECU’s wiring harness. This includes the number of pins, wire colors, and pin assignments.

Types of MAP Sensors:

- Piezoresistive Sensors: These sensors utilize a piezoresistive element whose resistance changes proportionally to the applied pressure. They are known for their high accuracy and fast response time.

- Capacitive Sensors: These sensors use a diaphragm that changes capacitance in response to pressure variations. They are typically robust and offer a wide operating pressure range.

- Strain Gauge Sensors: These sensors employ strain gauges that measure the deformation of a diaphragm due to pressure changes. They are known for their stability and reliability.

Benefits of Precise MAP Sensor Specifications:

- Improved Fuel Efficiency: Accurate pressure readings allow the ECU to precisely adjust fuel delivery, optimizing combustion and minimizing fuel consumption.

- Enhanced Engine Performance: Precise control of fuel and ignition timing based on accurate pressure measurements results in smoother engine operation, increased power output, and reduced emissions.

- Reduced Emissions: Optimal combustion achieved through precise pressure sensing minimizes harmful emissions, contributing to environmental protection.

- Increased Durability: Selecting a sensor with appropriate specifications ensures its longevity and reliability, minimizing the risk of premature failure.

FAQs on MAP Sensor Specifications:

1. How do I choose the right MAP sensor for my application?

To select the appropriate MAP sensor, consider the following factors:

- Engine type and size: The engine’s displacement and operating pressure range will determine the required pressure range of the sensor.

- ECU compatibility: The sensor’s output signal and electrical connections must match the ECU’s requirements.

- Operating environment: The temperature range and other environmental factors should be considered to ensure the sensor’s reliability.

2. What are the signs of a faulty MAP sensor?

Symptoms of a malfunctioning MAP sensor include:

- Rough idling: The engine may run unevenly at idle due to inaccurate fuel delivery.

- Poor acceleration: The engine may hesitate or struggle to accelerate due to incorrect fuel and ignition timing.

- Increased fuel consumption: A faulty sensor can lead to excessive fuel consumption due to improper fuel-air mixture.

- Check engine light: The ECU may detect a malfunctioning sensor and illuminate the check engine light.

3. How often should I replace my MAP sensor?

MAP sensors typically have a long lifespan, but they can wear out over time. Regular inspection and replacement as needed is recommended. Factors like engine conditions, driving habits, and environmental exposure can influence the sensor’s lifespan.

Tips for Using MAP Sensors Effectively:

- Ensure proper installation: The sensor should be installed securely and correctly to avoid leaks or damage.

- Regularly inspect for damage: Check for physical damage, cracks, or leaks in the sensor and its connections.

- Maintain clean intake manifold: A clean intake manifold ensures accurate pressure readings and optimal sensor performance.

- Use high-quality sensors: Selecting a sensor from a reputable manufacturer ensures reliability and longevity.

Conclusion:

MAP sensor specifications are crucial for achieving optimal engine performance, fuel efficiency, and emissions control. Understanding these specifications and their impact on engine operation is essential for selecting the right sensor for a specific application and ensuring its compatibility with the engine control system. By utilizing the right MAP sensor and maintaining it properly, vehicle owners can maximize engine performance, minimize fuel consumption, and contribute to a cleaner environment.

Closure

Thus, we hope this article has provided valuable insights into Understanding the Crucial Role of Map Sensors: A Comprehensive Guide to Specifications and Applications. We thank you for taking the time to read this article. See you in our next article!