Understanding the Ford Manifold Absolute Pressure (MAP) Sensor: A Crucial Component for Optimal Engine Performance

Related Articles: Understanding the Ford Manifold Absolute Pressure (MAP) Sensor: A Crucial Component for Optimal Engine Performance

Introduction

With great pleasure, we will explore the intriguing topic related to Understanding the Ford Manifold Absolute Pressure (MAP) Sensor: A Crucial Component for Optimal Engine Performance. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

Understanding the Ford Manifold Absolute Pressure (MAP) Sensor: A Crucial Component for Optimal Engine Performance

The manifold absolute pressure (MAP) sensor, often referred to simply as the MAP sensor, plays a critical role in the smooth and efficient operation of Ford vehicles. This sensor is an integral part of the engine control unit (ECU) system, providing vital information that allows the ECU to precisely regulate fuel injection and ignition timing. This article delves into the intricacies of the MAP sensor, exploring its function, location, troubleshooting, and maintenance, ultimately highlighting its significance in ensuring optimal engine performance.

The MAP Sensor: A Vital Link in the Engine Control System

The MAP sensor is a small, electronic device that measures the absolute pressure within the intake manifold. This pressure, known as manifold absolute pressure (MAP), reflects the amount of air being drawn into the engine during each intake stroke. The MAP sensor converts this pressure reading into an electrical signal that is transmitted to the ECU.

How the MAP Sensor Works: A Detailed Breakdown

The MAP sensor utilizes a diaphragm, a thin, flexible membrane, to detect pressure changes within the intake manifold. As the pressure in the manifold fluctuates, the diaphragm moves, altering the resistance within an internal electrical circuit. This change in resistance is interpreted by the ECU as a specific pressure reading. The ECU then uses this information to adjust several critical engine parameters, including:

- Fuel Injection: The ECU utilizes the MAP sensor data to determine the precise amount of fuel that needs to be injected into the engine cylinders for optimal combustion. This ensures a proper air-fuel mixture, maximizing engine efficiency and minimizing emissions.

- Ignition Timing: The MAP sensor reading also influences the timing of spark delivery. The ECU adjusts the ignition timing based on the pressure within the intake manifold, ensuring optimal combustion and maximizing power output.

- Other Engine Functions: In some vehicles, the MAP sensor data might also be used to regulate other engine functions such as idle speed control, exhaust gas recirculation (EGR) system operation, and even the operation of the variable valve timing (VVT) system.

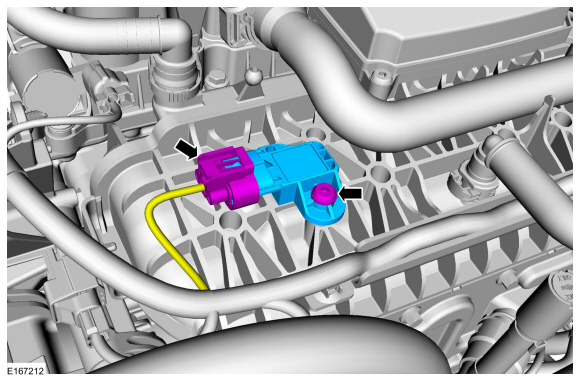

Location and Identification of the MAP Sensor

The MAP sensor is typically found in a convenient location within the engine bay, easily accessible for inspection and replacement. Common locations include:

- Intake Manifold: The MAP sensor is often mounted directly onto the intake manifold, allowing for a direct reading of the pressure within the manifold.

- Vacuum Line Connection: In some vehicles, the MAP sensor might be connected to the intake manifold via a vacuum line, providing a convenient access point for pressure readings.

Symptoms of a Faulty MAP Sensor: Recognizing the Warning Signs

A malfunctioning MAP sensor can significantly disrupt the smooth operation of the engine, leading to a range of symptoms that can indicate a problem:

- Engine Stalling: A faulty MAP sensor can provide inaccurate pressure readings to the ECU, leading to incorrect fuel injection and ignition timing, potentially causing the engine to stall, especially at idle.

- Rough Idle: Similar to stalling, a faulty MAP sensor can cause the engine to run rough, especially at idle, due to inconsistent fuel delivery and ignition timing.

- Poor Fuel Economy: An inaccurate pressure reading from the MAP sensor can lead to an overly rich or lean air-fuel mixture, resulting in reduced fuel efficiency and increased emissions.

- Reduced Power Output: A faulty MAP sensor can negatively impact engine performance, resulting in reduced power output and sluggish acceleration.

- Check Engine Light (CEL): The ECU often detects a malfunctioning MAP sensor and illuminates the check engine light, triggering a diagnostic trouble code (DTC) that can be retrieved using a scan tool.

Troubleshooting and Diagnosis: Identifying the Root Cause

If you suspect a faulty MAP sensor, a systematic approach to troubleshooting can help pinpoint the issue:

- Visual Inspection: Begin by visually inspecting the MAP sensor for any signs of damage, such as cracks, leaks, or corrosion.

- Vacuum Line Check: If the MAP sensor is connected via a vacuum line, inspect the line for any signs of blockage, leaks, or damage.

- Pressure Testing: Using a vacuum gauge or a pressure tester, check the pressure readings from the MAP sensor at different engine speeds and loads. Compare these readings to the manufacturer’s specifications to determine if the sensor is functioning correctly.

- Scan Tool Diagnosis: Utilize a scan tool to retrieve any diagnostic trouble codes (DTCs) related to the MAP sensor. These codes can provide valuable insights into the specific malfunctioning component.

Maintenance and Replacement: Ensuring Long-Term Performance

While the MAP sensor is generally a robust component, proper maintenance can extend its lifespan and prevent premature failure:

- Regular Inspection: As part of routine maintenance, visually inspect the MAP sensor for any signs of damage or wear.

- Vacuum Line Maintenance: Regularly check the vacuum line for any signs of blockage, leaks, or damage.

- Replacement: If the MAP sensor is malfunctioning or showing signs of wear, it is essential to replace it with a genuine Ford part or a high-quality aftermarket equivalent.

Frequently Asked Questions (FAQs) About the MAP Sensor

Q: What is the difference between a MAP sensor and a MAF sensor?

A: Both the MAP sensor and the Mass Air Flow (MAF) sensor are critical components in the engine control system, but they measure different aspects of the air intake:

- MAP Sensor: Measures the absolute pressure within the intake manifold, reflecting the amount of air drawn into the engine.

- MAF Sensor: Measures the mass of air flowing into the engine, providing a more accurate measure of air intake.

Q: Can I clean a MAP sensor?

A: While some people attempt to clean MAP sensors, it is generally not recommended. Cleaning can damage the delicate internal components of the sensor, leading to further malfunctions. It is best to replace a faulty MAP sensor with a new one.

Q: Can a faulty MAP sensor cause a car to run rich?

A: Yes, a faulty MAP sensor can provide inaccurate pressure readings to the ECU, leading to an overly rich air-fuel mixture. This can result in reduced fuel economy and increased emissions.

Q: How can I test a MAP sensor without a scan tool?

A: While a scan tool provides the most accurate diagnosis, you can perform a basic test using a vacuum gauge or a pressure tester. Compare the pressure readings at different engine speeds and loads to the manufacturer’s specifications to determine if the sensor is functioning correctly.

Tips for Maintaining a Healthy MAP Sensor

- Regular Maintenance: As part of routine maintenance, visually inspect the MAP sensor for any signs of damage or wear.

- Vacuum Line Inspection: Regularly check the vacuum line for any signs of blockage, leaks, or damage.

- Quality Replacement Parts: If the MAP sensor needs replacement, use genuine Ford parts or high-quality aftermarket equivalents.

- Professional Diagnosis: If you suspect a faulty MAP sensor, seek professional diagnosis and repair to ensure proper operation.

Conclusion: A Vital Component for Optimal Engine Performance

The MAP sensor is an indispensable component of the engine control system in Ford vehicles. Its accurate pressure readings enable the ECU to precisely regulate fuel injection and ignition timing, ensuring optimal engine performance, fuel efficiency, and emissions control. Recognizing the symptoms of a faulty MAP sensor and understanding the importance of proper maintenance can help drivers avoid costly repairs and ensure the long-term health of their Ford vehicles. By maintaining the MAP sensor and addressing any issues promptly, drivers can enjoy the full potential of their vehicle’s engine, experiencing smooth performance and optimal fuel economy.

Closure

Thus, we hope this article has provided valuable insights into Understanding the Ford Manifold Absolute Pressure (MAP) Sensor: A Crucial Component for Optimal Engine Performance. We hope you find this article informative and beneficial. See you in our next article!