Understanding the Holley 3-Bar MAP Sensor: A Comprehensive Guide

Related Articles: Understanding the Holley 3-Bar MAP Sensor: A Comprehensive Guide

Introduction

In this auspicious occasion, we are delighted to delve into the intriguing topic related to Understanding the Holley 3-Bar MAP Sensor: A Comprehensive Guide. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

Understanding the Holley 3-Bar MAP Sensor: A Comprehensive Guide

The Holley 3-Bar MAP sensor, a critical component in modern automotive engine management systems, plays a pivotal role in optimizing engine performance and fuel efficiency. This sensor, known as a Manifold Absolute Pressure (MAP) sensor, measures the pressure within the intake manifold, providing the engine control unit (ECU) with vital information for accurate fuel injection and ignition timing adjustments.

This article delves into the intricacies of the Holley 3-Bar MAP sensor, exploring its function, operation, installation, and the benefits it offers to automotive enthusiasts.

The Fundamentals of MAP Sensors

MAP sensors are crucial for modern engines equipped with electronic fuel injection systems. They serve as the eyes and ears of the ECU, enabling it to determine the amount of air entering the engine. This information is crucial for precise fuel delivery, as the ECU uses it to calculate the ideal air-fuel mixture for optimal combustion.

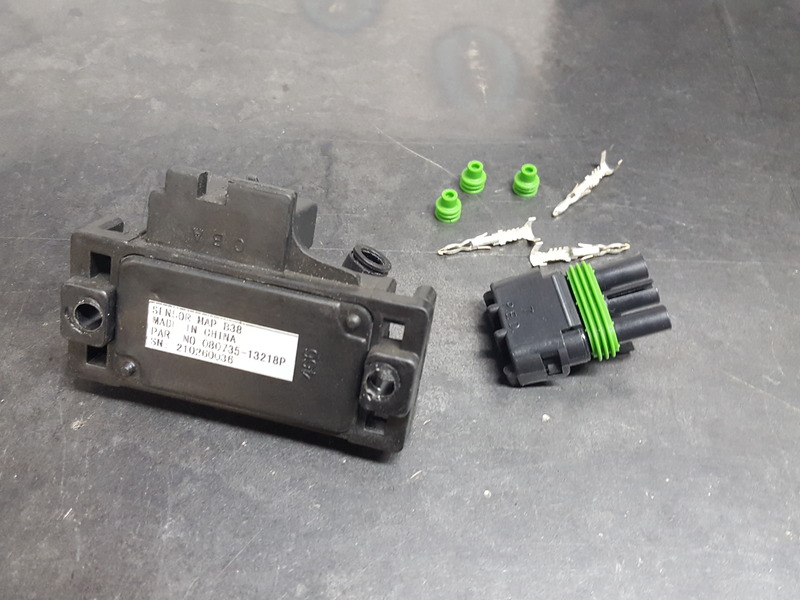

The Holley 3-Bar MAP Sensor: A Detailed Look

The Holley 3-Bar MAP sensor stands out from its counterparts with its ability to measure a wider range of pressure, encompassing both low and high manifold pressures. This capability is particularly beneficial for high-performance engines and those with forced induction systems, such as turbochargers and superchargers, where manifold pressure can fluctuate significantly.

How the Holley 3-Bar MAP Sensor Works

The Holley 3-Bar MAP sensor utilizes a piezoelectric element, a material that generates an electrical charge when subjected to pressure. This element is housed within a sealed chamber, and as manifold pressure changes, it deforms, altering the electrical charge. This change in electrical charge is then translated into a voltage signal by the sensor’s internal circuitry. The ECU interprets this voltage signal, correlating it to the specific manifold pressure, and uses this data to adjust fuel delivery and ignition timing accordingly.

Benefits of Using a Holley 3-Bar MAP Sensor

The Holley 3-Bar MAP sensor offers several advantages, particularly for performance-oriented applications:

- Enhanced Fuel Efficiency: By accurately measuring manifold pressure, the sensor enables the ECU to fine-tune fuel delivery, ensuring an optimal air-fuel mixture for each engine load and speed. This precision leads to improved fuel economy and reduced emissions.

- Improved Engine Performance: Precise fuel delivery, coupled with optimized ignition timing based on manifold pressure readings, translates into smoother engine operation, increased power output, and a more responsive throttle.

- Increased Tuning Flexibility: The Holley 3-Bar MAP sensor’s wider pressure range allows for more precise tuning of high-performance engines, particularly those equipped with forced induction systems. This capability enables enthusiasts to fine-tune boost pressure and other parameters for optimal performance.

- Enhanced Reliability: Holley 3-Bar MAP sensors are renowned for their durability and reliability, ensuring accurate readings and consistent performance over time.

Installation and Calibration

Installing a Holley 3-Bar MAP sensor typically involves replacing the existing sensor with the new unit. The installation process varies depending on the specific vehicle and engine setup, and it’s always recommended to consult the manufacturer’s instructions and seek professional assistance if needed.

Once installed, the sensor may require calibration to ensure accurate readings. This process involves adjusting the sensor’s output voltage to match the ECU’s expectations. Calibration can be achieved through specialized software or by using a digital multimeter to measure the sensor’s output voltage under specific conditions.

Troubleshooting and Common Issues

While Holley 3-Bar MAP sensors are known for their reliability, they can experience issues over time. Some common problems include:

- Faulty Sensor: A malfunctioning sensor can provide inaccurate readings, leading to engine performance issues.

- Electrical Problems: Damaged wiring or loose connections can interrupt the signal flow between the sensor and the ECU, resulting in erratic engine behavior.

- Vacuum Leaks: Leaks in the intake manifold or vacuum lines can disrupt the pressure readings, leading to inaccurate sensor data.

FAQs about the Holley 3-Bar MAP Sensor

Q: What is the difference between a 1-bar and a 3-bar MAP sensor?

A: The primary difference lies in the pressure range they can measure. A 1-bar sensor is suitable for naturally aspirated engines, while a 3-bar sensor is designed for high-performance applications, including turbocharged and supercharged engines, due to their ability to handle higher manifold pressures.

Q: Can I use a 3-bar MAP sensor on a naturally aspirated engine?

A: While it’s technically possible, it’s not recommended. The 3-bar sensor’s wider pressure range might not be fully utilized in a naturally aspirated engine, and it might not be compatible with the ECU’s calibration parameters.

Q: Can I install a Holley 3-Bar MAP sensor without calibration?

A: It’s not advisable. While the sensor might function, it’s crucial to calibrate it to ensure accurate readings and optimal engine performance.

Q: How often should I replace my MAP sensor?

A: MAP sensors are typically quite durable, but they can wear out over time. If you notice any performance issues or suspect a malfunctioning sensor, it’s recommended to replace it.

Tips for Maintaining and Using a Holley 3-Bar MAP Sensor

- Regular Inspection: Periodically inspect the sensor for signs of damage or corrosion.

- Clean Connections: Ensure the electrical connections are clean and secure to prevent signal interruptions.

- Avoid Contamination: Protect the sensor from oil and debris, as these can interfere with its operation.

- Professional Installation: For optimal performance and reliability, consider professional installation and calibration.

Conclusion

The Holley 3-Bar MAP sensor is an essential component for enhancing engine performance and fuel efficiency in modern automotive applications. Its ability to measure a wider range of manifold pressures, coupled with its accuracy and reliability, makes it an ideal choice for high-performance engines and those equipped with forced induction systems. By understanding the sensor’s function, installation, and maintenance requirements, enthusiasts can harness its capabilities to unlock the full potential of their engines.

Closure

Thus, we hope this article has provided valuable insights into Understanding the Holley 3-Bar MAP Sensor: A Comprehensive Guide. We appreciate your attention to our article. See you in our next article!