Understanding the Manifold Absolute Pressure Sensor: A Comprehensive Guide

Related Articles: Understanding the Manifold Absolute Pressure Sensor: A Comprehensive Guide

Introduction

With great pleasure, we will explore the intriguing topic related to Understanding the Manifold Absolute Pressure Sensor: A Comprehensive Guide. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

Understanding the Manifold Absolute Pressure Sensor: A Comprehensive Guide

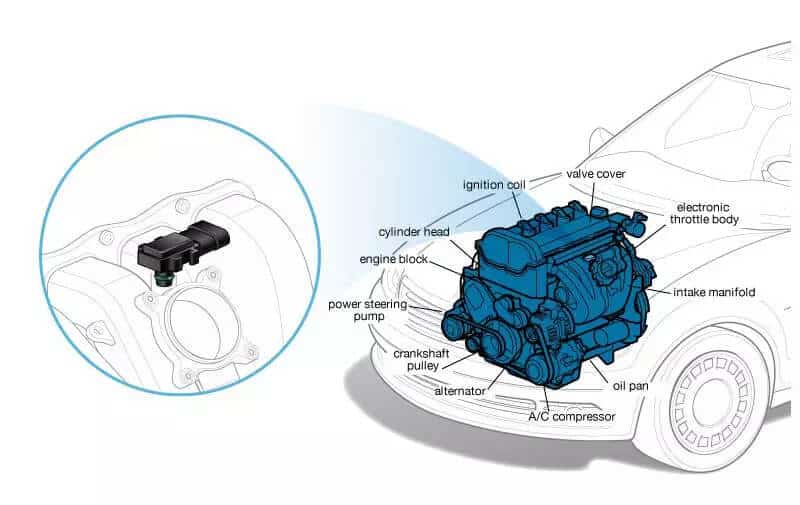

The manifold absolute pressure (MAP) sensor is an integral component in modern internal combustion engines, playing a crucial role in optimizing fuel efficiency and reducing emissions. This sensor measures the pressure within the engine’s intake manifold, providing vital information to the engine control unit (ECU) for precise fuel and ignition timing adjustments.

The Function of the MAP Sensor

The intake manifold is the conduit through which air enters the engine cylinders. The MAP sensor, typically located within the intake manifold or on a nearby pipe, measures the absolute pressure within this manifold. This pressure, known as manifold absolute pressure (MAP), is a direct indication of the amount of air entering the engine.

The ECU utilizes this MAP data in conjunction with other sensor inputs, such as throttle position, engine speed, and air temperature, to calculate the optimal air-fuel mixture required for combustion. This intricate calculation ensures efficient fuel combustion, minimizing fuel consumption and harmful emissions.

Common Causes of MAP Sensor Failure

While the MAP sensor is a robust component, it can malfunction due to various factors. Understanding these common causes can help diagnose and address sensor issues effectively.

- Contamination: The MAP sensor’s diaphragm, responsible for pressure sensing, can become contaminated by dust, dirt, oil, or other debris. This contamination can impede the diaphragm’s movement, leading to inaccurate pressure readings.

- Electrical Malfunctions: The sensor’s electrical connections can become loose, corroded, or damaged, disrupting the flow of information between the sensor and the ECU.

- Vacuum Leaks: A leak in the intake manifold or vacuum lines can lead to incorrect pressure readings, as the MAP sensor is measuring the pressure within the manifold. These leaks can be caused by damaged hoses, cracked manifold components, or loose connections.

- Sensor Degradation: Over time, the MAP sensor’s internal components, such as the diaphragm or the sensing element, can degrade due to wear and tear, leading to inaccurate pressure readings.

- Environmental Factors: Extreme temperatures, moisture, and vibration can also contribute to sensor failure, impacting its sensitivity and accuracy.

Symptoms of a Failing MAP Sensor

A malfunctioning MAP sensor can manifest in a variety of symptoms, indicating a need for inspection and potential replacement.

- Engine Stalling or Rough Idle: An inaccurate MAP reading can lead to incorrect fuel delivery, resulting in stalling or rough idling, particularly at idle or during acceleration.

- Poor Fuel Economy: The engine’s inability to accurately adjust the air-fuel mixture can lead to increased fuel consumption, reducing overall fuel efficiency.

- Reduced Power: A faulty MAP sensor can cause a decrease in engine power, as the engine may not be receiving the correct amount of fuel for optimal combustion.

- Check Engine Light (CEL): The ECU will often detect a faulty MAP sensor and illuminate the check engine light, accompanied by a corresponding diagnostic trouble code (DTC).

- Emissions Issues: A malfunctioning MAP sensor can lead to increased emissions, as the engine may not be operating at its optimal air-fuel ratio.

Diagnosing a Failing MAP Sensor

Diagnosing a faulty MAP sensor typically involves a combination of visual inspection, pressure testing, and diagnostic scanning.

- Visual Inspection: Inspect the MAP sensor for any signs of damage, contamination, or loose connections.

- Pressure Testing: Utilize a vacuum gauge or a pressure tester to verify the actual pressure within the intake manifold, comparing it to the readings provided by the MAP sensor.

- Diagnostic Scanning: Use an OBD-II scanner to retrieve any diagnostic trouble codes (DTCs) related to the MAP sensor. These codes can provide valuable information about the specific nature of the sensor failure.

Replacing a Faulty MAP Sensor

If a failing MAP sensor is identified, it is crucial to replace it with a new, compatible sensor.

- Choosing the Right Replacement: Ensure the replacement sensor is specifically designed for your vehicle’s make, model, and engine type.

- Installation Procedure: Refer to your vehicle’s repair manual or consult a qualified mechanic for proper installation procedures. The sensor is typically secured with a few bolts or clips.

- Testing and Resetting: After installation, test the new sensor for proper functionality. Clear any stored diagnostic trouble codes using an OBD-II scanner.

FAQs on MAP Sensor Causes

Q: What are the most common reasons for a MAP sensor to fail?

A: The most common reasons for MAP sensor failure include contamination, electrical malfunctions, vacuum leaks, sensor degradation, and environmental factors.

Q: How can I tell if my MAP sensor is bad?

A: Symptoms of a failing MAP sensor include engine stalling or rough idle, poor fuel economy, reduced power, check engine light illumination, and emissions issues.

Q: Can I drive with a bad MAP sensor?

A: While you may be able to drive with a faulty MAP sensor for a short period, it is not recommended. A malfunctioning sensor can lead to performance issues, increased fuel consumption, and potentially damage to other engine components.

Q: How much does it cost to replace a MAP sensor?

A: The cost of replacing a MAP sensor varies depending on the vehicle make, model, and labor costs. However, the sensor itself is generally inexpensive, and the replacement cost is typically affordable.

Q: How often should I check my MAP sensor?

A: While there is no specific schedule for checking the MAP sensor, it is advisable to inspect it during routine maintenance checks or if you suspect any issues with the engine’s performance.

Tips for Maintaining the MAP Sensor

- Regular Cleaning: Regularly clean the MAP sensor’s housing and surrounding area to prevent dust, dirt, and debris buildup.

- Inspecting Connections: Periodically inspect the sensor’s electrical connections for any signs of corrosion or looseness.

- Checking for Leaks: Regularly check for leaks in the intake manifold and vacuum lines.

Conclusion

The manifold absolute pressure (MAP) sensor plays a vital role in optimizing engine performance and reducing emissions. Understanding the common causes of MAP sensor failure, recognizing the symptoms, and knowing how to diagnose and replace the sensor are crucial for maintaining optimal engine health. By addressing any issues promptly and ensuring proper maintenance, you can ensure your vehicle’s engine operates efficiently and reliably for years to come.

Closure

Thus, we hope this article has provided valuable insights into Understanding the Manifold Absolute Pressure Sensor: A Comprehensive Guide. We hope you find this article informative and beneficial. See you in our next article!